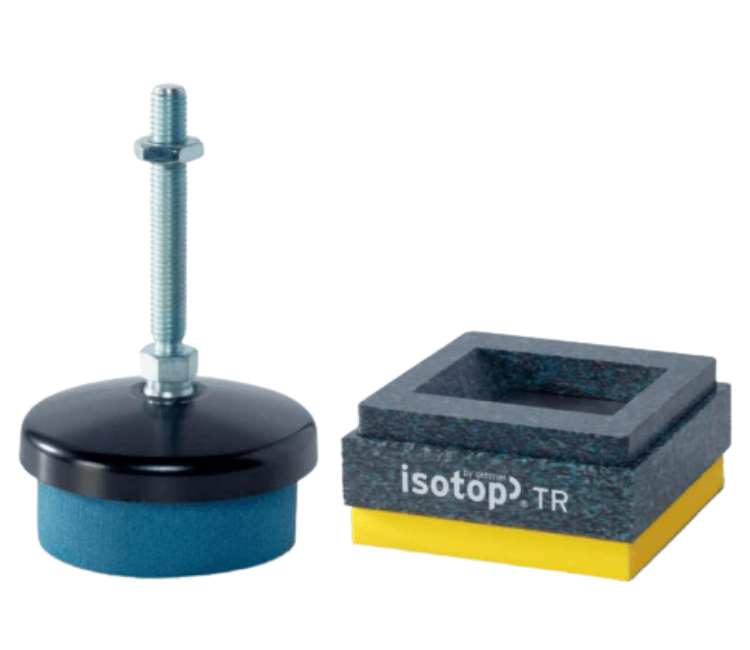

Getzner Sylomer Polishing Pads: Elastic Compensation Layer

Getzner Sylomer polishing pads (Elastic Compensation Layers) are high quality components vital for achieving fast, precise, and uniform surface finishing, particularly for sensitive materials like plastic lenses. Gitco-sa.com supplies the complete range of these best isolation products across Saudi Arabia.

Description

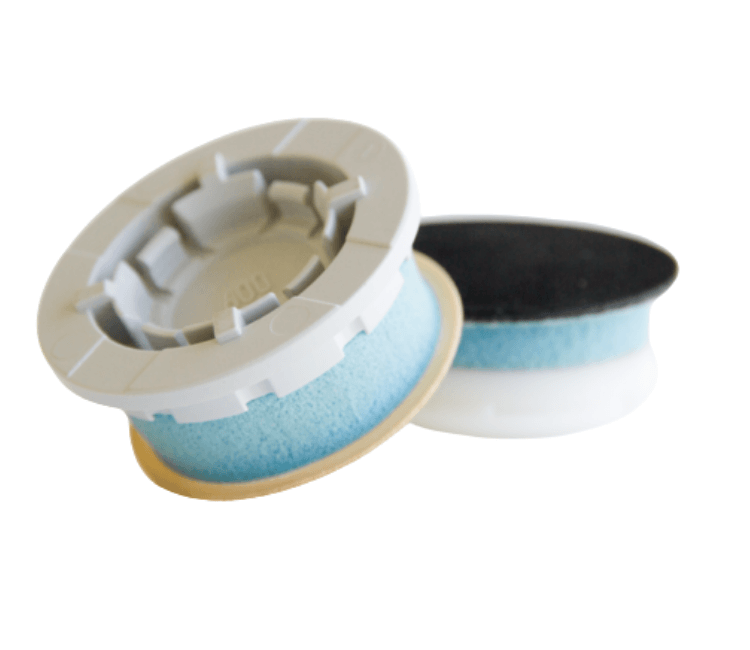

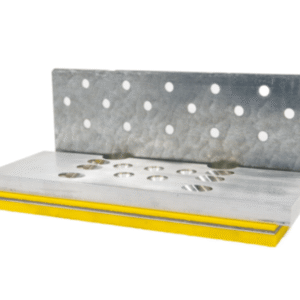

Getzner Sylomer polishing pads represent a specialized application of high-performance polyurethane, functioning as an elastic compensation layer within polishing tools. Crucial for industries demanding extreme surface precision, these pads ensure uniform pressure distribution between the polishing film and the substrate (e.g., plastic spectacle lenses), enabling fast and efficient processing of even the most sensitive materials.

The unique material combination provides a special blend of spring and damping characteristics, which stabilizes the polishing process and achieves superior surface quality while minimizing material usage and reducing production costs. Key technical features of these high quality pads include excellent recovery (allowing for repeated use), a strong connection to both polishing films and plastic substrates, and the benefit of no permeation of constituents that could contaminate the workpiece.

