Wired Blanket: High-Temp Industrial Insulation

Wired Blanket is a high-density, flexible thermal and acoustic insulation blanket, featuring rock wool fibers stitched to a galvanized or stainless steel wire mesh for enhanced durability. It’s ideal for high-temperature and fire-safe applications. Gitco-sa.com provides a complete range of wired blankets with competitive prices across Saudi Arabia, UAE, and Bahrain.

Description

Rockwool Wired Blanket is a high-density insulation roll produced from mineral rock fibers spun from molten basalt and bonded with a thermosetting binder. The blanket is mechanically stitched to a hexagonal wire mesh made of either galvanized or stainless steel, forming a flexible, durable roll. This design allows the blanket to conform easily to irregular surfaces, making it a versatile solution for a wide range of industrial applications.

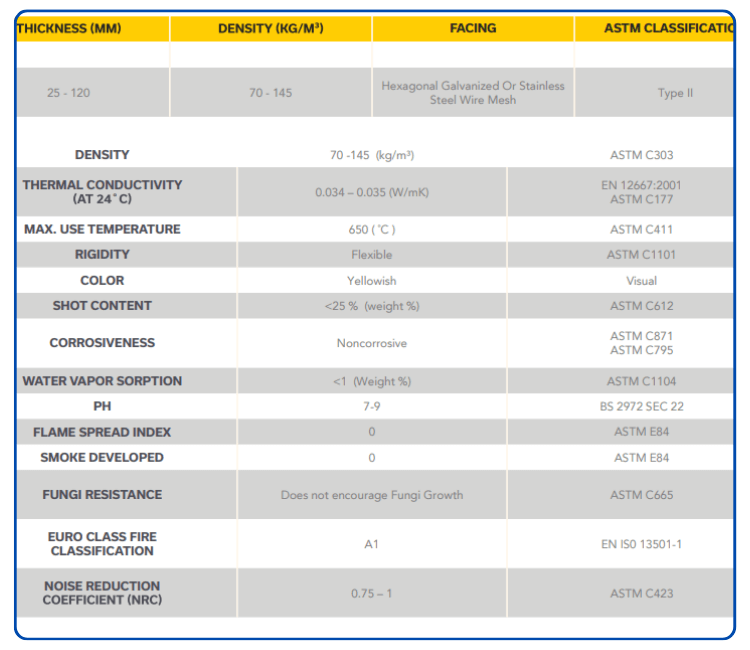

The product offers excellent thermal conductivity, ranging from 0.034 to 0.035 W/m.K at 24°C, and can withstand maximum use temperatures of up to 650°C. Its high density (70-145 kg/m³) provides superior acoustic performance, with a Noise Reduction Coefficient (NRC) of 0.75 to 1.0. The Wired Blanket is non-combustible with a Euro Class A1 fire classification, and has a Flame Spread Index of 0 and a Smoke Developed rating of 0, ensuring maximum fire safety. It is also non-corrosive and does not encourage fungi growth, ensuring a long-lasting and reliable insulation solution. Gitco-sa.com offers a complete range of Wired Blankets in various thicknesses from 25 mm to 120 mm to meet specific project requirements.

Key Applications of Rockwool Wired Blanket:

- High-Temperature Industrial Equipment: Ideal for insulating boilers, furnaces, kilns, and other industrial machinery to conserve energy and provide personnel protection.

- Large-Diameter Pipes and Vessels: The blanket’s flexible nature makes it perfect for wrapping large pipes, tanks, and vessels.

- Ductwork: Provides comprehensive thermal and acoustic insulation for HVAC ducts in commercial and industrial settings.

- Fireproofing: Used as a fire-resistant barrier in critical safety applications.

Our Cavity Panels prices are the Lowest for Cavity Panels products, and we provide budget-friendly Loose Wool in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia, UAE, and Bahrain, with a complete range to meet all your project needs.

Know more about Rockwool Wired Blanket:

1. Product & Composition

- What is a Rockwool Wired Blanket?

It’s a flexible, rolled insulation blanket made from non-combustible rock wool fibers. A galvanized or stainless steel hexagonal wire mesh is stitched to one or both sides to provide stability, strength, and ease of installation. - What is the primary material used?

