Getzner Acoustic Floor Blocks (AFB): Floating Floor Soundproofing

Getzner Acoustic Floor Blocks (AFB) are high-performance elastomer point bearings, essential for creating floating floors with exceptional impact sound insulation. Ideal for demanding acoustic environments, these blocks are available in a complete range at Gitco-sa.com across Saudi Arabia.

Description

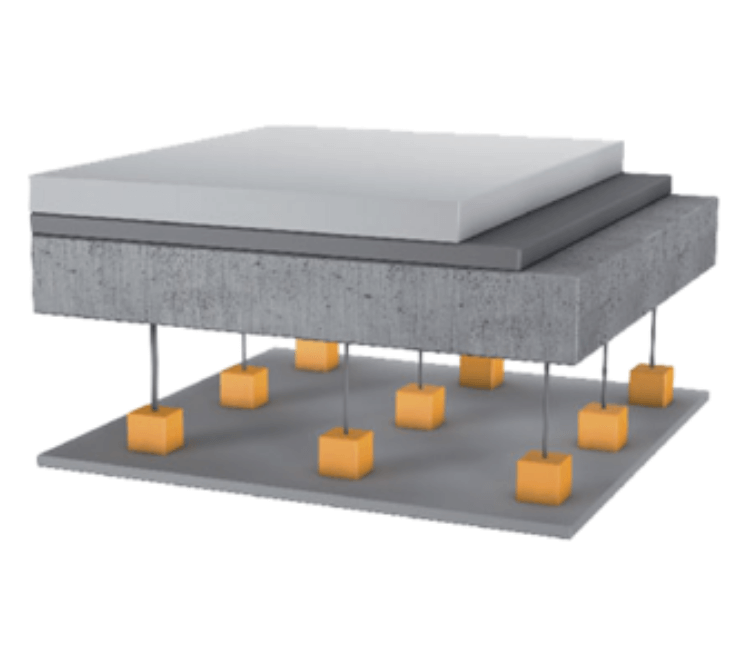

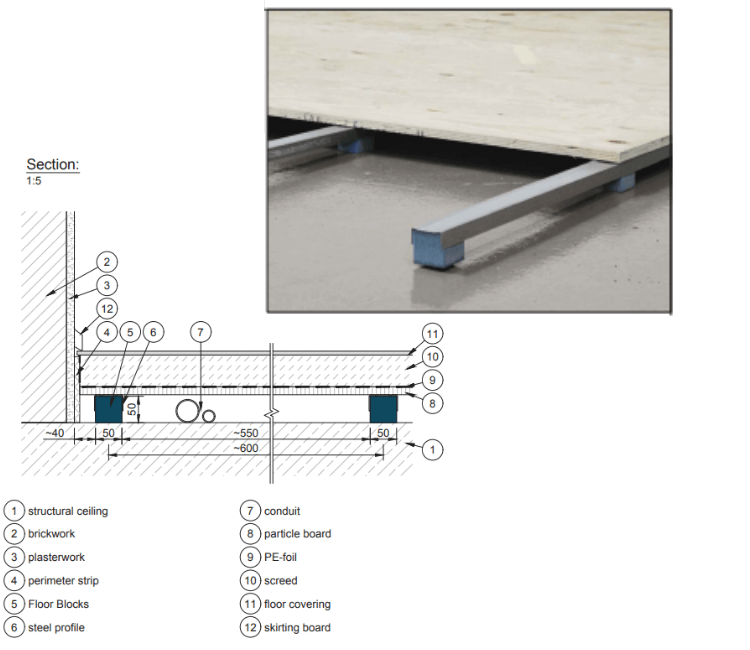

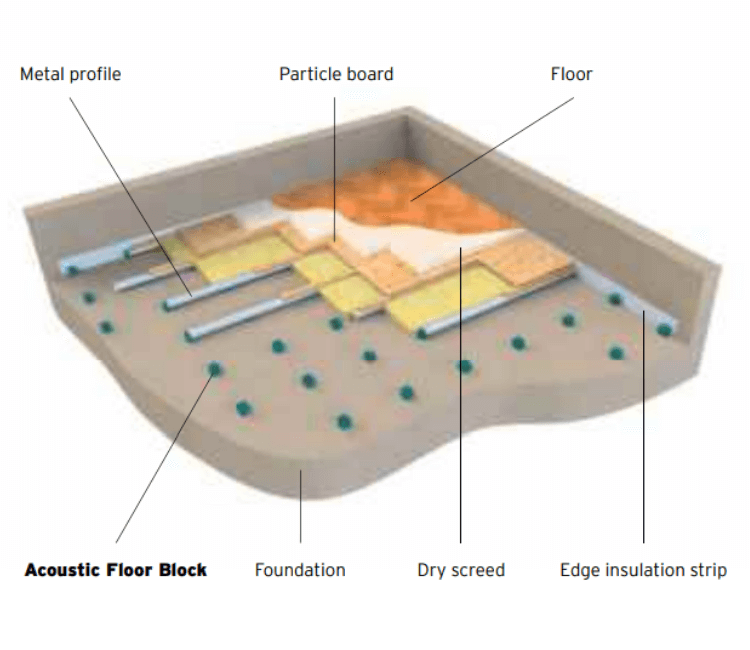

Getzner Acoustic Floor Blocks are state-of-the-art elastomer point bearings made from the specialized Sylomer® material. Designed for floating floors under both dry and wet screeds, the AFB product line excels in meeting high acoustic requirements, particularly at low frequencies. By achieving a low natural frequency ($f_0$ $\ge 6$ Hz), these blocks deliver excellent impact sound insulation and significantly minimise sound transmission through the structure.

