Getzner Isotop Anti-Vibration Spring Mounts: Machine Isolation

Getzner Isotop® anti-vibration spring mounts provide superior machine isolation for floor-standing equipment using low natural frequency steel springs. Gitco-sa.com offers the complete range of these high quality, best isolation products across Saudi Arabia.

Description

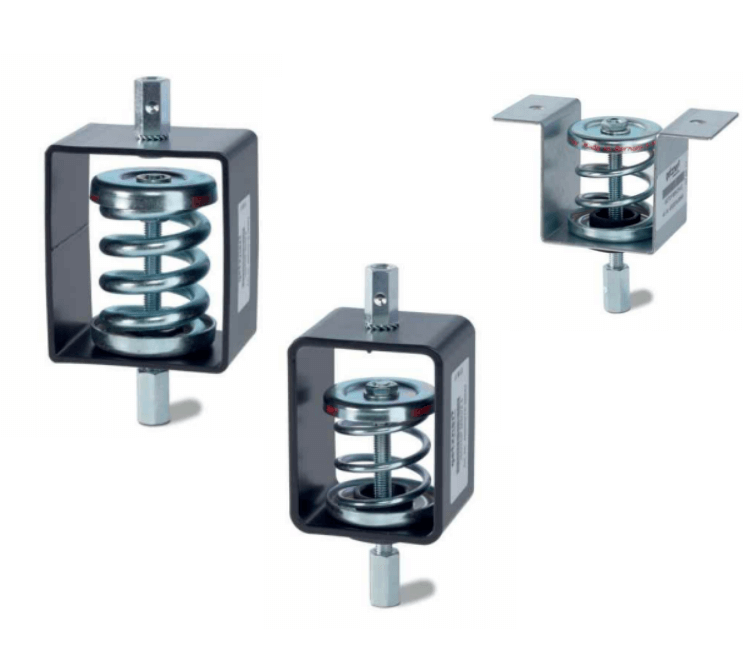

Getzner Isotop® anti-vibration spring mounts are the definitive solution for the active and passive vibration isolation of machines and industrial equipment. Utilizing high-performance steel springs within a compact, durable housing, these mounts are specifically designed to absorb shocks and dampen vibrations in the vertical direction, significantly improving the performance and reliability of the isolated devices.

The key technical advantage is the low natural frequency (starting from $3.2 \text{ Hz}$), which delivers the highest possible levels of vibration isolation. This makes them exceptionally effective for machines, such as industrial fans, compressors, or generators, that operate with low-frequency disturbing forces. The robust construction, featuring corrosion protection like electro-galvanization or cathodic dip-painting, ensures long-term high quality and longevity, even in demanding industrial environments.

The Complete Isotop Spring Mount Range

Gitco-sa.com provides the complete range of Isotop® anti-vibration spring mounts, offering scalable solutions for light to extremely heavy machinery:

-

Isotop® MSN (Standard): Designed for lighter applications (e.g., small fans, pumps) with load ranges between 3 kg and 90 kg and a natural frequency from $3.5 \text{ Hz}$.

-

Isotop® SD (Heavy-Duty): Ideal for medium to heavy equipment with load ranges between 20 kg and 525 kg and a low natural frequency from $3.2 \text{ Hz}$. Features a consistent overall height for maximum installation flexibility.

-

Block Elements (Isotop® MSN BL & SD BL): Composed of multiple individual spring elements (e.g., 2 or 4 units) combined into a single block. These units handle massive loads, ranging from 117 kg up to 4730 kg, ensuring effective isolation for the heaviest industrial machines.

Key Applications of Isotop Spring Mount

-

Machine and Plant Engineering: Isolating manufacturing equipment, presses, and control units from building structure to protect sensitive processes and adjacent spaces.

-

HVAC Systems: Used beneath floor-standing chillers, industrial fans, and pumping sets to prevent mechanical vibration from entering the structure.

-

Power Generation: Isolating generator sets and large transformers to comply with noise and vibration standards in urban or industrial zones.

-

Automotive Industry: Providing vibration damping for test rigs and specialized machinery.

We guarantee that our Isotop® anti-vibration spring mounts are the best isolation products, delivering superior high quality and performance. Gitco-sa.com ensures the complete range is available for delivery and support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about Isotop Spring Mount:

- What are Getzner Isotop® anti-vibration spring mounts?They are highly engineered machine mounts consisting primarily of steel springs and metal elements, often combined with Getzner’s polyurethane (PU) materials for enhanced performance.

- What is the main function of the spring mounts?Their main function is to provide efficient vibration isolation and shock absorption for machines and equipment, preventing the transmission of unwanted vibrations and structure-borne noise.

- What is the core isolation component?The core component is the steel spring isolator, which provides the necessary deflection to achieve a very low natural frequency.