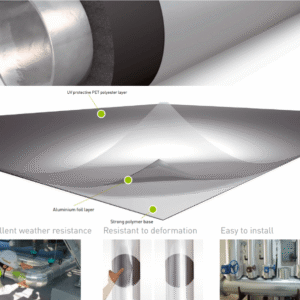

It’s made from mineral rock fibers spun from molten basalt, a type of volcanic rock. - What is the purpose of the wire mesh?

The wire mesh provides mechanical support, allowing the blanket to hold its shape around large, irregular surfaces like ducts, vessels, and tanks. It also adds durability and tensile strength, preventing the blanket from sagging or slumping. - What is the difference between galvanized and stainless steel mesh?

Galvanized mesh is a more cost-effective option for less corrosive environments. Stainless steel mesh is more durable and provides superior corrosion resistance in harsh, humid, or chemical-rich environments, such as in marine or chemical processing applications.

2. Performance & Properties

- What is the typical density of these blankets?

Wired blankets are high-density products, typically ranging from 80 kg/m³ to 120 kg/m³, which contributes to their excellent acoustic and thermal performance. - What is its fire rating?

Rockwool wired blankets are non-combustible and have a Euroclass A1 fire rating, the highest possible classification. They have a melting point exceeding 1000°C (1832°F). - What is their maximum service temperature?

They are designed for high-temperature applications, with a maximum service temperature up to 650°C (1200°F), making them suitable for boilers, kilns, and ovens. - How do they perform as a thermal insulator?

Their dense, fibrous structure effectively traps air, resulting in a very low thermal conductivity (k-value), typically around 0.040 W/m·K at 70°C. - Do they provide soundproofing?

Yes, their high density and fibrous composition make them excellent sound absorbers, effectively reducing noise from industrial equipment, pipes, and ducts. - Are they resistant to moisture?

Yes, rock wool is naturally hydrophobic. It repels water and will not absorb moisture, which prevents a loss in thermal performance and inhibits the growth of mold and fungi.

3. Applications & Installation

- Where are Rockwool Wired Blankets typically used?

They are primarily used in industrial and high-temperature applications, including:- Boilers, vessels, and tanks

- Large-diameter pipes and ducts

- Power plants and refineries

- Heat exchangers and ovens

- How are they installed?

The flexible blanket is wrapped around the object to be insulated. The wire mesh is then secured with fasteners like insulation pins or wires to hold it in place. The seams are then sealed to create a continuous barrier. - Is it suitable for marine and offshore applications?

Yes, they are highly suitable, especially when reinforced with stainless steel mesh, due to their excellent fire, thermal, and corrosion-resistant properties in harsh, humid, and saltwater environments. - Do they reduce corrosion under insulation (CUI)?

Yes, by being water-repellent and chemically inert, they help prevent moisture from reaching the metal surface, which is a major cause of CUI in industrial settings. - What is the typical size of a wired blanket roll?

They are available in rolls with various lengths, widths (e.g., 0.6m or 1.2m), and thicknesses (e.g., 25mm to 100mm). The specific size depends on the application. - Are they easy to handle and cut?

Despite their high density, the blankets are flexible and can be easily cut to size with a serrated knife or shears, making the installation process efficient.

4. Standards & Sourcing

- What international standards do they comply with?

They are manufactured in accordance with ASTM C-592, a standard specification for metal-mesh covered mineral fiber insulation for industrial applications. - What does the ASTM C-592 standard cover?

This standard specifies the composition, dimensions, and physical properties of the blanket, including its maximum use temperature, thermal conductivity, and moisture vapor sorption. - Are these products considered sustainable?

Yes, they are made from an abundant natural resource (rock) and are chemically and biologically inert. Their energy-saving properties also significantly reduce a building or facility’s carbon footprint. - Where can one find a reliable supplier for these blankets in the Middle East?

Authorized suppliers such as Gitco-sa.com are key suppliers in the GCC, providing certified products that meet regional and international standards.

Reviews

There are no reviews yet.