The blocks offer an impressive impact sound reduction ($\Delta L_w$) of 31 dB with dry screed and 38 dB with wet screed. They are 50 mm thick and exhibit outstanding resistance to shock and impact, minimal settlement behaviour, and exceptional long-term ageing resistance, ensuring the acoustic integrity of your structure for decades.

Variations and Load Range of Acoustic Floor Blocks

Gitco-sa.com supplies the complete range of Acoustic Floor Blocks, tailored to specific structural loads:

-

AFB 30:

- Load range up to 30 kg/m²

- Impact sound reduction with dry screed ∆Lw: 31 dB

- Impact sound reduction with wet screed ∆Lw: 38 dB

- Natural frequency f₀: ≥ 6 Hz

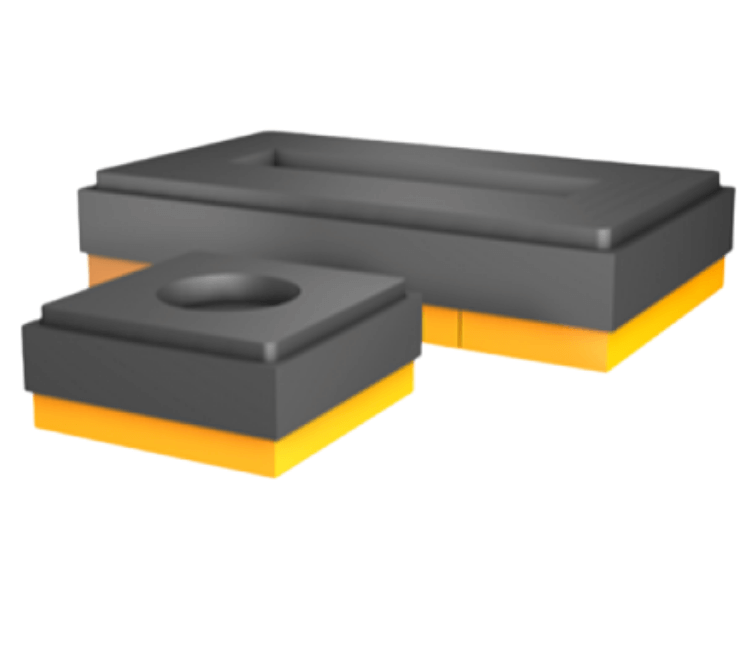

- Thickness: 50 mm

- Fire behaviour: Class E

-

AFB 60:

- Load range up to 60 kg/m²

- Impact sound reduction with dry screed ∆Lw: 31 dB

- Impact sound reduction with wet screed ∆Lw: 38 dB

- Natural frequency f₀: ≥ 6 Hz

- Thickness: 50 mm

- Fire behaviour: Class E

-

AFB 110:

