Cellular Glass Pipe Insulation (ASTM Standard)

Cellular Glass Pipe Insulation ( ASTM Standard) is a rigid, closed-cell material offering complete moisture and vapor impermeability. It is one of the best isolation products for critical applications, providing high compressive strength and thermal stability across a wide temperature range. Gitco-sa.com supplies the complete range of this high quality insulation across Saudi Arabia.

Description

Cellular Glass Pipe Insulation is a premium, high-performance insulation material made from a network of hermetically sealed glass cells. Its unique, inorganic structure offers an unparalleled combination of properties essential for demanding industrial environments, particularly in the oil, gas, and petrochemical sectors. Crucially, it conforms to the relevant ASTM standards (e.g., ASTM C552), certifying its stringent quality and performance characteristics.

The material’s closed-cell nature ensures zero permeability to water, moisture, and vapor, making it the definitive solution for cold and cryogenic insulation systems where moisture ingress leads to system failure, corrosion under insulation (CUI), and energy loss.

Key benefits of Cellular Glass include:

-

Total Vapor and Moisture Barrier: Prevents freeze-thaw cycles and CUI, guaranteeing system integrity for the lifetime of the plant.

-

Non-Combustible and Fire Resistant: Being inorganic, it is inherently fireproof, meeting stringent safety standards.

-

High Compressive Strength: Its rigid structure can withstand significant external loads without deformation, making it ideal for pipe supports and heavy jacketing.

-

Wide Operating Temperature Range: Effective from cryogenic lows (e.g., -268 °C for LNG) up to high industrial temperatures (e.g., +482 °C).

The Complete Range of Cellular Glass Pipe Insulation

Gitco-sa.com offers a complete range of high quality Cellular Glass insulation, precisely pre-fabricated to industrial specifications:

-

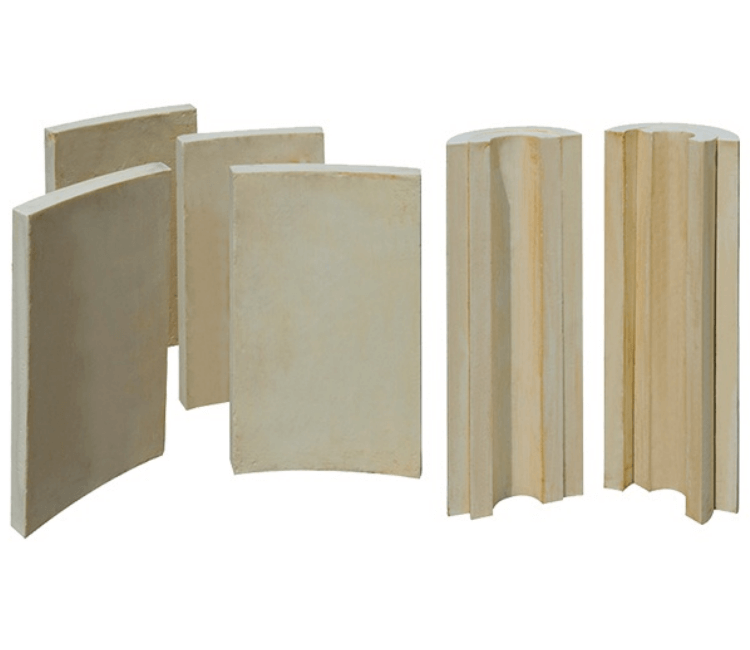

Pre-formed Pipe Sections: Available in half-sections (for NPS 1/2 to NPS 18) and curved segments (for larger NPS sizes) to perfectly fit all standard pipe diameters and flanges, minimizing gaps and installation time.

-

Block and Board Forms: Available for insulating large flat surfaces, equipment, vessels, and custom pipe fittings (elbows, tees).

-

Thickness and Density: Manufactured in a variety of thicknesses to meet specific thermal requirements and densities to match required compressive strengths, all conforming to ASTM Standard specifications.

-

Integrated Finishes: Often supplied ready for application with compatible coatings, mastics, and jacketing materials (e.g., aluminum or stainless steel) to complete the mechanical protection and vapor barrier.

We guarantee that our Cellular Glass Pipe Insulation materials are the best isolation products for long-term safety, efficiency, and system reliability. Gitco-sa.com ensures the complete range of these materials is available for delivery and complex project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications

-

Cryogenic and Cold Systems: Insulating pipelines and vessels for Liquefied Natural Gas (LNG), Liquid Oxygen, Ethylene, and chilled water.

