Getzner Isotop Vibration Damper: Noise Reduction & Machine Stability

Getzner Isotop® vibration dampers are high quality components designed for optimum stability, effectively reducing mechanical vibrations and noise in machines. Gitco-sa.com offers the complete range of these best isolation products across Saudi Arabia.

Description

Getzner Isotop® vibration dampers are fundamental components in industrial systems, playing a vital role in the reduction of both mechanical vibrations and noise transferred from operating devices to the building structure and surrounding environment. By efficiently absorbing these vibrations, the dampers prevent unpleasant noise disturbance, significantly prolong the service life of the equipment, and enhance comfort levels in working areas.

These dampers are designed for optimum stability at a relatively low natural frequency (as low as 7.4 Hz), ensuring effective isolation. They feature a durable construction, often including metal caps and high corrosion protection (like zinc-nickel coating), ensuring a long service life and simple installation. Their primary benefit is the significant reduction of primary and secondary noise, making them some of the best isolation products for compliance with industrial noise regulations.

The Complete Range of Isotop® Vibration Dampers

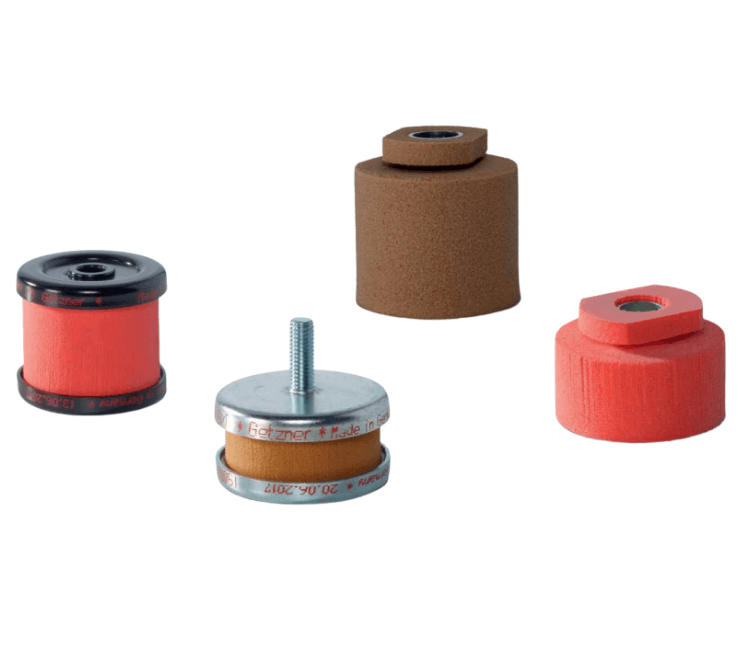

Gitco-sa.com provides the complete range of Isotop® vibration dampers, offering solutions for varied load requirements and installation constraints:

-

Isotop® MSN-Damp (Standard Damper): Features metal caps and threaded fastening, suitable for general machinery with load ranges up to 35 kg per damper. Offers high corrosion protection and multiple attaching options.

-

Isotop® Compact (Low Installation Height): Designed for applications with restricted vertical space, handling loads between 4 kg and 95 kg. Features a low overall height of 28 mm and can also be used as an anti-slip machine mounting.

-

Sylomer® Compressor Grommet CGR: Specialised high-performance dampers for lighter equipment like compressors, covering load ranges between 3 kg and 25 kg. Features an integrated steel case for secure mounting with high starting torque, emphasizing high quality in compact applications.

Key Applications

-

HVAC and Climate Control: Damping vibrations in heat pumps, air conditioning units, fans, and ventilators to prevent noise transfer into building spaces.

-

Compressors and Small Pumps: Providing highly effective isolation for small-to-medium-sized reciprocating machinery to ensure quiet and efficient operation.

-

Sensitive Electronic Equipment: Used to reduce secondary noise and mechanical stress on control cabinets and sensitive measurement devices.

We guarantee that our Isotop® vibration dampers are the best isolation products for noise and vibration reduction. Gitco-sa.com ensures the complete range of these high-quality components is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about Isotop® vibration dampers:

- What are Getzner Isotop® vibration dampers?They are a range of machine mountings that combine elastic polyurethane (PU) materials (like Sylomer® or Sylodyn®) with robust metal components to create a stable yet vibration-isolating element.

- What is the main problem these dampers solve?They prevent the transmission of structure-borne noise and mechanical vibrations generated by machinery from reaching the surrounding building structure or sensitive equipment.

- What specific Getzner materials are integrated into the dampers?The isolating layer is typically made from Sylomer® (for general damping) or Sylodyn® (for higher resilience and stability under high loads), or Sylodamp® (for high damping of impacts/shocks).

