Rockwool Acoustic Panels: Superior Sound Insulation

Rockwool Acoustic Panels are rigid, non-combustible insulation slabs designed for superior sound absorption and thermal performance. Gitco-sa.com provides a complete range of these panels, with the lowest prices for Cavity Panels and budget-friendly Loose Wool in Saudi Arabia, UAE, and Bahrain.

Description

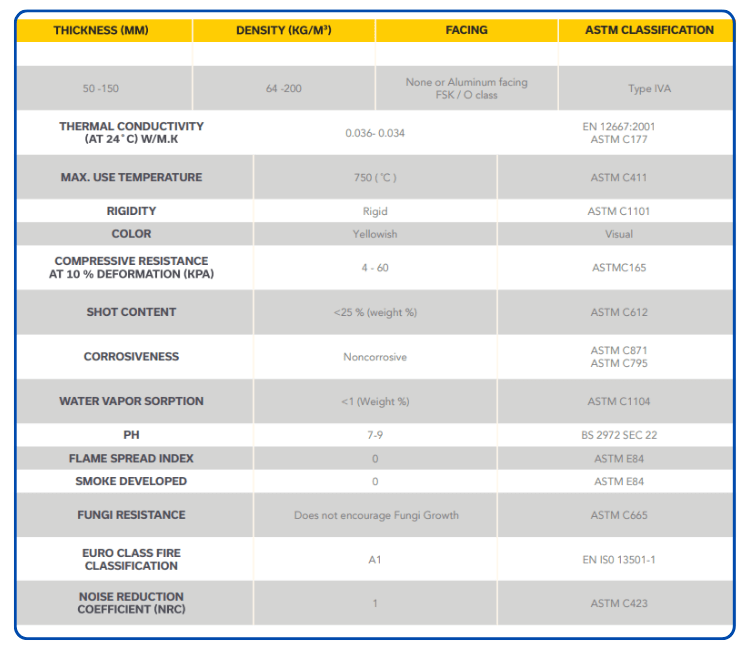

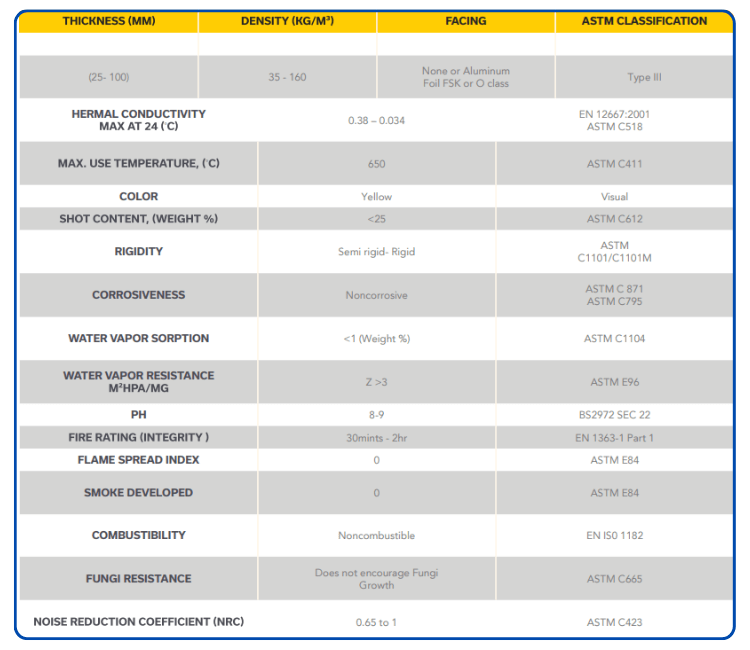

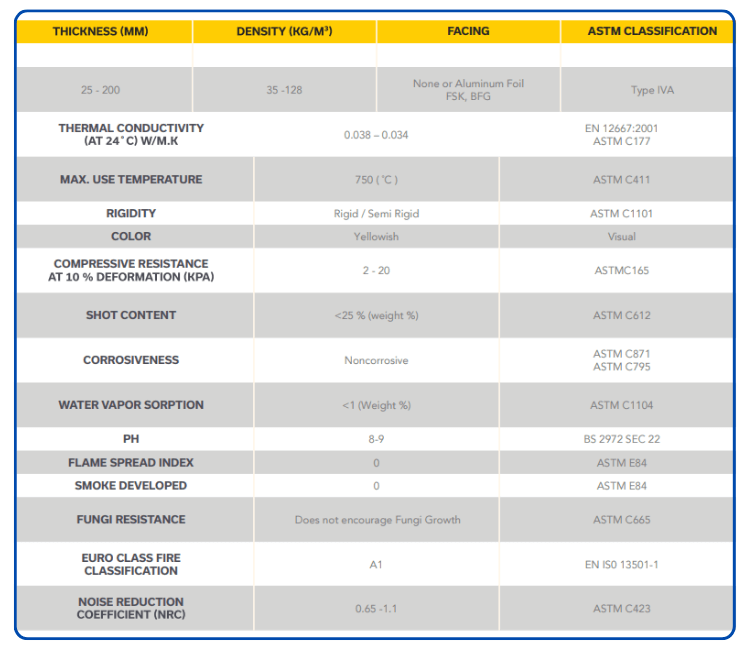

Rockwool Acoustic Panels are high-performance, rigid insulation slabs meticulously crafted from molten basalt rocks. The fibers are bonded with a thermosetting binder to form durable panels that offer exceptional sound absorption and thermal resistance. These panels are engineered to meet the stringent requirements of ASTM C612, making them an ideal choice for a wide range of applications where noise control and fire safety are critical. They are classified with an A1 Euro Class Fire Classification, the highest possible rating for non-combustible materials, ensuring they will not contribute to the spread of fire.

Acoustically, these panels are highly effective, with a Noise Reduction Coefficient (NRC) ranging from 0.65 to 1.1. This makes them perfect for significantly reducing sound transmission and echo, creating a quieter, more comfortable environment. The panels have a thermal conductivity between 0.038 and 0.034 W/m.K at 24°C, providing excellent thermal insulation. They are also non-corrosive, have a pH of 8-9, and do not encourage the growth of fungi. Gitco-sa.com offers a complete range of Saudi Rockwool Acoustic Panels with variations in thickness (25-200 mm), densities (35-128 kg/m³), and facings (None, Black Fiberglass (BFG), or WOBFG) to suit diverse project requirements.