-

Corrosion Under Insulation (CUI) Prevention: Used in both hot and cold services to eliminate the risk of moisture penetration, particularly in coastal or humid environments like Al-Khobar.

-

High-Temperature Process Piping: Insulating hot oil lines, steam pipes, and chemical process piping up to 482 °C where fire resistance is paramount.

-

Industrial Equipment: Insulation for storage tanks, towers, reactors, and heat exchangers requiring rigid, non-absorbent materials.

Know more about Cellular Glass Pipe Insulation:

- What is Cellular Glass Insulation?

It is a rigid, inorganic foam insulation material composed entirely of millions of sealed glass cells (hence “cellular glass”), giving it exceptional resistance to moisture and fire. - What is the primary ASTM Standard governing Cellular Glass Insulation?

The main standard is ASTM C552 (Standard Specification for Cellular Glass Thermal Insulation), which specifies its physical and performance requirements. - What are the key ingredients used to manufacture this material?

The material is manufactured by heating pulverized glass along with a small amount of a blowing agent (typically carbon) until it foams and solidifies into a closed-cell structure. - Is Cellular Glass considered organic or inorganic?

It is 100% inorganic, which means it cannot rot, support microbial growth, or be attacked by pests. - What is the main thermal benefit of its closed-cell structure?

The closed-cell structure makes the material absolutely impermeable to moisture and water vapor, guaranteeing that its thermal conductivity (λ) will not increase due to wetness. - Is Cellular Glass non-combustible?

Yes, because it is made purely of glass, the material is entirely non-combustible (does not burn) and has a flame spread and smoke developed index of zero. - How does Cellular Glass prevent Corrosion Under Insulation (CUI)?

It is a key CUI mitigation material because it is not only impervious to water but also non-absorbent and pH-neutral, preventing the creation of corrosive environments beneath the insulation. - Does it have high compressive strength?

Yes, Cellular Glass is a high-density, rigid insulation, often with a compressive strength of up to 6.9 N/mm² (1,000 psi) or more for its high-load grades. - What is the significance of its low coefficient of thermal expansion?

Its coefficient of thermal expansion is similar to that of carbon steel, minimizing thermal movement stresses at the pipe-to-insulation interface, which is critical in high-temperature systems. - What is the typical operational temperature range for Cellular Glass?

It is a highly versatile material covering a massive temperature range, typically from -268 °C (cryogenic) up to +482 °C (high-temperature steam). - What cryogenic applications use Cellular Glass?

It is the preferred insulation for extremely cold applications, such as LNG (Liquefied Natural Gas), LPG, liquid oxygen/nitrogen lines, and cold storage tanks. - What high-temperature industrial applications use it?

It is used for insulating steam lines, process piping, hot oil/gas lines, and equipment in chemical, petrochemical, and power generation facilities. - Is it suitable for underground use?

Yes, due to its high compressive strength, rigidity, and impermeability, it is an excellent choice for buried piping systems and trenches. - How is Cellular Glass used for pipe supports?

Due to its high compressive strength, it is often used to make load-bearing pipe supports that function as both insulation and structural elements, preventing thermal bridges. - Is the pipe insulation supplied in a custom form?

Yes, the material is supplied in various forms, including pre-formed pipe sections, segments, elbows, and bevelled lags to fit standard pipe sizes and components perfectly. - What standard governs the thermal conductivity of the material?

Its thermal conductivity (λ) is typically measured and reported in accordance with ASTM C177 or ASTM C518. - What type of adhesive or sealant is required for installation?

A specialized sealant/adhesive (often bitumen or a polymer-based mastic) is used to bond the sections and seal the joints, ensuring the entire assembly remains vapor-tight and monolithic. - Can the material be used without external jacketing?

While the material is inherently weather-resistant, it is almost always finished with an external metal jacketing (e.g., aluminum, stainless steel) or a protective finish for mechanical and UV protection.

Brand

Zhenshen Insulation

Zhenshen Insulation is a trusted global manufacturer recognized for delivering high-performance insulation solutions, particularly their advanced Cellular Glass (Foam Glass) products. As a supplier of Aramco and SABIC approved products, Zhenshen meets the rigorous quality, safety, and durability standards demanded by the largest industrial and energy corporations in the Kingdom of Saudi Arabia. All Zhenshen products comply with stringent ASTM standards, guaranteeing reliability for critical applications.

