Fiberglass Pipe Insulation for Industrial Heating Systems in Saudi Arabia

Fiberglass pipe insulation is a reliable solution for industrial heating systems, offering excellent thermal efficiency, energy savings, and protection against heat loss and surface burns in process industries across Saudi Arabia.

Description

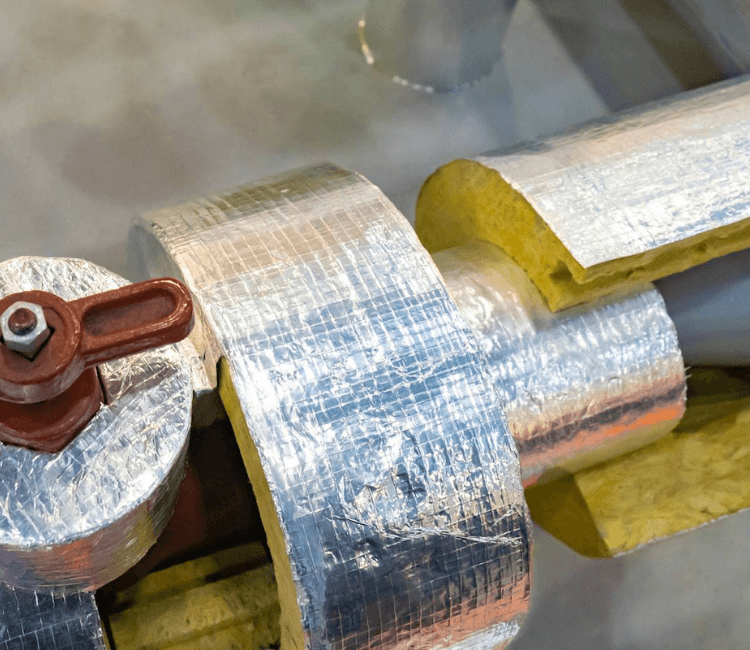

Fiberglass pipe insulation is widely used in industrial heating systems and process industries to maintain precise temperature control, improve energy efficiency, and enhance workplace safety. Designed to withstand high operating temperatures, fiberglass insulation minimizes heat loss while protecting personnel from hot piping surfaces.

At Gitco-sa.com, we supply a complete range of fiberglass pipe insulation solutions suitable for refineries, petrochemical plants, power stations, manufacturing facilities, and commercial HVAC systems across Saudi Arabia.

Why Fiberglass Pipe Insulation Is Essential

In process industries, uninsulated or poorly insulated pipes can lead to:

-

Significant energy losses

-

Increased operational costs

-

Risk of burns and workplace injuries

-

Reduced equipment lifespan

Fiberglass pipe insulation acts as a thermal barrier, ensuring stable system performance even under demanding industrial conditions.

Know more about Pipe Insulation:

- What is Fiberglass Pipe Insulation?

It is a rigid, pre-formed insulation product, molded from heavy-density, resin-bonded inorganic glass fibers to fit specific pipe diameters. - What is the standard format for this insulation?

It is typically supplied in 3-foot (approx. 91.4 cm) long, hinged sections that open to easily snap around the pipe. - What is the purpose of the resin binder used in the manufacturing process?

The thermoset resin binder holds the glass fibers together, giving the insulation its molded shape and rigidity (heavy density). - What is the common facing or jacketing used on fiberglass pipe insulation?

The most common facing is the All Service Jacket (ASJ), which is a white paper/foil/film laminate that acts as a vapor barrier and has a self-sealing adhesive lap (SSL). - Is the fiberglass material combustible?

No, the base glass fiber material is non-combustible and contributes to the insulation’s excellent fire safety ratings (Flame Spread Index ≤ 25, Smoke Developed Index ≤ 50). - What is the maximum operating temperature for Fiberglass Pipe Insulation?

High-density industrial grades can withstand continuous service temperatures up to 1,000°F (538 °C), making it ideal for steam and high-temperature process lines. - Can it be used on cold or chilled water pipes?

Yes, it can be used on cold pipes down to 0°F (-18 °C), but the continuous integrity of the ASJ vapor barrier is critical to prevent condensation and moisture ingress. - What is the key application area where fiberglass pipe insulation is dominant?

It is the go-to choice for High-Temperature Hot Water (HTHW), steam lines, and condensate return lines in commercial and industrial HVAC and plumbing systems. - What are “Dual Temperature Systems” and is fiberglass suitable for them?

Dual temperature systems fluctuate between hot and cold conditions (e.g., HVAC lines). Fiberglass is suitable, but requires meticulous sealing of the vapor barrier to handle the cold-cycle condensation risk. - Is this insulation used in outdoor applications?

Yes, but the ASJ jacket requires protection with a weather-proof aluminum or PVC jacket (cladding) to protect the vapor barrier and insulation from UV light and water. - What is the typical thermal conductivity (λ) of fiberglass pipe insulation?

The λ value is low, generally around 0.034 W(m·K) at 25 °C mean temperature, providing good energy efficiency. - What does the R-value of pipe insulation depend on?

Unlike flat insulation, the R-value of pipe insulation depends on both the insulation thickness and the pipe size, due to the change in surface area. - How does the insulation prevent heat loss or gain?

The matrix of glass fibers traps millions of tiny air pockets, which resist the transfer of heat by conduction, convection, and radiation. - How does moisture affect the thermal performance of fiberglass?

Since fiberglass is an open-cell material, if the ASJ vapor barrier is compromised and the insulation gets wet, its R-value can be significantly reduced due to water replacing the trapped air. - What is the function of the ASJ self-sealing lap (SSL)?

The SSL is a factory-applied adhesive strip that secures the jacket overlap after installation, creating a continuous vapor retarder along the length of the pipe section - What standard governs the dimensional requirements of the insulation?

The inner and outer dimensions are typically specified by ASTM C585 to ensure a proper fit over standard pipe sizes (NPS) and copper tubing sizes (CTS). - How are the circumferential and butt joints sealed?

The butt joints (where two 3-foot sections meet) are sealed using a matching butt strip tape (ASJ tape) supplied by the manufacturer, ensuring vapor seal continuity. - What is required to insulate pipe fittings (elbows, tees)?

Fittings require specialized fabrication (cutting and mitering the pipe insulation into segments) or the use of pre-molded PVC fitting covers that are filled with loose-fill fiberglass or mastic.

Reviews

There are no reviews yet.