As a consultant, I understand the critical role that high-performance insulation plays in industrial environments. Today, we’re diving deep into Industrial IMO FEF (Flexible Elastomeric Foam) insulation – a game-changer for various applications, and a key solution Gitco-sa.com proudly offers.

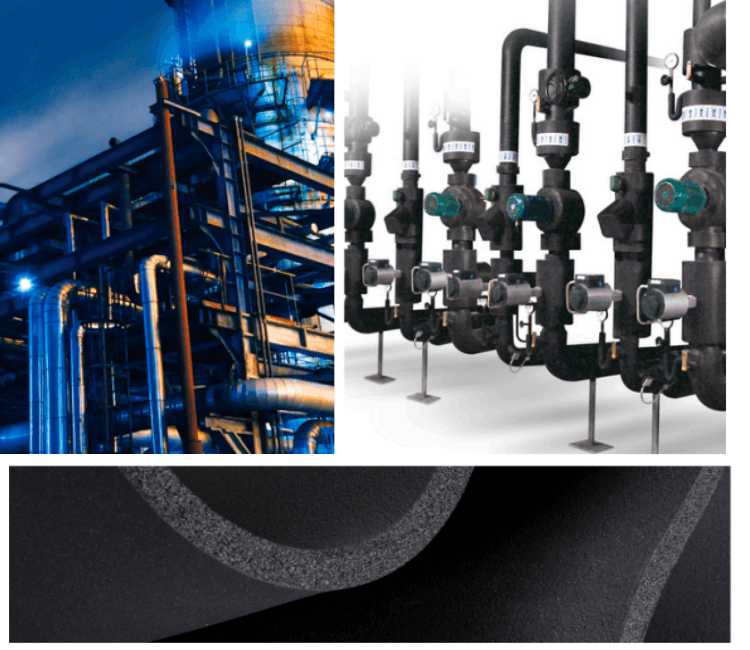

In the demanding world of industrial operations, efficiency, safety, and longevity are paramount. From sprawling petrochemical plants to intricate marine vessels, the control of temperature and prevention of condensation are not just desirable; they’re essential for operational integrity, energy conservation, and personnel safety. This is where Industrial IMO FEF insulation steps in, offering a robust and versatile solution.

Table of Contents

What Exactly is Industrial IMO FEF Insulation?

At its core, IMO FEF insulation is a closed-cell, flexible elastomeric foam specifically engineered to meet the stringent fire safety standards set by the International Maritime Organization (IMO). These regulations, particularly the FTP (Fire Test Procedures) Code, ensure that materials used in marine applications possess exceptional fire resistance properties. However, the benefits of IMO FEF extend far beyond the maritime industry, making it a compelling choice for a wide range of industrial applications where safety and performance are non-negotiable.

Key Characteristics and Benefits that Set IMO FEF Apart:

- Exceptional Fire Performance: This is the hallmark of IMO FEF. It’s designed to resist ignition, limit flame spread, and minimize smoke emission – crucial factors in containing fire and ensuring safe evacuation in critical environments. Meeting standards like IMO FTP Code Parts 5 and 2 (surface flammability and smoke/toxicity) provides a significant safety advantage.

- Superior Thermal Insulation: The closed-cell structure of FEF provides excellent thermal conductivity (low k-value), effectively minimizing heat loss or gain. This translates directly into significant energy savings, reduced operational costs, and a more stable process temperature.

- Effective Condensation Control: The inherent closed-cell nature also makes IMO FEF highly resistant to moisture ingress. This is vital in preventing condensation, which can lead to corrosion, mold growth, and compromised insulation performance, especially in humid or temperature-differential environments common in industrial settings.

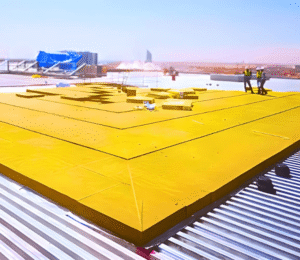

- Durability and Flexibility: FEF is known for its flexibility, making it easy to install around complex shapes, pipes, and equipment. Its inherent elasticity also provides good resistance to mechanical stress and impact, contributing to a longer service life.