- What is the primary application sector for Isotop dampers?They are predominantly used in Building Services Equipment (BSE), including HVAC systems (fans, air-handling units, heat pumps, cooling towers), pumps, and compressors.

- How do the dampers differ from simple rubber buffers?Isotop dampers use engineered PU elastomers whose elastic properties can be precisely calculated (predicting the natural frequency), providing a much more accurate and consistent vibration reduction than generic rubber.

- What is the significance of the dampers’ “low natural frequency”?A low natural frequency is crucial for effectively isolating low-frequency vibrations (e.g., the “humming” from slow-running compressors or fans), which travel the furthest and cause the most disruption.

- What is the typical natural frequency range for the compact models?Compact models like the Isotop® Compact are designed for low installation heights and achieve a natural frequency starting from approximately 9.9 Hz.

- What is the natural frequency of the highest-performing spring-based Isotop products?Some spring-based Isotop products (like the SD series) can achieve a natural frequency as low as 3.2 Hz for optimal low-frequency isolation.

- Do the dampers reduce airborne noise?Yes, by eliminating vibration transmission into the structure, they also significantly reduce the secondary airborne noise that is radiated from vibrating surfaces like ceilings and walls.

- Do the dampers offer good stability under eccentric loads?Yes, the combination of the stiff metal casing and the elastic PU core provides optimum stability for the mounted machine, even when the center of gravity is slightly eccentric.

- What is the load capacity of the smallest Isotop® Compact damper?The smallest Isotop® Compact variant can handle a static load starting from approximately 4 kg (or 41 N) per element.

- What is the maximum load capacity for the Isotop® Compact series?The Isotop® Compact series can handle loads up to approximately 95 kg per element.

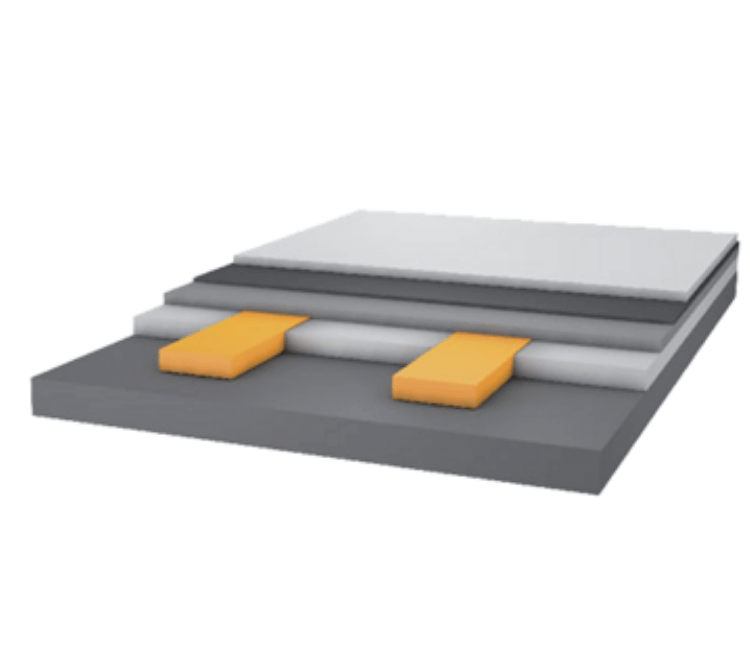

- Are there Isotop products for very heavy loads?Yes, products like the Isotop® SE sandwich pads or DSD block elements are designed for much heavier machinery, with load capacities extending into the tons per element.

- Can the dampers be used for machine leveling?Yes, certain spring-based Isotop models are compatible with height adjustment accessories (like the Isotop® NV) to allow for precise leveling of machinery.

- Are the dampers suitable for outdoor use?Yes, the metal caps are often finished with coatings like galvanisation or zinc-nickel coating for a high level of corrosion protection, making them ideal for outdoor installations (e.g., rooftop HVAC units).

- How is the Isotop® Compact typically installed?The Compact series is designed for easy installation, often featuring an M8 internal thread and/or stud bolt for simple screw-fixing to the machine or base frame.

- What is the typical overall height of the Isotop® Compact?The Isotop® Compact models are known for their low installation height, typically around 28 mm to 30 mm, making them suitable for restricted spaces.

- What is the permissible temperature range for the dampers?The certified operating temperature range for the dampers is typically from 24-30 °C to +70 °C.

- Do the dampers require regular maintenance?No, the materials are highly durable, rot-proof, and designed to provide consistent performance over decades with an extremely low creep rate, resulting in reduced maintenance costs.

Brand

Getzner

Reviews

There are no reviews yet.