Pipe Section: Thermal & Acoustic Pipe Insulation

Pipe Section is a comprehensive thermal and acoustic insulation solution for both industrial and domestic pipes. Made from non-combustible rock wool, it offers superior heat retention, noise reduction, and a Euro Class A1 fire rating. Gitco-sa.com provides a complete range of pipe sections with competitive prices across Saudi Arabia, UAE, and Bahrain.

Description

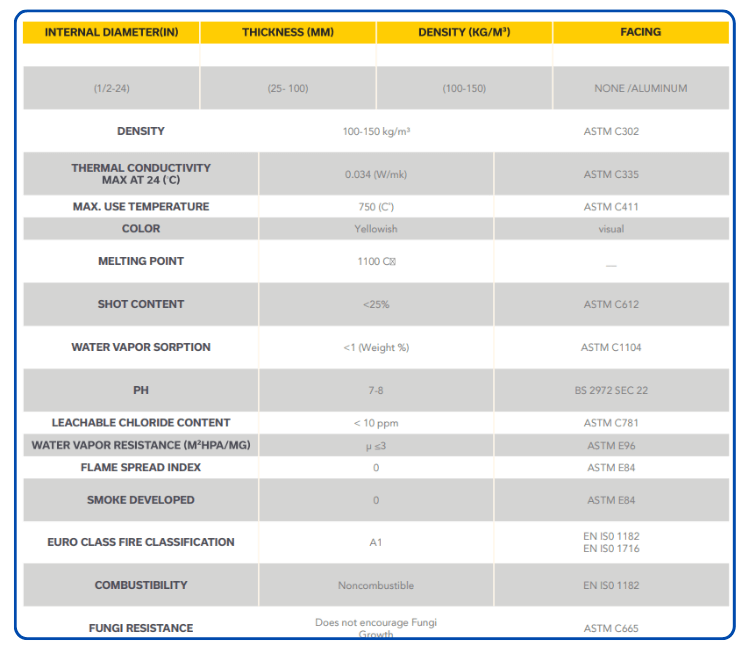

Rockwool Pipe Section is a pre-formed insulation made from molten basalt rocks spun into fine fibers and bonded with a thermosetting resin. This product is specifically designed to provide excellent thermal and acoustic performance for a wide variety of pipe systems. With a maximum thermal conductivity of 0.034 W/m.K at 24°C, it is highly effective at preventing heat loss in hot applications and heat gain in cold ones. Its non-combustible nature and Euro Class A1 fire classification ensure the highest level of fire safety.

The Pipe Section also excels at noise control, with its dense structure (100-150 kg/m³) helping to dampen sound and vibrations from fluid-carrying pipes. The material is non-corrosive, has a pH between 7 and 8, and does not encourage fungi growth, ensuring its durability and a long lifespan. Gitco-sa.com offers a complete range of Pipe Sections, with variations in internal diameter (from 1/2″ to 24″) and thickness (25 mm to 100 mm) to fit almost any pipe size. It is available unfaced or with an Aluminum facing to suit different installation requirements.

Key Applications of Rockwool Pipe Section:

- Industrial Piping: Insulating high-temperature pipes in refineries, power plants, and chemical factories to conserve energy and provide personnel protection.

- HVAC and Plumbing: Used on hot and cold water pipes, heating lines, and refrigeration systems to prevent heat transfer and condensation.

- Marine Applications: Provides thermal and acoustic insulation for piping systems on ships and offshore platforms.

- Noise Control: Reduces noise from pipe-bound fluids in commercial buildings, hospitals, and residential complexes.

Our Rockwool Pipe Section prices are the Lowest for Pipe Section products, and we provide budget-friendly Pipe Section in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia, UAE, and Bahrain, with a complete range to meet all your project needs.

Know more about Pipe Section:

1. Product & Composition

- What are Pipe Sections?

Pipe Sections are rigid, pre-formed insulation cylinders made from materials like rock wool or fiberglass. They are manufactured to fit specific pipe diameters, making installation quick and efficient. - What is the primary material used for pipe sections?

The most common material is rock wool (or stone wool). It’s made by melting basalt rock and spinning it into fibers, which are then molded into a cylindrical shape. - What is the typical density of rock wool pipe sections?

The density is relatively high, often between 120 kg/m³ to 160 kg/m³, which gives the product its excellent structural integrity, acoustic performance, and thermal properties. - Are they fire-resistant?

Yes, rock wool is inherently non-combustible and has a melting point exceeding 1000°C. Pipe sections are typically rated Euroclass A1, the highest fire safety classification. - How do they provide thermal insulation?

The fibrous structure of the rock wool traps air within the material, creating a thermal barrier that significantly reduces heat loss from hot pipes and prevents heat gain on cold pipes. - What is their thermal conductivity (k-value)?

They have a very low thermal conductivity, usually in the range of 0.034 to 0.038 W/m·K, making them highly efficient at maintaining temperature. - Do they also provide acoustic insulation?

Yes. The high-density, fibrous material is excellent for sound absorption, which helps to muffle noise from fluid flow, mechanical vibrations, or noise breakout from the pipes. - Are they resistant to moisture and water?

Yes, rock wool is naturally hydrophobic. It repels water and does not absorb moisture, which is critical for preventing corrosion under insulation (CUI) and inhibiting mold and fungi growth.

2. Applications & Benefits

- What types of pipes can be insulated with pipe sections?

They are suitable for a wide range of pipes, including hot and cold water pipes, steam pipes, HVAC lines, industrial process pipes, and cryogenic applications. - What is the main advantage of using pre-formed pipe sections over other insulation types?

Their snap-on, pre-formed design makes installation extremely fast and easy, reducing labor costs and ensuring a consistent, tight fit with minimal gaps, which would otherwise lead to thermal bridging. - Do they come with different facings?

Yes, they are often supplied with or without facings. Common facings include a reinforced aluminum foil which acts as a vapor barrier for cold applications and protects the insulation. - How do they prevent condensation on pipes?

On cold pipes, the insulation’s vapor barrier facing and its thickness prevent the pipe surface temperature from dropping below the dew point, which stops condensation from forming. - Are they suitable for both indoor and outdoor use?

Yes. For outdoor use, the pipe sections must be protected by an additional weatherproof cladding like metal or a polymeric jacket to shield them from UV radiation and rain. - Do they contribute to a building’s energy efficiency?

Yes, by maintaining the temperature of the fluid within the pipes, they significantly reduce the energy required for heating and cooling, which leads to substantial cost savings and a lower carbon footprint. - Are they considered a sustainable material?

Yes. They are made from a natural and abundant resource (volcanic rock), and their long service life and recyclability contribute to a more sustainable building.

3. Standards & Sourcing

- What international standards do these products comply with?

High-quality pipe sections are manufactured to comply with international standards such as ASTM C 547 and EN 13472, ensuring their performance and safety. - What is the significance of the ASTM C547 standard?

This standard specifies the requirements for mineral fiber pipe insulation, ensuring the product is suitable for its intended temperature range and application. - Can they be used to insulate pipe elbows and fittings?

Yes, while they are straight sections, they can be cut into segments to fit around elbows and other fittings. These segments are then secured with banding and sealed to ensure a continuous thermal and acoustic envelope. - Where can I purchase and get technical data on these products in the Middle East?

A specialized supplier like Gitco-sa.com is a primary source for these products in the UAE and Saudi Arabia. They provide access to technical data sheets, certifications, and expert advice for specific project requirements.

Reviews

There are no reviews yet.