Prefabricated Perlite Concrete Blocks (PCBs) for Steel Tank Base

Perlite Concrete Blocks (PCBs) are high load bearing pre-fabricated units designed as the essential insulating base for large steel tank bases (cryogenic and industrial).1 They combine superior strength ( ≥5.5 N/mm² avg.) with low thermal conductivity (≤0.25 W/(m.K)). Gitco-sa.com supplies the complete range of these best isolation products across Saudi Arabia.

Description

Pre-fabricated Perlite Concrete Blocks (PCBs) serve a dual critical function beneath large storage tanks, particularly those storing cryogenic (e.g., LNG, LPG) or high-temperature industrial materials: they provide high structural support against static and dynamic loads while offering superior thermal insulation.Without PCBs, the massive weight of the tank and its contents would create an unavoidable thermal bridge, leading to huge energy loss and, in cold applications, potentially damaging the foundation slab through freezing and cracking (frost heave).

PCBs are manufactured from a specialized mix of expanded perlite aggregate, Portland cement, and admixtures, often reinforced with steel bars and lifting hooks for better tensile strength and easy installation. This unique composition delivers:

-

High Compressive Strength: Averaging greater than 5.5 N/mm² after 28 days (for 1000 kg m³ density), making them ideal for heavy industrial structures.

-

Low Thermal Conductivity: Extremely low λ-values (≤ 0.25 W/m.K) 0°C) ensure optimal thermal isolation at negative temperatures.

-

Non-Combustibility: The cement and perlite mixture is inherently non-combustible, adding a crucial layer of fire safety to the tank base.

The Complete Range of Perlite Concrete Blocks (PCBs)

Gitco-sa.com provides a complete range of high quality PCBs, custom-engineered to meet specific project demands:

-

Density/Strength Grades: Available in various densities, such as PCB-1,000 (≈1000 kg/ m³ and ≥ 5.5 N/mm²) and PCB-1,200 (≈1200 kg/m³ and ≥ 7 N/mm²), allowing engineers to precisely match load requirements with thermal performance.

-

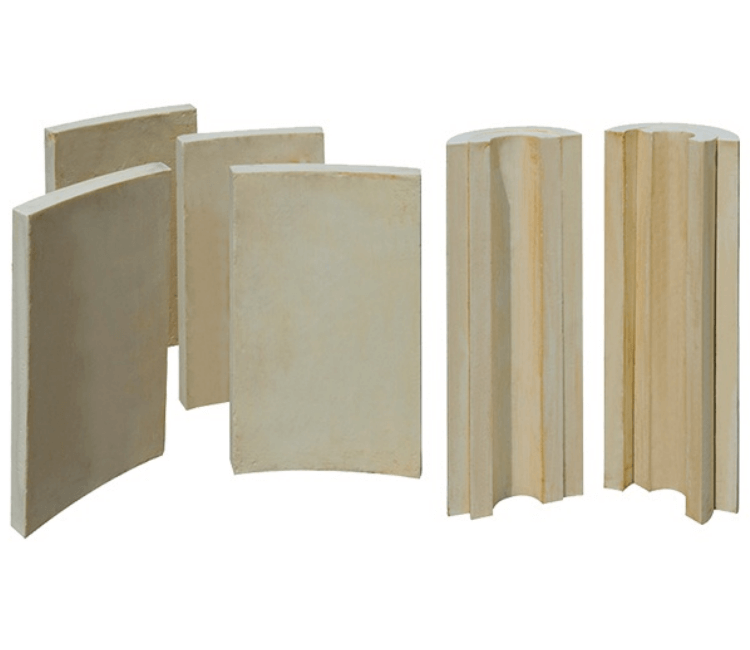

Custom Shapes (Trapezium): PCBs are often manufactured in a trap ezium shape to form a snug, continuous ring beam beneath the tank wall, minimizing joints and optimizing the thermal barrier around the curvature of the tank.