Product Variations and Range

Gitco-sa.com provides the complete range of Sylomer polishing pads to fit diverse equipment and requirements:

-

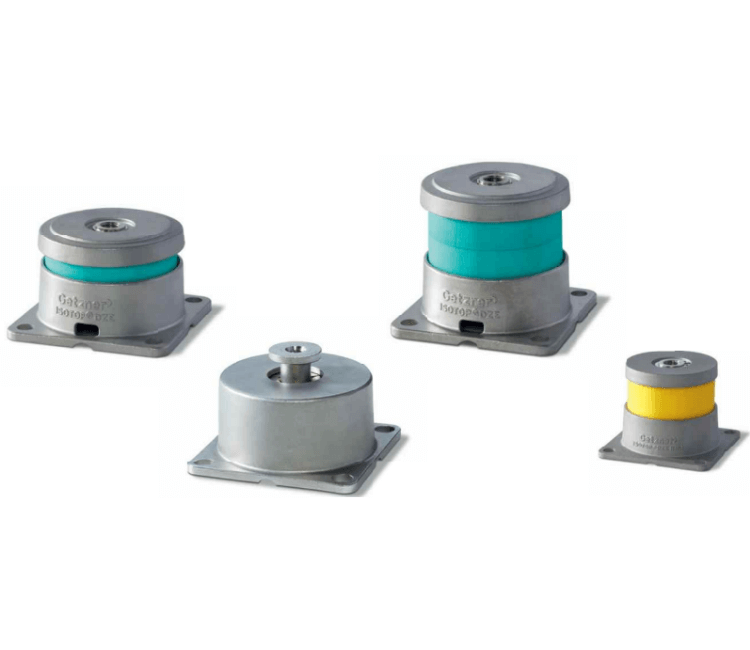

Custom Shapes and Dimensions: Getzner offers a wide range of shapes, ensuring the pad perfectly fits various polishing tools and machine types, which is essential for uniform pressure across the entire surface.

-

Varying Hardness and Density (Implicit): While not explicitly listed by code, Sylomer® is available in various densities, allowing for custom solutions that fine-tune the stiffness and damping necessary for processing different materials (glass, plastic, metal) and achieving varying surface finishes.

-

Optimal Processing: The pads are designed to maximize the performance of the polishing film, facilitating quick and efficient material removal while maintaining surface integrity.

Key Applications of Polishing Pads:

-

Optical Industry: The primary application is the polishing of plastic spectacle lenses, where surface quality is paramount, and materials are extremely sensitive to pressure variation.

-

Precision Surface Finishing: Used in the general industry for polishing other sensitive, high-value surfaces, such as high-tech screen glass, electronic components, or fine metalwork.

-

Micro-machining/Grinding: Any process requiring an elastic layer to dynamically compensate for micro-irregularities and ensure consistent force application.

We guarantee that our Sylomer® polishing pads are the best isolation products for achieving industrial surface perfection. Gitco-sa.com ensures the complete range of these high quality components is available for delivery and support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about polishing pads:

- What are Sylomer® polishing pads from Getzner?They are elastic compensation layers or pads made from the Sylomer® polyurethane elastomer, specifically manufactured for use in polishing tools.

- What is the main industrial application for these pads?They are extensively used in the optical industry, particularly for the precise polishing of high-end lenses, such as plastic spectacle lenses and varifocal lenses.

- What is the primary function of the pad during polishing?The pad acts as an elastic levelling layer that compensates for minor tolerances and irregularities, ensuring uniform contact pressure across the entire surface being polished.

- What material is Sylomer® in this context?It is a specialized mixed-cell polyurethane elastomer that combines high resilience (spring-like characteristics) with good damping properties.

- How do the pads help with sensitive materials?They enable the fast and efficient machining of extremely sensitive plastic materials (like spectacle lenses) while being gentle enough to avoid surface damage.

- What key material property ensures successful polishing?The pads have excellent recovery (rebound resilience), meaning they quickly and reliably return to their original shape after deformation, which is crucial for continuous polishing cycles.

- Do the pads help reduce polishing time?Yes, their tolerance compensation function allows for quicker and more efficient processing, leading to significantly shorter polishing times.

- Can the pads be used for polishing complex shapes?Yes, they enable the polishing of smaller radii and complex lens geometries, which is essential for customized varifocal lenses.

- How do the pads prevent material contamination?A unique property is that there is no permeation of constituents from the pad material, preventing contamination of the polishing film or plastic lens substrates.

- Do the pads extend the service life of polishing machines?Yes, by absorbing mechanical stresses and ensuring smooth operation, they contribute to lower life-cycle costs for the machine due to an extended service life.

- Are the Sylomer® pads available in different shapes?Yes, Getzner offers a wide range of shapes and geometries, including complex punched and molded parts, to perfectly match the design of various CNC polishing machines.

- Are the pads used in CNC machines?Yes, they are commonly used on modern CNC (Computer Numerical Control) machines in the optical industry.

- Do the pads offer cost savings?Yes, they allow for considerable cost savings by often reducing the need for multiple polishing tools and enabling the use of less polishing material.

- Is the pad material available for different load requirements?Yes, like Sylomer® vibration isolation products, the material is available in different densities to ideally suit various pressure and load ranges during the polishing process.

- Do the pads provide an excellent connection to the polishing film?Yes, they are engineered to provide an excellent connection to both the polishing film and the underlying plastic substrates.

- What is the typical mechanical loss factor (n) of Sylomer®?The mechanical loss factor (n) for Sylomer® generally ranges from 0.09 to 0.25, providing ideal damping characteristics for precision applications.

- What is the typical operating temperature range?The material maintains its properties within a broad operating temperature range, typically from -30 °C to +70 °C.

- Is the material flame-retardant?There are specialized variants, such as Sylomer® Marine FR, which are flame-retardant and developed for safety-critical applications, although the standard polishing pads may have different classifications.

- Is the product primarily used for vibration isolation in this context?While the material is famous for vibration isolation, its primary role in polishing is as a flexible compensation layer to ensure pressure uniformity, with its inherent damping being a secondary benefit.

Brand

Getzner

Reviews

There are no reviews yet.