- Load range up to 110 kg/m²

- Impact sound reduction with dry screed ∆Lw: 31 dB

- Impact sound reduction with wet screed ∆Lw: 38 dB

- Natural frequency f₀: ≥ 6 Hz

- Thickness: 50 mm

- Fire behaviour: Class E

-

AFB 160:

- Load range up to 160 kg/m²

- Impact sound reduction with dry screed ∆Lw: 31 dB

- Impact sound reduction with wet screed ∆Lw: 38 dB

- Natural frequency f₀: ≥ 6 Hz

- Thickness: 50 mm

- Fire behaviour: Class E

Key Applications of Acoustic Floor Blocks

-

Professional Audio Spaces: Indispensable in recording studios, sound booths, and concert halls for isolating low-frequency vibrations.

-

Entertainment Venues: Used in cinemas and stage construction to prevent floor vibrations from interfering with audio quality.

-

Noise-Sensitive Buildings: Creating high-performance floating floors in gyms, mechanical rooms, residential towers, and commercial spaces.

Gitco-sa.com is your reliable partner, providing a complete range of construction products. We offer the Lowest prices and other budget-friendly insulation options in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about Acoustic Floor Blocks:

- What are Acoustic Floor Blocks?

Acoustic Floor Blocks (AFBs) are prefabricated elements made from high-performance elastic materials (elastomers) like Sylomer or Sylodyn designed to isolate the floor slab from the rest of the structure, creating a “floating floor” system - What is the primary material used in Getzner Acoustic Floor Blocks?

They are typically made from Sylomer or Sylodyn, which are high-tech polyurethane elastomers developed by Getzner. - What is the difference between Sylomer and Sylodyn?

Sylomer is designed for elastic mounting and high damping, typically used for passive vibration isolation in a wide range of applications. Sylodyn is a more highly resilient material, often used for dynamic applications where high precision and long-term stability under dynamic load are required. - How do these materials provide acoustic isolation?

The highly elastic and resilient properties of the material absorb the kinetic energy from impacts or vibrations, effectively damping and interrupting the transmission path of structure-borne sound between the floor slab and the building structure. - How are the blocks typically constructed?

The elastic material (Sylomer/Sylodyn) is often pre-bonded to a metal or non-metallic plate (e.g., steel or aluminum) to facilitate easy installation and robust load transfer. - What type of noise do Acoustic Floor Blocks address?

They primarily address impact sound (e.g., footsteps, dropped objects) and structure-borne vibration (e.g., machinery, trains, traffic noise). - What is the main benefit of using AFBs over traditional resilient layers?AFBs provide superior long-term performance and maintain their specified elasticity and load-bearing capacity over decades, unlike some traditional materials that may creep or lose resilience over time.

- What is the typical reduction in noise achieved with these blocks?

The performance depends on the specific product and floor design (mass, thickness), but a properly designed floating floor using AFBs can achieve significant improvements in Impact Sound Reduction ($\Delta L_w$) often exceeding 25 dB. - Are they fire-resistant?

While the elastomers themselves may not be non-combustible, their use is within the floor structure, and the overall floating floor system, including concrete and fire barriers, must meet local fire safety codes. - Do they have any thermal insulation properties?

Their primary function is acoustic and vibration isolation. While elastomers have some inherent thermal resistance, they are not primarily designed or rated as thermal insulators. - Where are Acoustic Floor Blocks typically used?

They are essential in noise-sensitive areas such as:-

Concert halls and recording studios

-

Residential buildings (especially between floors)

-

Hotels and hospitals

-

Buildings near railways, highways, or heavy machinery

-

Gyms and technical equipment rooms

-

- What is a “floating floor” system?

A floating floor is a construction where the finished floor slab is isolated from the main structural slab and walls using an elastic layer (the Acoustic Floor Blocks) to prevent the transmission of sound and vibration. - How are the blocks installed?