-

Special Reinforcement: For ultra-low temperatures, such as LNG tanks operating at -165 °C, blocks are reinforced with stainless steel bars instead of carbon steel to prevent embrittlement.

These are truly the best isolation products for providing both structural integrity and thermal continuity in critical industrial facilities.

Key Applications of Perlite Concrete Blocks (PCBs):

-

Cryogenic Storage Tanks: Primarily used for the bottom ring beam insulation of double-walled tanks storing Liquefied Natural Gas (LNG), Propane (LPG), Ethylene, and other industrial gases.

-

Hot Storage Tanks: Used to thermally isolate tank floors from the foundation slab to prevent heat loss and ensure process stability.

-

Industrial Infrastructure: Any large, heavy structure requiring structural support combined with robust thermal and fire protection properties.

We ensure the complete range of these high quality Perlite Concrete Blocks is available for delivery and complex project support across Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and all of Saudi Arabia.

Know more about Perlite Concrete Blocks (PCBs):

1. Product Identity and Composition

- What are Pre-fabricated Perlite Concrete Blocks (PCBs)?

They are engineered, lightweight blocks made from a cementitious binder (usually Portland cement) mixed with expanded perlite aggregate and special admixtures.

- What is the main component that gives PCBs their insulating properties?

The main component is expanded perlite aggregate, which is a volcanic glass that “pops” when heated, creating countless tiny, glass-sealed air bubbles that drastically reduce thermal conductivity.

- Are PCBs considered lightweight or conventional concrete?

PCBs are considered lightweight insulating concrete, with densities significantly lower than conventional concrete, typically ranging from 800 to 1,200 kg/m³.

- Are PCBs reinforced?

Yes, PCBs are typically steel-reinforced (with carbon steel or stainless steel bars) to improve their flexural and tensile strength, minimize breakages, and handle lifting stresses during installation.

- Why is stainless steel reinforcement sometimes required?

Stainless steel reinforcement is used in PCBs for cryogenic tanks (like LNG operating at -165 °C), as it prevents the embrittlement and thermal stress that regular carbon steel would undergo at such low temperatures.

2. Structural Function and Load Bearing

- What is the main purpose of using PCBs as a steel tank base?

The main purpose is to provide high structural support against static and dynamic loads while simultaneously offering excellent thermal insulation between the tank base and the foundation slab.

- Do PCBs support the entire tank base or just the periphery?

PCBs are primarily used to form the ring beam beneath the inner tank shell of double-walled cryogenic or low-temperature tanks, where the load is concentrated.

- What is the typical compressive strength of PCBs for tank applications?

The minimum compressive strength for various grades typically ranges from 3.0 N/mm² (≈435 psi) up to 8.0 N/mm² ( ≈1,160 psi), depending on the load requirement.

- What is the purpose of the special trapezium shape of the blocks?

The blocks are custom-cast in a trapezium shape to ensure a snug, circumferential fit around the curvature of the tank, minimizing joints and gaps.

- How do PCBs prevent corrosion?

By acting as a thermal break, they prevent the pipe or tank bottom from reaching the dew point of the surrounding environment, which eliminates condensation and significantly reduces the risk of Corrosion Under Insulation (CUI).

3. Thermal and Fire Performance

- Are PCBs suitable for cryogenic applications (e.g., LNG, LPG)?

Yes, PCBs are engineered specifically for this purpose, providing superior thermal insulation at negative temperatures to minimize heat leakage into the cold tank.

- What is the typical thermal conductivity (λ) of a standard PCB grade?

Thermal conductivity is low, with common grades showing values around 0.14 to 0.25 W/(m·K) at a mean temperature of 0 °C.

- Are PCBs fire-resistant?

Yes, PCBs are made from mineral components (perlite and cement) and are completely non-combustible, offering inherent fire protection for critical structures.

- How are PCBs protected from external moisture during storage/installation?

PCBs are usually manufactured with a special vapor barrier coating (often polyurethane) applied to all sides to prevent moisture ingress during storage and handling, preserving their dry thermal performance.