Key Applications of Rockwool Acoustic Panels:

- Wall and Partition Systems: Enhance the Sound Transmission Class (STC) for improved privacy and reduced noise transfer between rooms.

- Ceiling Systems: Used to absorb sound and reduce reverberation in large spaces like offices, auditoriums, and conference halls.

- Studios and Theaters: Ideal for controlling echo and optimizing sound quality for clarity in recording studios and performance venues.

- Industrial and Commercial Buildings: Provides thermal and acoustic insulation in offices, schools, hospitals, and other spaces where comfort is key.

Our Acoustic Panels are available at the most competitive prices, and we are proud to offer the lowest prices for our Cavity Panels and budget-friendly Loose Wool in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia, UAE, and Bahrain, with a complete range to meet all your needs.

Know More about Rockwool acoustic panel:

1. What is a Rockwool acoustic panel?

Acoustic panels made from rock wool fibers are dense, semi-rigid, or rigid slabs designed to absorb sound waves and reduce noise. They are often used within wall cavities or as visible wall/ceiling panels to improve a room’s acoustics.

2. How do Rockwool acoustic panels work for sound absorption?

Their open, fibrous, and high-density structure traps sound waves, dissipating their energy as a small amount of heat. This process significantly reduces echoes and reverberation within a room.

3. What is a good NRC rating for an acoustic panel?

A good NRC (Noise Reduction Coefficient) is typically considered to be 0.70 or higher. Rockwool acoustic panels can achieve a high NRC, often between 0.70 and 1.0, making them highly effective.

