Getzner Isotop Sandwich Damping Pads: Planar Vibration Isolation

Getzner Isotop® sandwich vibration damping pads offer highly effective, low-weight planar isolation by combining robust pressure plates with Sylomer® or Sylodyn® elastomers. Gitco-sa.com provides the complete range of these high quality, best isolation products across Saudi Arabia.

Description

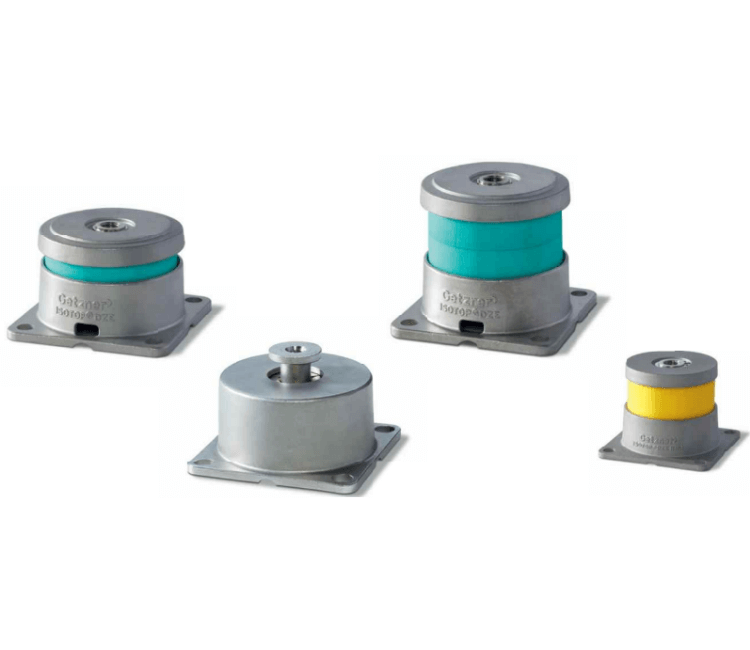

Getzner Isotop sandwich vibration damping pads are innovative isolators characterized by their unique construction: they consist of a high-strength pressure distribution plate (made from materials like galvanized steel or aluminum) bonded to a lightweight isolating layer made from the premium polyurethane elastomers, Sylomer® or Sylodyn®.

This “sandwich” structure achieves two critical functions simultaneously: high structural strength and exceptional acoustic insulation properties. The metal plate ensures the load (up to 3,480 kg per unit) is distributed evenly, maximizing the effectiveness of the elastomer underneath. This design is crucial for applications where sound control is as important as vibration damping. These pads boast simple installation, minimal maintenance, and are among the best isolation products for long-term industrial reliability.

The Complete Range of Isotop Sandwich Pads

Gitco-sa.com provides the complete range of Isotop® sandwich pads, offering specialized versions for standard equipment mounting and complex double-elastic bearings:

-

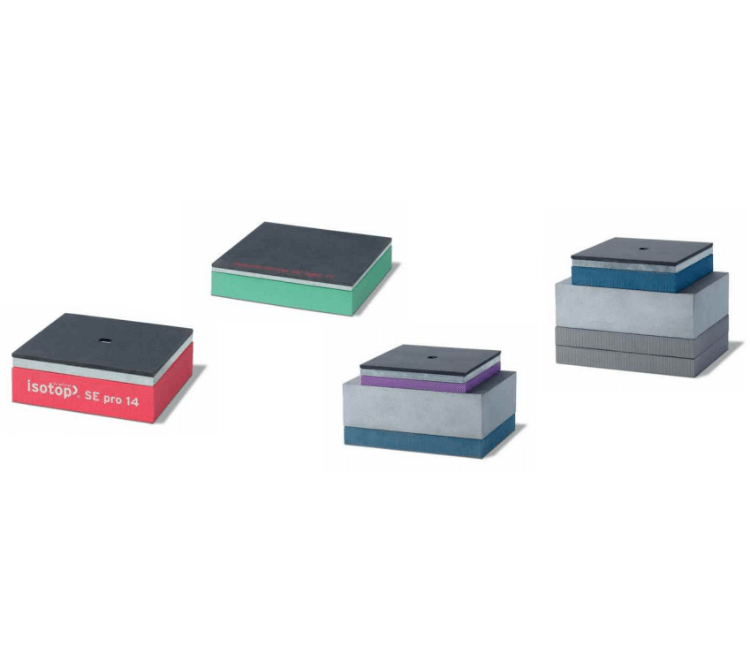

Isotop® SE light (Compact Isolation): A compact pad for medium loads, handling 63 kg to 930 kg. Features a thinner 25mm Sylomer® layer and a natural frequency from 10.8 Hz. Ideal for standard HVAC or machine mounting.

-

Isotop® SE pro (High-Performance Isolation): Designed for heavier loads between 90 kg and 2050 kg. Utilizes a 37.5mm Sylomer®/Sylodyn® layer to achieve a lower natural frequency from 7.5 Hz, providing increased damping.