- What is the role of PCBs concerning seismic and dynamic forces?

They provide stable structural support that can withstand both the static load of the filled tank and the dynamic loads associated with operation and seismic activity.

4. Installation and Sourcing

- How are PCBs integrated into the overall tank foundation system?

PCBs are typically laid on top of a leveling concrete layer or a perlite leveling concrete layer placed above the main foundation slab.

- What is the typical installation process after the blocks are placed?

The joints between the blocks are sealed (often with a compatible insulating mortar or mastic), and then the top surface of the PCBs is prepared to receive the tank bottom plates.

- Why are PCBs often preferred over casting a perlite concrete ring beam on-site?

Pre-fabrication allows for stringent quality control over density, strength, and curing in a controlled factory environment, ensuring consistent performance and dimensional accuracy.

- What industry standards typically apply to the testing of PCBs?

PCBs are tested according to standards such as ASTM C495 (Compressive Strength) and ASTM C518 (Thermal Conductivity).

- Where can one purchase customized PCBs?

PCBs are custom-made according to project specifications and are supplied globally by specialized manufacturers and authorized distributors (like Gitco-sa.com) who provide technical design and installation support.

Brand

Zhenshen Insulation

Zhenshen Insulation is a trusted global manufacturer recognized for delivering high-performance insulation solutions, particularly their advanced Cellular Glass (Foam Glass) products. As a supplier of Aramco and SABIC approved products, Zhenshen meets the rigorous quality, safety, and durability standards demanded by the largest industrial and energy corporations in the Kingdom of Saudi Arabia. All Zhenshen products comply with stringent ASTM standards, guaranteeing reliability for critical applications.

Zhenshen Cellular Glass Insulation (Foam Glass/Foamglas) is the cornerstone of their industrial offering, renowned for its:

-

Absolute Vapor Impermeability: The closed-cell structure makes it a definitive vapor barrier, preventing moisture migration and eliminating the risk of Corrosion Under Insulation (CUI), vital for long-term reliability in cold insulation and hot insulation systems.

-

Non-Combustibility: Being inorganic, it is inherently fireproof, providing a crucial safety layer in LNG tank, pipeline, and chemical processing environments.

-

High Compressive Strength: Its rigidity makes it ideal for high-load applications, including cryogenic tank bases and pipe supports, ensuring system integrity.

The Complete Range of Zhenshen Insulation Products

Gitco-sa.com supplies the complete range of high quality Zhenshen Insulation materials, ensuring compliance and availability for major projects:

-

Cellular Glass Pipe Sections: Pre-formed insulation for pipeline insulation in LNG, cold, hot, and medium-temperature systems. Available for various pipe sizes and thicknesses, compliant with ASTM standards.

-

Foam Glass Slabs & Boards: Used for LNG tank bases (cryogenic systems), equipment, vessels, roof insulation, and wall insulation in industrial and commercial building insulation projects.

-

Tapered & Curved Sections: Custom Foam Glass segments for precise insulation of large vessels, tanks, and structural elements, ensuring thermal continuity.

-

Specialized Industrial Grades: Products engineered specifically for the extreme conditions found in petrochemical and hydrocarbon processing systems, carrying the distinction of being Aramco and SABIC approved products.

We guarantee that our Zhenshen Insulation products are the best isolation products for achieving maximum durability and safety. Gitco-sa.com ensures the complete range of these high quality, Aramco and SABIC approved materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications

-

Industrial/Energy: LNG tank and cryogenic tank insulation, pipeline insulation (hot and cold), and process equipment in Hydrocarbon Processing and Chemical Processing Systems.

-

Building & Construction: Roof insulation, wall insulation, and structural insulation for commercial and industrial buildings requiring high fire ratings and moisture control.

-

Waterproofing: Used in conjunction with construction and roofing materials due to its zero-permeability.

Reviews

There are no reviews yet.