Getzner Steel Reinforced Elastomeric Bearings: High Load Isolation

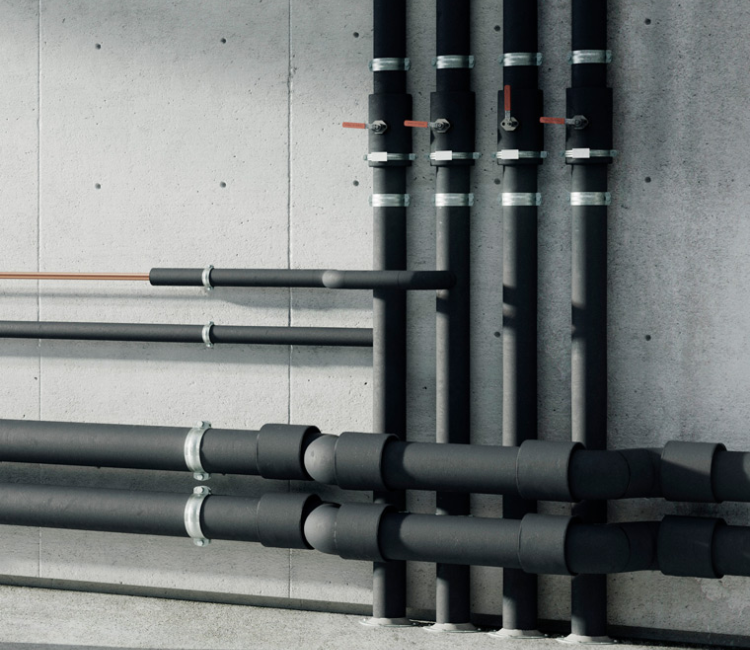

Getzner Steel Reinforced elastomeric bearings combine high-performance polyurethane with steel layers for superior load absorption in compact spaces. Offering a high quality solution for building vibration isolation, Gitco-sa.com supplies the complete range of the best isolation products across Saudi Arabia.

Description

Getzner Steel Reinforced elastomeric bearings are advanced construction elements engineered to meet the highest demands for load-bearing capacity and vibration isolation in structurally critical areas. This innovative design integrates high-performance polyurethane materials (such as Sylomer® or Sylodyn®) with integrated steel intermediate layers.

This reinforcement allows the bearings to absorb highly concentrated loads within the smallest possible footprint. They are specifically developed for situations where a limited support surface area meets high structural requirements, making them economical by reducing the need for complex structural adjustments. The bearings provide reliable dynamic isolation, achieving an optimal tuning frequency range of 6-12 Hz to protect buildings from external shocks and vibrations.

Variations and Structural Applications of Steel Reinforced Elastomeric Bearings:

Gitco-sa.com offers the complete range of Steel Reinforced elastomeric bearings for diverse structural needs:

-

Point Bearing on Supports: The compact design is perfect for transferring highly concentrated single loads under columns and critical supports, maximizing load capacity in limited space.

-

Row Storage on Wall Panels: Used in an inline arrangement for uniform load distribution under wall panels and suitable for transferring necessary horizontal loads.

-

Storage in Multi-storey Buildings: Employed in central load transfer areas or under façade supports, where their high load-bearing reserves simplify planning and design.

These steel reinforced elastomeric bearings represent the best isolation products available, ensuring both high quality structural stability and superior acoustic performance.

Key Applications of Steel Reinforced Elastomeric Bearings:

-

High-Rise and Multi-storey Buildings: Essential for high-load transfer areas, allowing for compact structural design while minimizing vibration transmission between floors.

-

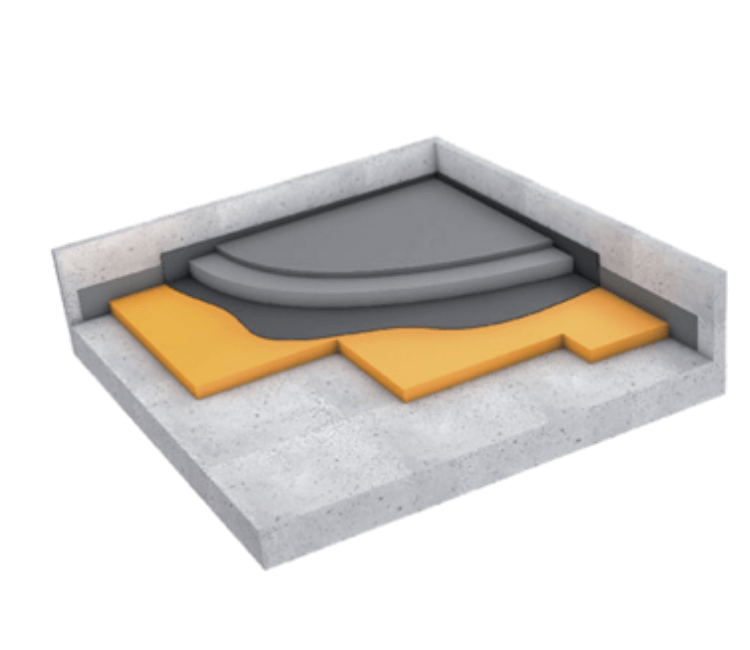

Building Decoupling (Base Isolation): Creating isolation layers under key structural supports to decouple the entire building from railway or road traffic vibration.