- Chemical Resistance: Industrial environments often involve exposure to various chemicals. IMO FEF exhibits good resistance to many oils, greases, and diluted chemicals, ensuring its integrity and performance over time.

- Sound Absorption Properties: While not its primary function, the elastomeric nature of FEF offers some level of sound dampening, contributing to a slightly quieter working environment.

- Ease of Installation and Maintenance: The flexibility and lightweight nature of IMO FEF make it relatively easy to handle and install, reducing labor costs and installation time. Its closed-cell structure also simplifies maintenance as it’s less prone to absorbing dirt and moisture.

Why Choose Industrial IMO FEF Insulation for Your Applications?

The selection of insulation is a critical decision with long-term implications. Here’s why IMO FEF insulation, offered by Gitco-sa.com, should be a strong contender for your industrial needs:

- Uncompromising Safety: In industries where fire hazards are a significant concern (e.g., oil and gas, chemical processing, and marine), the superior fire performance of IMO FEF provides an invaluable layer of safety and helps meet stringent regulatory requirements.

- Long-Term Cost Savings: The combination of excellent thermal insulation and condensation control leads to substantial energy savings over the lifespan of the installation. Reduced corrosion and mold growth also minimize maintenance and replacement costs.

- Enhanced Operational Efficiency: Maintaining stable process temperatures is crucial for many industrial processes. IMO FEF helps ensure this stability, leading to improved efficiency and product quality.

- Environmental Responsibility: By reducing energy consumption, IMO FEF contributes to a lower carbon footprint and supports sustainability initiatives.

- Versatile Applications: Its unique properties make IMO FEF suitable for a wide array of industrial applications, including:

- Piping and Ductwork: Insulating hot, cold, and cryogenic pipelines to prevent heat loss/gain and condensation.

- Tanks and Vessels: Maintaining stable temperatures and preventing condensation on storage tanks and process vessels.

- HVAC Systems: Insulating air conditioning ducts and equipment for energy efficiency and condensation control.

- Marine Applications: Insulating pipes, ducts, and equipment on ships, offshore platforms, and other marine structures to meet IMO fire safety regulations.

- Industrial Equipment: Insulating machinery and equipment for thermal management and personnel protection.

Gitco-sa.com: Your Trusted Partner for Industrial IMO FEF Insulation in Saudi Arabia

At Gitco-sa.com, we understand the unique demands of industrial insulation. We offer a comprehensive range of high-quality Industrial IMO FEF insulation products that meet stringent international standards. Our team of experienced professionals can provide expert guidance to help you select the right insulation solution for your specific application, ensuring optimal performance, safety, and cost-effectiveness.

When you choose Gitco-sa.com for your Industrial IMO FEF insulation needs, you benefit from:

- Premium Quality Products: We source our insulation materials from reputable manufacturers, ensuring consistent quality and performance.

- Expert Technical Support: Our knowledgeable team can provide technical advice on material selection, installation best practices, and compliance with relevant regulations.

- Comprehensive Solutions: We offer a range of thicknesses and formats to suit diverse industrial applications.

- Reliable Supply and Delivery: We are committed to providing timely and efficient delivery to your project site.

Industrial IMO FEF Insulation – Frequently Asked Questions:

Industrial IMO FEF (Flexible Elastomeric Foam) insulation is a specialized material designed for demanding industrial and offshore environments that require compliance with the International Maritime Organization (IMO) standards for fire safety. Here are 20 frequently asked questions about Industrial IMO FEF Insulation:

- What does IMO FEF insulation stand for? IMO FEF insulation refers to Flexible Elastomeric Foam insulation that meets the fire safety standards and regulations set forth by the International Maritime Organization (IMO), particularly for marine and offshore applications.

- Why is IMO compliance important for industrial insulation? IMO compliance ensures that insulation materials used in marine and offshore environments have undergone rigorous fire safety testing, minimizing the risk of fire spread, smoke generation, and toxic emissions, thus protecting lives and assets.

- What are the key fire safety properties of IMO FEF insulation? Key properties include low flame spread, low smoke generation, and no production of burning droplets, as per IMO FTP (Fire Test Procedures) Code. Specific parts of the code (e.g., Part 2 and Part 5) are often referenced.