4. What is the difference between sound absorption and sound insulation?

Sound absorption reduces noise within a space by minimizing echoes, while sound insulation prevents sound from passing through a building element, like a wall or floor. Rockwool panels are excellent at both.

5. What are the key benefits of using Rockwool acoustic panels?

The main benefits are exceptional sound absorption, high fire resistance, excellent thermal insulation, durability, and resistance to mold, fungi, and moisture.

6. Are Rockwool acoustic panels fire-resistant?

Yes, they are non-combustible with a Euroclass A1 fire rating, the highest possible. They have a melting point of over 1000°C and do not contribute to flame spread or produce toxic smoke in a fire.

7. What is the typical density of these panels?

The density for acoustic performance typically ranges from 60 to 100 kg/m³. Higher densities are often used for applications that require better low-frequency sound absorption.

8. How do Rockwool acoustic panels compare to fiberglass?

Rockwool generally has a higher density, which provides better sound absorption, especially for low-frequency sounds. It is also more fire-resistant and holds its shape better than standard fiberglass insulation.

9. Are they safe to use in residential and commercial buildings?

Yes, they are considered safe, non-toxic, and free from asbestos. High-quality products are also certified for low VOC (Volatile Organic Compound) emissions to ensure healthy indoor air quality.

10. How are Rockwool acoustic panels installed?

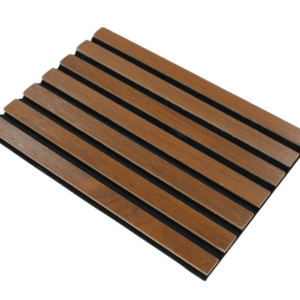

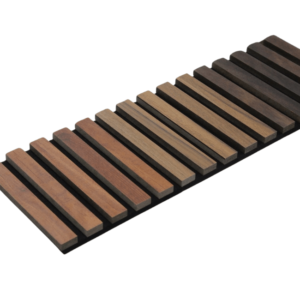

They can be friction-fitted into wall cavities between studs or mounted directly onto walls or ceilings using adhesives or mechanical fasteners. For a finished look, they are often covered with a decorative fabric or facing.

11. What types of spaces are they used in?

They are used in a wide range of spaces, including recording studios, home theaters, conference rooms, schools, hospitals, commercial offices, and industrial facilities.

12. Can they be faced with other materials?

Yes, they can be faced with a variety of materials, such as black fiberglass veil (BFG), decorative fabrics, or woven fiberglass fabric, to improve aesthetics and provide additional protection.

13. Do they have thermal insulation properties?

Yes, due to their fibrous structure, they have excellent thermal conductivity ratings, making them effective for both thermal and acoustic insulation.

14. What is the typical size and thickness of the panels?

Standard sizes are often 0.6m x 1.2m, with a range of thicknesses from 25 mm to 100 mm. Thicker panels generally offer better overall acoustic performance.

15. Are they resistant to moisture and mold?

Yes, rock wool is naturally hydrophobic and does not absorb water. This property makes it resistant to moisture-related issues like mold, fungi, and rot.

16. What is the cost of Rockwool acoustic panels?

The cost varies widely based on density, thickness, and facing options. They are generally priced competitively with other high-performance acoustic materials.

17. Are these products considered sustainable or environmentally friendly?

Yes, rock wool is made from an abundant natural resource (volcanic rock), and its use in buildings significantly reduces energy consumption for heating and cooling, which lowers the building’s overall carbon footprint.

18. Do they help with green building certifications like LEED?

Yes, products with a high recycled content and low VOC emissions can contribute to earning credits for LEED (Leadership in Energy and Environmental Design) and other green building certifications.

19. Where can one find technical data on these panels in the UAE and Saudi Arabia?

A specialized supplier like Gitco-sa.com will provide access to the technical data sheets, certifications (e.g., ASTM C-612), and professional advice needed for a project.

Reviews

There are no reviews yet.