PIR insulation materials (Polyisocyanurate) for walls, roofs, floors.

PIR insulation materials (Polyisocyanurate foam) are rigid, closed-cell boards offering superior thermal efficiency (low 1$\lambda$-value) and excellent fire resistance for construction.2 Gitco-sa.com supplies a complete range of these high quality, best isolation products across Saudi Arabia.

Description

Polyisocyanurate (PIR) foam insulation is a cutting-edge, rigid, closed-cell thermal material widely recognized as an advancement of traditional Polyurethane (PUR) foam. Its superior performance is derived from a specialized chemical process that creates strong, heat-resistant isocyanurate ring structures. This results in enhanced fire resistance, excellent dimensional stability, and one of the lowest thermal conductivity values (λ≈0.022 W/(m⋅K)) among common insulants.

By achieving optimal thermal resistance (high R-value) with minimal thickness, PIR boards offer significant space-saving advantages critical in modern commercial and residential construction across Saudi Arabia. This material also exhibits high durability, excellent compressive strength, and low water absorption, ensuring reliable performance that lasts the lifetime of a building (up to 50 years).

The Complete Range of PIR Insulation

Gitco-sa.com ensures a complete range of PIR insulation is available, distinguished primarily by density, facing, and application type:

-

Standard Rigid Boards (Density≈30-32 kg m³): Available in various thicknesses (e.g., 20 mm to 200 mm), typically faced with low-emissivity aluminum foil. The foil enhances thermal performance by acting as a radiant barrier and often serves as an integrated vapor control layer.

-

Specialized Facing (e.g., Glass Tissue, Bitumen): Products with non-foil facings designed for specific applications, such as direct torch-on membrane bonding in warm flat roof systems or when bonding directly with plasterboard adhesive.

-

High-Density Blocks & Pipe Sections (Density 80 kg m³ and up): Used for demanding industrial applications, including high-load bearing thermal supports and pre-formed pipe insulation (e.g., for HVAC, oil & gas lines). These variations offer higher compressive strength for heavy equipment support.

We guarantee that our PIR insulation materials are the best isolation products for long-term energy efficiency and fire safety. Gitco-sa.com offers the complete range of these high quality products across Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and all of Saudi Arabia.

Key Applications of PIR Insulation:

-

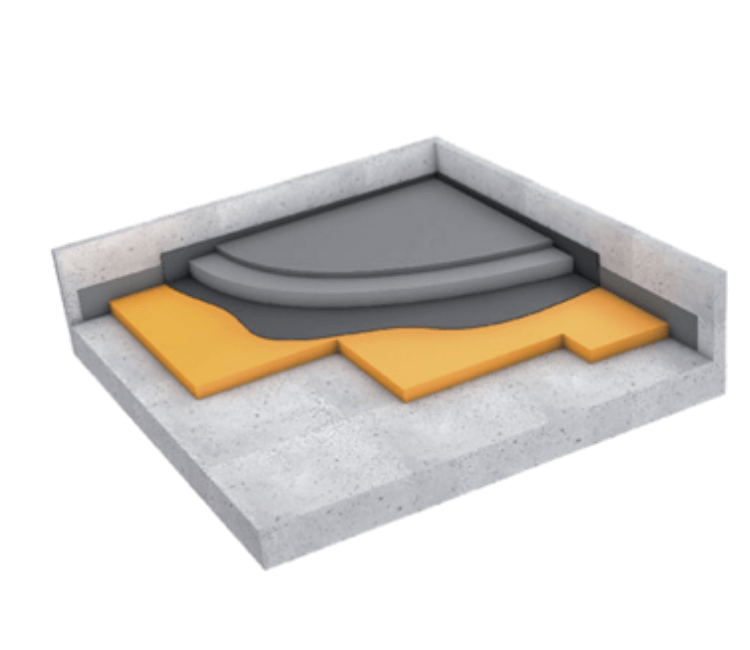

Roof Insulation: Used extensively in flat roofs (warm roof construction) and pitched roofs (above, below, or between rafters) to maximize thermal efficiency.

-

Wall Insulation: Ideal for internal linings, external wall insulation systems, and masonry cavity walls (full and partial fill solutions).

-

Floor Insulation: Used in concrete ground floors, installed above or below the slab, benefiting from the material’s excellent compressive strength.

-

HVAC & Industrial: Prefabricated pre-insulated duct panels and pipe sections for high-performance thermal control in demanding air conditioning, petrochemical, and cold insulation environments.

Know more about PIR Insulation:

1. Product Identity and Chemical Composition

- What is Polyisocyanurate (PIR) foam?

PIR is a thermoset plastic foam, chemically modified from polyurethane (PUR), typically produced as rigid boards, slabs, or pipe sections for thermal insulation. - How is PIR chemically different from standard Polyurethane (PUR) foam?

PIR is produced with a higher proportion of MDI (methylene diphenyl diisocyanate) and uses a polyester-derived polyol, leading to the formation of a rigid, heat-stable isocyanurate ring structure. - Why is the PIR chemical structure advantageous?

The complex, highly cross-linked isocyanurate ring structure provides PIR with greater stiffness and enhanced chemical/thermal stability compared to PUR. - What does the term “Polyiso” refer to?

“Polyiso” is an industry abbreviation commonly used in North America for Polyisocyanurate foam insulation. - What is the cell structure of PIR foam?

PIR is a rigid, closed-cell foam, where the gas trapped within the cells provides the primary thermal resistance.

2. Thermal Performance and Efficiency

- What is the key thermal benefit of PIR insulation?