-

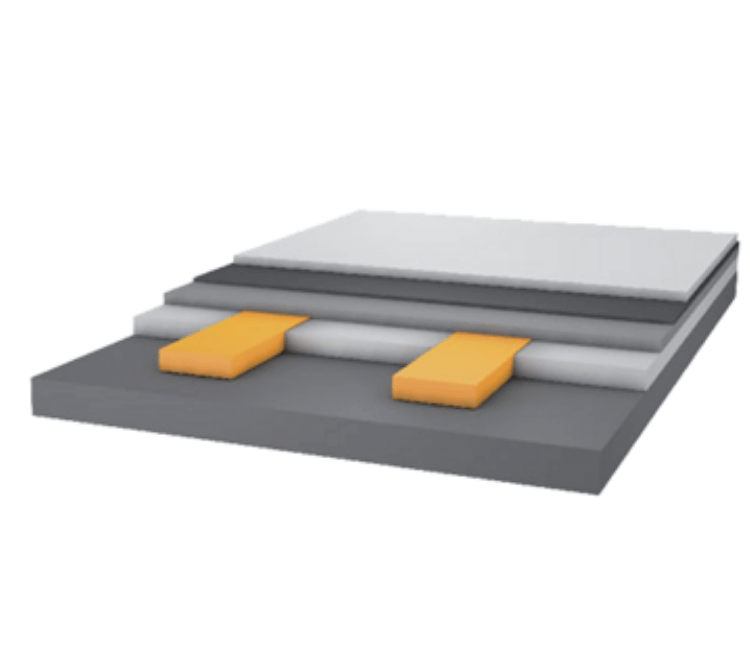

Isotop® SE-DE & SE-DE Elevator (Double Elastic Bearing): These specialized elements incorporate a heavy settling mass layer for double-elastic isolation, achieving the lowest natural frequencies (starting from 5.7 Hz) and handling loads up to 3,480 kg. They are essential for isolating extremely sensitive equipment or high-vibration sources.

Key Applications:

-

HVAC and Plant Equipment: Isolation of chillers, air-handling units (AHUs), cooling towers, and heavy machinery bases to reduce noise transmission to the structure.

-

Elevator and Escalator Isolation: The SE-DE Elevator variant provides superior protection for structures against the low-frequency vibrations generated by lifting systems, ensuring a quieter experience in high-rise buildings.

-

Sensitive Area Protection: Used as a planar barrier beneath test rigs, laboratory equipment, or control panels to protect them from external shocks and vibrations.

We guarantee that our Isotop® sandwich vibration damping pads are the best isolation products for high-performance acoustic and vibration control. Gitco-sa.com ensures the complete range of these high quality components is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about Isotop Sandwich Pads:

- What are Isotop® sandwich vibration-damping pads?They are innovative, multi-layered vibration isolators that combine an elastic polyurethane (PU) layer with rigid steel plates for uniform load distribution.

- What does the “sandwich” structure consist of?It typically consists of a steel pressure distribution plate (top and/or bottom) and a central isolating layer made from an elastomer, such as Sylomer® or Sylodyn®, often with an anti-slip mat on the bearing surface.

- What is the role of the steel plate in the sandwich?The steel plate provides high structural stability and ensures that the machine’s load is distributed evenly across the entire surface of the elastic layer, which is crucial for maximizing performance.

- What Getzner materials are used for the isolating layer?The isolating layer is typically made from Sylomer® (mixed-cell polyurethane elastomer) or Sylodyn® (closed-cell polyurethane elastomer), chosen based on the required load range and natural frequency.

- What feature allows the pads to be installed without screwing them down?Many models, such as the SE light and SE pro, are equipped with an integrated Sylomer® anti-slip mat on the top or bottom surface, which prevents the machine from shifting.

- What is the primary technical benefit of using these pads?They achieve a low natural frequency (fo), which is essential for isolating low-frequency vibrations (e.g., from slow-running fans or heavy equipment).

- What is the minimum natural frequency achieved by the standard SE pro model?The Isotop® SE pro model can achieve a low natural frequency starting from approximately 7.5 Hz.

- What is the typical load range for the Isotop® SE pro model?The SE pro model is designed for a medium to heavy load range, supporting up to approximately 2,050 kg per pad.

- What is the load range for the more compact Isotop® SE light model?The SE light model is suitable for lighter applications, with a load range up to approximately 930 kg per pad.

- What is the significance of the Isotop® SE-DE variant?The SE-DE (Double-Elastic) variant incorporates a heavy settling mass between two elastic layers, achieving an even lower natural frequency, starting from approximately 5.7Hz, ideal for highly sensitive isolation.

- Where are sandwich damping pads typically installed?They are used as machine mountings for equipment like fans, pumps, HVAC units, compressors, and generators, particularly in building services and industrial plants.

- Are the pads suitable for use on rooftops?Yes, their high structural stability, corrosion protection (often hot-dip galvanised), and damping properties make them ideal for rooftop installations of technical building equipment.

- Do the pads come with integrated connection points?Many models, like the Isotop® SE pro, include an M12 internal thread connection to allow the machinery to be securely bolted to the pad if required.

- How do the pads contribute to reduced operating costs?By reducing vibrations, they extend the service life and reduce the maintenance requirements for the mounted machinery, leading to lower operating costs.

- Are the pads designed to accommodate different machine frame widths?Yes, the sandwich design, which integrates the steel plate, makes them suitable for use with a wide range of different machine frame widths without needing to cut or custom-fit strip bearings.

- What is the overall installation height of the most compact version?The Isotop® SE light model has a low overall installation height, typically around 33 mm, making it suitable for spaces with low clearance.

- What is the specified permissible temperature range?The pads are certified for reliable use within a broad permissible temperature range of -30 °C to +70 °C.

- Are the sandwich pads resistant to environmental factors?Yes, the materials are highly durable, resistant to wear, aging, rot, and common oils and chemicals.

- Is there a tool to help engineers select the correct pad?Yes, Getzner provides specialized software, such as EquipCalc, which allows engineers to input machine weight and frequency to quickly determine the most suitable Isotop® pad type.

Brand

Getzner

Reviews

There are no reviews yet.