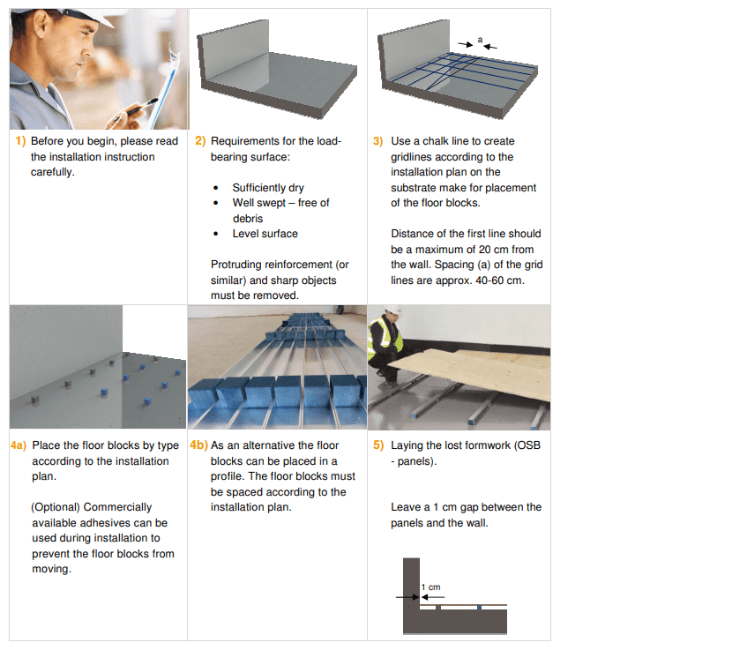

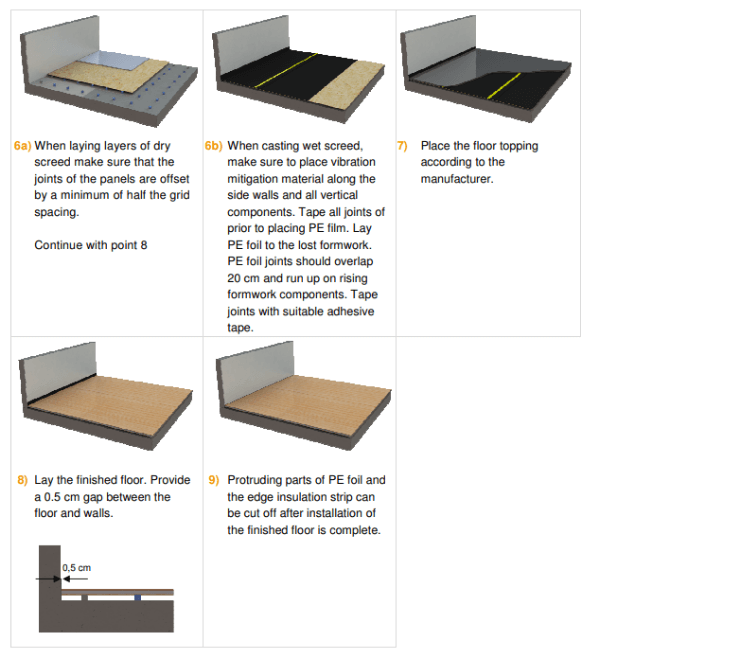

The blocks are strategically placed on the structural floor slab according to an engineered plan. The new, isolated concrete or screed floor slab is then poured directly on top of or around the blocks, which remain in place permanently. - Do they need to be replaced over time?

No. Getzner’s elastomers are engineered for an extremely long service life, often exceeding 50 years, maintaining their elastic properties without significant creep or degradation. - Can the blocks withstand heavy loads?

Yes, they are designed with specific load-bearing capacities (stiffness) tailored to the weight of the floor and any intended live loads (e.g., gym equipment or heavy machinery). - Is technical engineering support required for installation?

Yes, proper installation requires a structural and acoustic engineer to calculate the required stiffness, spacing, and number of blocks to achieve the target natural frequency and acoustic isolation. - What is the typical natural frequency achieved with these blocks?

AFBs are designed to achieve a very low natural frequency (often below 10 Hz). The lower the natural frequency, the better the isolation of low-frequency vibrations. - What kind of standards do they comply with?

They comply with international standards for acoustic and vibration isolation, including ISO 10140 for impact sound insulation and dynamic stiffness.

Additional information

| Applied on | Floor |

|---|

Brand

Getzner

Reviews

There are no reviews yet.