Rockwool HD Board: High-Density Thermal Insulation

Rockwool HD Board is a premium, high-density rock wool board designed for optimal thermal and acoustic performance in demanding industrial and commercial applications. It is rigid, non-combustible, and offers excellent compressive strength. Gitco-sa.com provides a complete range of this product, with competitive prices across Saudi Arabia, the UAE, and Bahrain.

Description

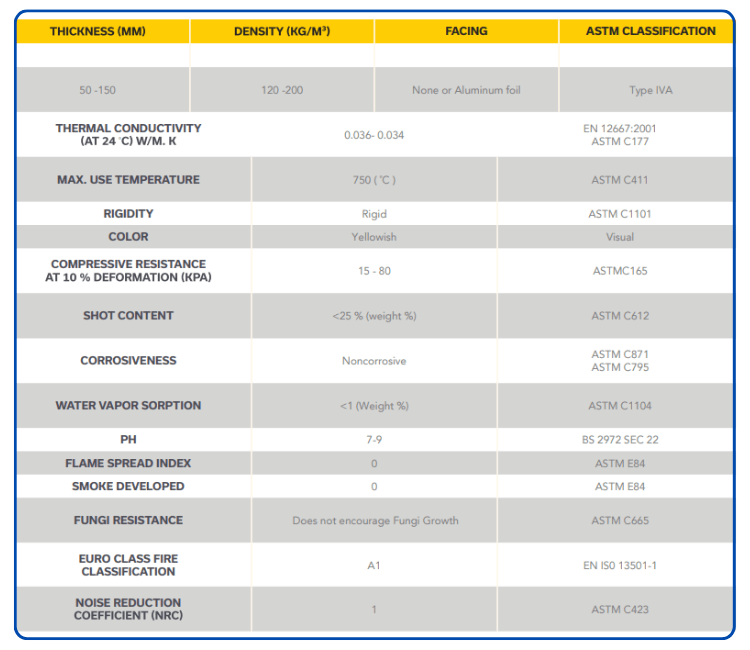

Saudi Rockwool HD Board is a high-density, rigid insulation slab produced from molten basalt rocks spun to fine fibers and bonded with a thermosetting binder. This material is engineered to provide a high level of thermal, fire-resistant, and acoustical properties, complying with ASTM C612 and EN 13162 requirements. It offers superior thermal conductivity, with a value ranging from 0.034 to 0.036 W/m.K at 24°C. The board is also highly effective for noise control, boasting a Noise Reduction Coefficient (NRC) of 1.

The HD Board is non-combustible and has the highest Euro Class A1 fire classification. It can withstand maximum use temperatures of up to 750°C and has a compressive resistance of 15-80 kPa at 10% deformation, making it highly durable for structural applications. The material is also non-corrosive and does not encourage fungi growth. Gitco-sa.com offers a complete range of HD Boards with various densities (120-200 kg/m³) and thicknesses (50-150 mm). It is available unfaced or with an Aluminum foil facing.

Key Applications of Rockwool HD Board:

- Industrial Equipment: Ideal for insulating high-temperature industrial equipment like boilers and ovens.

- Structural Insulation: Used in building structures, walls, and partitions where high compressive strength is required.

- Acoustic Control: Provides a robust solution for sound absorption in loud industrial and commercial environments.

- Roofing: Its high compressive resistance makes it suitable for use in roofing systems subjected to heavy loads.

Our Cavity Panels prices are the Lowest for Cavity Panels products, and we provide budget-friendly Loose Wool in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia, UAE, and Bahrain, with a complete range to meet all your project needs.

Know more about Rockwool HD Board:

1. What is Rockwool HD Board?

Rockwool HD Board is a rigid, high-density insulation board made from mineral wool fibers spun from molten basalt rock. The fibers are bonded with a thermosetting resin to form a strong, dimensionally stable slab.

2. What makes it “high-density”?

Its high density, typically ranging from 80 kg/m³ to over 150 kg/m³, gives it exceptional physical properties, particularly its ability to resist compression and maintain its shape under load.

3. What is the main benefit of high density?

The primary benefit is high compressive strength, which allows the board to be used in applications where the insulation must support a significant load, such as on roofs, floors, or behind heavy cladding systems.

4. What is the typical compressive strength of an HD Board?

Compressive strength can vary by product type and density, but it is generally at least 15 kPa and can be much higher, ensuring it won’t deform under pressure.

5. How does it perform as a thermal insulator?

It offers excellent thermal resistance. The fibrous structure traps air, creating a barrier that slows down heat transfer. Its thermal conductivity (k-value) is very low, often in the range of 0.034 to 0.039 W/mK.

6. Is it a good soundproofing material?

Yes, the high density and open-cell structure of the board make it a very effective sound absorber. It has a high Noise Reduction Coefficient (NRC), often exceeding 0.85, which helps to reduce noise transmission and control reverberation.

7. What is its fire rating?

Rockwool is inherently non-combustible. The HD Board has the highest fire safety classification, Euroclass A1, and a melting point exceeding 1000°C, providing excellent passive fire protection.

8. What are the key applications for HD Board?

Its applications are widespread and include:

- External Wall Insulation (EWI) and rainscreen facades.

- Roof insulation (flat roofs and pitched roofs).

- Floor insulation in residential and commercial buildings.

- Industrial applications such as vessels, tanks, and boilers.

- Fire-rated walls, partitions, and doors.

9. Is it resistant to moisture and water?

Yes, rock wool is naturally hydrophobic. It repels water and does not absorb moisture, which prevents a loss in thermal performance and inhibits the growth of mold and fungi.

10. Does it contain harmful chemicals like asbestos?

No, it is asbestos-free and does not contain any other harmful substances. High-quality products are also certified for low VOC emissions.

11. How does it improve a building’s energy efficiency?

By providing a continuous layer of insulation, it minimizes heat transfer, reduces thermal bridging, and lowers a building’s energy consumption for heating and cooling, leading to significant cost savings.

12. Can it be used in facades?

Yes, its high compressive strength and dimensional stability make it an ideal choice for external wall insulation systems, where it can be mechanically fastened or adhesively bonded and covered with a finishing system.

13. How long does the insulation last?

The boards are extremely durable and dimensionally stable. They will not settle, sag, or degrade over time, ensuring their thermal and physical properties are maintained for the lifetime of the building.

14. What international standards do these boards comply with?

They are manufactured to meet stringent international standards, such as ASTM C-612 and EN 13162, which specify requirements for mineral fiber board thermal insulation.

15. Are there different facing options?

Yes, the boards are often available with or without facings. Common facings include aluminum foil or a black fiberglass veil to serve as a vapor barrier, provide added protection, or enhance aesthetics.

16. What is the difference between Rockwool HD Board and LD Board?

HD (High-Density) Board is more rigid and has higher compressive strength, making it suitable for load-bearing applications. LD (Low-Density) Board is more flexible and is used for non-load-bearing applications like filling wall cavities or drywalls.

17. Is it easy to cut and install?

Yes, despite its rigidity, the board can be easily cut to size with a sharp serrated knife, making the installation process straightforward.

18. Does it contribute to green building certifications?

Yes, its high energy-saving potential and use of natural, abundant raw materials (rock) can help a building earn credits for certifications like LEED.

19. Where can one get technical support and purchase this product?

A specialized supplier like Gitco-sa.com, as an authorized distributor, can provide the necessary technical data sheets, certifications, and expert advice for specific project requirements.

Reviews

There are no reviews yet.