PIR boasts one of the highest R-values per inch (thermal resistance) among common insulation materials, typically ranging from 5.8 to 7.0 per inch (RSI 0.93 to 1.23 m2K/W per 25 mm). - What is the typical thermal conductivity (𝜆 or k-factor) of PIR?

PIR has a very low thermal conductivity, often around 0.020 to 0.023 W/(m·K), making it highly effective at resisting heat flow.

- How does the high R-value benefit construction?

It allows builders to achieve required thermal performance (U-values) with less material thickness, minimizing the building’s footprint and maximizing usable space. - Why do PIR boards often feature foil facers?

The facers (typically aluminum foil) provide an excellent vapor barrier to prevent moisture ingress and enhance the board’s surface strength and adherence to the foam core. - Does the thermal performance of PIR change over time?

The thermal performance can slightly decrease over time (known as “aging”) as the low-conductivity blowing agent gases within the closed cells slowly diffuse and are replaced by air.

3. Fire Resistance and Safety

- How does PIR react to fire compared to EPS or XPS?

PIR is a thermoset material, meaning when exposed to flame, it typically chars and retains its shape instead of melting and dripping like the thermoplastic foams (EPS/XPS). - What fire safety rating can PIR achieve?

PIR is often classified as fire-retardant (e.g., Euroclass B or D), and is noted for producing less smoke and toxic fumes than PUR, particularly when installed correctly with a non-combustible barrier like drywall. - Why is PIR often considered safer than PUR in a fire?

The isocyanurate rings in PIR provide greater thermal stability; the chemical breakdown starts at a higher temperature (above 200 °C) compared to PUR, which begins to break down around 100 °C. - What is the common temperature resistance range for PIR?

PIR exhibits excellent stability over a wide service temperature range, typically from -183 °C (cryogenic) up to +149 °C.

4. Applications and Forms

- What are the main applications for PIR in commercial construction?

PIR is widely used for commercial roofing systems (flat/low-slope roofs), continuous wall insulation (sheathing), and floor insulation. - How is PIR used in HVAC systems?

PIR foam panels laminated with aluminum foil are used for the fabrication of pre-insulated ductwork, which is highly efficient and resistant to moisture. - Is PIR used in industrial applications?

Yes, it is used extensively for pipe insulation, chilled water lines, cryogenic applications (like LNG), and in cold storage facilities due to its excellent moisture resistance and low thermal conductivity. - In what physical forms is PIR insulation available?

PIR is available as rigid boards/slabs, pre-formed pipe sections, and as the core material for composite sandwich panels (e.g., for roofing and walls of factories/warehouses).

5. Sustainability and Durability

- How does PIR foam address environmental concerns regarding blowing agents?

Modern PIR products use hydrocarbon blowing agents (like pentane) that have Zero Ozone Depletion Potential (Zero ODP) and very low Global Warming Potential (Low GWP). - What is the typical lifespan and durability of PIR insulation?

PIR has a robust, closed-cell structure that provides high compressive strength and excellent moisture resistance, resulting in a long service life, often exceeding 50 years when properly installed.

Brand

Zhenshen Insulation

Zhenshen Insulation is a trusted global manufacturer recognized for delivering high-performance insulation solutions, particularly their advanced Cellular Glass (Foam Glass) products. As a supplier of Aramco and SABIC approved products, Zhenshen meets the rigorous quality, safety, and durability standards demanded by the largest industrial and energy corporations in the Kingdom of Saudi Arabia. All Zhenshen products comply with stringent ASTM standards, guaranteeing reliability for critical applications.

Zhenshen Cellular Glass Insulation (Foam Glass/Foamglas) is the cornerstone of their industrial offering, renowned for its:

-

Absolute Vapor Impermeability: The closed-cell structure makes it a definitive vapor barrier, preventing moisture migration and eliminating the risk of Corrosion Under Insulation (CUI), vital for long-term reliability in cold insulation and hot insulation systems.

-

Non-Combustibility: Being inorganic, it is inherently fireproof, providing a crucial safety layer in LNG tank, pipeline, and chemical processing environments.

-

High Compressive Strength: Its rigidity makes it ideal for high-load applications, including cryogenic tank bases and pipe supports, ensuring system integrity.

The Complete Range of Zhenshen Insulation Products

Gitco-sa.com supplies the complete range of high quality Zhenshen Insulation materials, ensuring compliance and availability for major projects:

-

Cellular Glass Pipe Sections: Pre-formed insulation for pipeline insulation in LNG, cold, hot, and medium-temperature systems. Available for various pipe sizes and thicknesses, compliant with ASTM standards.

-

Foam Glass Slabs & Boards: Used for LNG tank bases (cryogenic systems), equipment, vessels, roof insulation, and wall insulation in industrial and commercial building insulation projects.

-

Tapered & Curved Sections: Custom Foam Glass segments for precise insulation of large vessels, tanks, and structural elements, ensuring thermal continuity.

-

Specialized Industrial Grades: Products engineered specifically for the extreme conditions found in petrochemical and hydrocarbon processing systems, carrying the distinction of being Aramco and SABIC approved products.

We guarantee that our Zhenshen Insulation products are the best isolation products for achieving maximum durability and safety. Gitco-sa.com ensures the complete range of these high quality, Aramco and SABIC approved materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications

-

Industrial/Energy: LNG tank and cryogenic tank insulation, pipeline insulation (hot and cold), and process equipment in Hydrocarbon Processing and Chemical Processing Systems.

-

Building & Construction: Roof insulation, wall insulation, and structural insulation for commercial and industrial buildings requiring high fire ratings and moisture control.

-

Waterproofing: Used in conjunction with construction and roofing materials due to its zero-permeability.

Reviews

There are no reviews yet.