Zhenshen Cellular Glass Insulation (Foam Glass/Foamglas) is the cornerstone of their industrial offering, renowned for its:

-

Absolute Vapor Impermeability: The closed-cell structure makes it a definitive vapor barrier, preventing moisture migration and eliminating the risk of Corrosion Under Insulation (CUI), vital for long-term reliability in cold insulation and hot insulation systems.

-

Non-Combustibility: Being inorganic, it is inherently fireproof, providing a crucial safety layer in LNG tank, pipeline, and chemical processing environments.

-

High Compressive Strength: Its rigidity makes it ideal for high-load applications, including cryogenic tank bases and pipe supports, ensuring system integrity.

The Complete Range of Zhenshen Insulation Products

Gitco-sa.com supplies the complete range of high quality Zhenshen Insulation materials, ensuring compliance and availability for major projects:

-

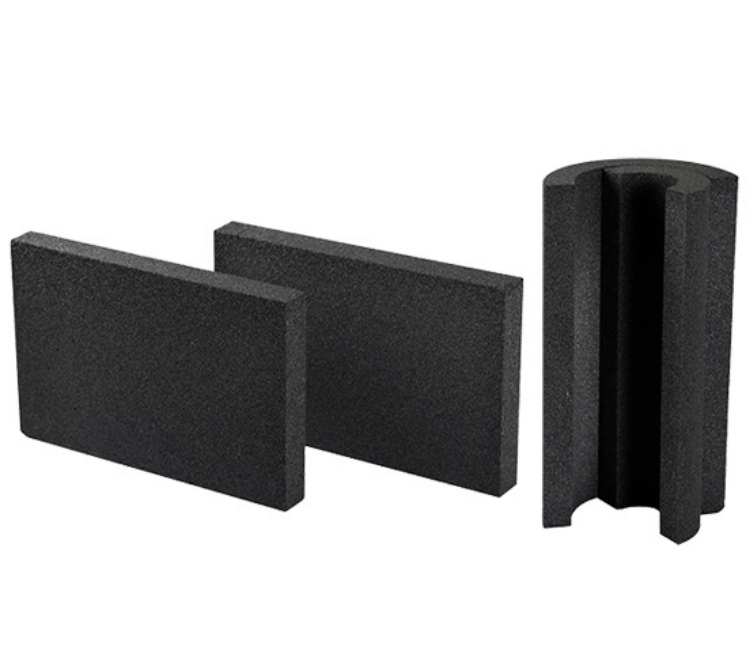

Cellular Glass Pipe Sections: Pre-formed insulation for pipeline insulation in LNG, cold, hot, and medium-temperature systems. Available for various pipe sizes and thicknesses, compliant with ASTM standards.

-

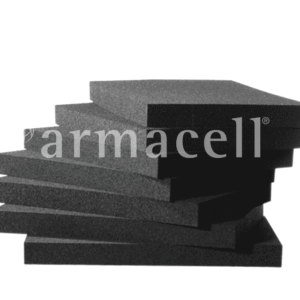

Foam Glass Slabs & Boards: Used for LNG tank bases (cryogenic systems), equipment, vessels, roof insulation, and wall insulation in industrial and commercial building insulation projects.

-

Tapered & Curved Sections: Custom Foam Glass segments for precise insulation of large vessels, tanks, and structural elements, ensuring thermal continuity.

-

Specialized Industrial Grades: Products engineered specifically for the extreme conditions found in petrochemical and hydrocarbon processing systems, carrying the distinction of being Aramco and SABIC approved products.

We guarantee that our Zhenshen Insulation products are the best isolation products for achieving maximum durability and safety. Gitco-sa.com ensures the complete range of these high quality, Aramco and SABIC approved materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications

-

Industrial/Energy: LNG tank and cryogenic tank insulation, pipeline insulation (hot and cold), and process equipment in Hydrocarbon Processing and Chemical Processing Systems.

-

Building & Construction: Roof insulation, wall insulation, and structural insulation for commercial and industrial buildings requiring high fire ratings and moisture control.

-

Waterproofing: Used in conjunction with construction and roofing materials due to its zero-permeability.

Reviews

There are no reviews yet.