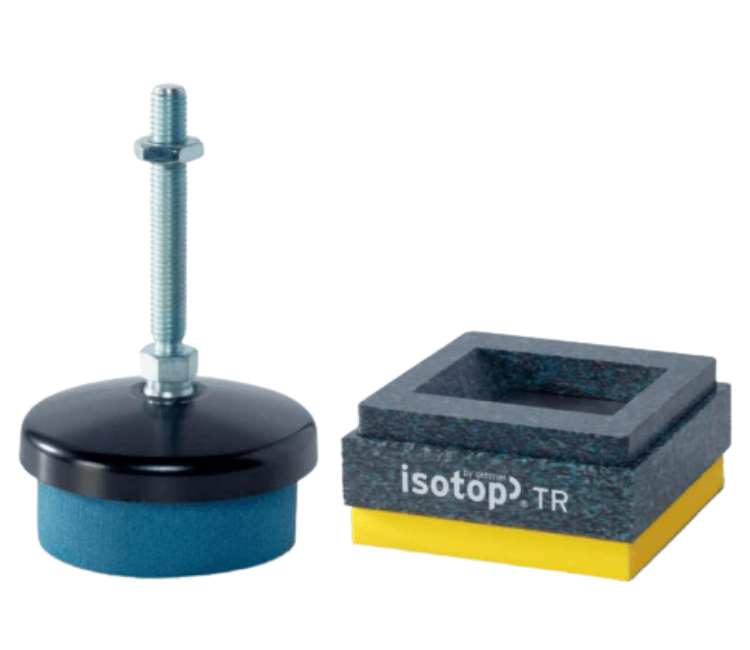

- Are the Sylomer® or Sylodyn® materials used in the spring mounts?Yes, these PU elastomers are often integrated into the mounts (e.g., as damper cores in the DSD/DMSN models or as anti-slip mats in the block elements) to enhance damping and stabilize the spring’s resonance.

- What type of machines are these mounts particularly suitable for?They are particularly suitable for machines and equipment with low excitation frequencies, such as fans, ventilators, compressors, cooling towers, and HVAC systems.

2. Performance and Acoustic Metrics

- What is the typical natural frequency achieved by the Isotop® mounts?The steel spring models achieve very low natural frequencies, typically starting from 7$3.2 \text{ Hz}$ to 8$3.5 \text{ Hz}$ for individual springs, ensuring excellent isolation of low-frequency disturbances.

- Why is a low natural frequency important for these applications?A low natural frequency is crucial because low-frequency vibrations travel further through a building structure and are often the source of the most disruptive structure-borne noise.

- What is the load range for the heavy-duty Isotop® SD series?The Isotop® SD series covers a high load range, typically between 20 kg and 525 kg per individual mount.

- What is the load range for the block elements (e.g., SD-BL)?The heavy-duty block elements (SD-BL), which combine multiple springs, can handle very high loads, ranging from approximately 14$690 \text{ kg}$ up to 15$4,730 \text{ kg}$ per block.

- How do the damper core variants (e.g., Isotop® DSD) differ?The damper core variants integrate a PU element inside the spring, improving shock pulse damping and stabilizing the spring to minimize unwanted lateral movement.

3. Applications and Installation

- In what major sectors are these spring mounts used?They are widely used in the Building Services (HVAC), industrial machinery, machine engineering, and power generation sectors.

- Are they suitable for outdoor installation (e.g., on rooftops)?Yes, the metal components are often electro-galvanised or cathodic dip-painted to provide a high level of corrosion protection, making them ideal for outdoor and rooftop installations.

- How do the Isotop® mounts simplify installation?They are designed to be easy and convenient to mount, often featuring internal threads or threaded rods so they can be screwed directly onto the machine or equipment frame.

- Do they provide height adjustment capability?Yes, accessories like the Isotop® NV (Height Adjustment) are available for certain models (SD/MSN) to allow for precise machine leveling and stability adjustment.

- Can the mounts be used for transformers?Yes, specialised versions like the Isotop® Transformer Pad TR, which uses Sylodyn®, are available for high-load applications like transformers with wheels.

4. Durability and Commerce

- Do the mounts have consistent overall heights within a product range?Yes, a key design feature is the consistent overall height across variants within the same product family (e.g., all Isotop® SD are 94mm high), which aids in system configuration and interchangeability.

- What is the permissible temperature range for the mounts?The permissible operating temperature range is wide, typically from -30 °C to +70 °C.

- What is the expected maintenance requirement?The robust design and durable PU/steel combination mean the Isotop® products are designed to be maintenance-free and provide reliable performance for decades.

- Is there a tool available to help select the right product?Yes, Getzner provides software tools like EquipCalc to help engineers quickly determine the most suitable Isotop® product based on machine weight, number of bearing points, and excitation frequency.

Brand

Getzner

Reviews

There are no reviews yet.