- What type of material is Industrial IMO FEF insulation typically made from? It is usually made from synthetic rubber-based foam, such as Nitrile Butadiene Rubber (NBR) or Ethylene Propylene Diene Monomer (EPDM), engineered to meet the stringent fire safety requirements.

- What are the typical applications for Industrial IMO FEF insulation? It is primarily used for thermal insulation and condensation control on pipes, vessels, ducts, and equipment in offshore platforms, marine vessels, and other industrial facilities where IMO compliance is mandatory or highly recommended.

- Does Industrial IMO FEF insulation offer thermal insulation properties? Yes, like other FEF insulation types, it provides excellent thermal insulation due to its closed-cell structure and low thermal conductivity, helping to conserve energy and maintain process temperatures.

- Is Industrial IMO FEF insulation resistant to moisture? Yes, the closed-cell structure provides inherent resistance to water vapor transmission, which helps prevent condensation and corrosion under the insulation (CUI), crucial in humid marine and industrial environments.

- What is the service temperature range of Industrial IMO FEF insulation? The service temperature range can vary depending on the specific product, but it generally ranges from -50°C to +110°C or even up to +150°C for certain high-temperature variants.

- Is Industrial IMO FEF insulation resistant to chemicals and oils? Many Industrial IMO FEF insulation products offer good resistance to various chemicals and oils commonly found in industrial and offshore settings. Specific resistance should be checked with the manufacturer’s data sheet.

- Is Industrial IMO FEF insulation mechanically robust? Yes, products like HT/ArmaFlex Industrial IMO are often designed to be high-density and mechanically robust to withstand the demanding conditions of industrial and offshore environments.

- Does Industrial IMO FEF insulation contribute to noise reduction? While primarily for thermal insulation and fire safety, some Industrial IMO FEF insulation products can contribute to acoustic insulation, especially when used as part of a multi-layer system like ArmaSound Industrial Systems.

- Is Industrial IMO FEF insulation easy to install? Yes, being flexible and available in tubes and sheets, it can be easily cut and installed around complex shapes like pipes and fittings. Proper adhesive, like ArmaFlex 520 or HT625, is recommended for secure joints.

- Does Industrial IMO FEF insulation require any special coverings? While it offers good resistance to weathering, for prolonged outdoor exposure or harsh mechanical environments, a protective covering like Arma-Chek R or metal jacketing might be recommended.

- What are the common brands offering Industrial IMO FEF insulation? Armacell (with their HT/ArmaFlex Industrial IMO and LT/ArmaFlex Industrial IMO) and K-Flex are prominent manufacturers of IMO-compliant FEF insulation for industrial applications.

- Does Industrial IMO FEF insulation have low leachable chloride content? Yes, many high-quality Industrial IMO FEF insulation products have low leachable chloride content (typically < 30-100 ppm) to minimize the risk of stress corrosion cracking (SCC), especially important when insulating stainless steel.

- What are the different IMO FTP Code parts relevant to this insulation? The most relevant parts are typically Part 2 (Smoke and Toxicity Test) and Part 5 (Surface Flammability Test) of the IMO 2010 FTP Code.

- Is Industrial IMO FEF insulation suitable for cryogenic applications? While standard IMO FEF insulation has a lower temperature limit around -50°C, some specialized FEF materials can be used for lower temperatures. Always check the specific product datasheet.

- Does the density of Industrial IMO FEF insulation matter? Yes, higher density often indicates greater mechanical robustness and can contribute to better acoustic performance in multi-layer systems.

- Where can I find technical data sheets for specific Industrial IMO FEF insulation products? Technical data sheets are usually available on the manufacturers’ websites (e.g., Armacell, K-Flex) and potentially on Gitco-sa.com’s product pages.

- How can Gitco-sa.com help with Industrial IMO FEF insulation needs? Gitco-sa.com can provide information, supply, and potentially offer installation guidance for various Industrial IMO FEF insulation products to meet the specific requirements of your marine, offshore, or industrial projects. Contact our team for inquiries and solutions.