-

Façade Supports: Providing both load transfer and vibration dampening for heavy, dynamically loaded façade elements.

Gitco-sa.com is your reliable partner, supplying this complete range of high quality Getzner isolation solutions in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about Steel Reinforced elastomeric bearings:

-

What are Steel Reinforced Elastomeric Bearings?

They are specialized structural components composed of alternating layers of elastomer (rubber or polyurethane) and steel plates, which are fused together during the manufacturing process (vulcanization or bonding). -

What is the core purpose of the steel reinforcement?

The internal steel plates are essential for increasing the vertical compressive stiffness of the bearing. They prevent the elastomer from significantly bulging laterally under high compressive loads, allowing the bearing to support massive weights. -

What role does the elastomer play?

The elastic elastomer layers accommodate the horizontal shear movement (translation) and rotation of the structural element (like a beam or column), effectively transferring loads while remaining flexible. -

How do these bearings achieve movement and isolation?

They function as a spring, allowing the structure to compress vertically and move horizontally due to the internal deformation of the elastomer layers, which absorbs and dissipates kinetic energy from vibrations. -

Why use Getzner’s polyurethane elastomers instead of standard rubber/neoprene?

Getzner’s proprietary Sylomer® or Sylodyn® elastomers offer superior performance in terms of long-term stability, low creep tendency, and high damping characteristics, ensuring the bearing maintains its specified performance for decades. -

Where are these reinforced bearings typically used?

They are commonly used in bridges (under prefabricated concrete or steel beams), under heavy industrial machinery, and in structural base isolation for buildings to isolate against rail or traffic vibrations. -

What structural movements do they accommodate?

They accommodate vertical compression (static load), horizontal shear movement (thermal expansion/contraction, ground movement), and rotational movement of the superstructure. -

What are the key advantages over traditional rigid bearings?

The main advantages are low maintenance, long service life, easy installation, and their ability to uniformly transfer horizontal and vertical loads while accommodating movement. -

Do they also provide seismic isolation?

Yes, specialized types of laminated elastomeric bearings are used as seismic isolators to dissipate earthquake energy and protect the structure from damaging ground movements. -

How does the steel protect the elastomer?

The internal steel plates are completely encapsulated or vulcanized within the elastomer layers, which protects the steel from corrosion and other external environmental agents, contributing to the product’s long lifespan. -

What dictates the vertical stiffness of the bearing?

The vertical stiffness is governed by the number and thickness of the internal steel reinforcing plates and the thickness of the elastomer layers. More steel plates (and thinner elastomer layers) increase the vertical stiffness. -

What are the typical design standards these bearings comply with?

They are designed and manufactured to comply with international standards, such as the European CE EN 1337 series for structural bearings. -

What is the typical maximum vertical load capacity?

High-quality reinforced elastomeric bearings can handle extremely high vertical loads, with some types supporting compression loads typically up to 15 MPa (MegaPascals) or higher. -

How are different movement requirements accommodated?

For large movements, the bearings can be equipped with a sliding surface, such as a PTFE (Teflon) sheet bonded to the elastomer or steel, which allows for horizontal sliding with a low coefficient of friction. -

What is the expected service life?

Due to the protective elastomer covering and the highly durable materials, these bearings are designed for a long, maintenance-free service life, often exceeding 50 years. -

Is installation difficult?

No, reinforced elastomeric bearings are typically supplied as a pre-assembled unit ready for installation, making them a cost-effective and relatively simple solution for supporting beams. -

What are the common configurations (Types B, C, D)?

-

Type B: Laminated, fully covered with elastomer, with internal steel plates.

-

Type C: Features external steel plates on one or both surfaces, often used for anchoring or slip protection.

-

Type D/E: Laminated bearings equipped with an added PTFE sliding layer for accommodating large horizontal translations.

-

-

Can they be anchored to the structure?

Yes, certain types (like Type C) include outer steel plates with provisions for dowels, threaded rods, or bolts to anchor the bearing and provide slip protection under tensile or shear forces. -

What is a “Plain Pad” (Non-reinforced) bearing?

A plain pad bearing (Type F) consists only of a single block of elastomer without steel reinforcement. They are used for lower loads and where the requirements for load distribution and controlled deflection are less stringent.

Brand

Getzner

Reviews

There are no reviews yet.