AF/ArmaFlex: Flexible Insulation with Antimicrobial Protection

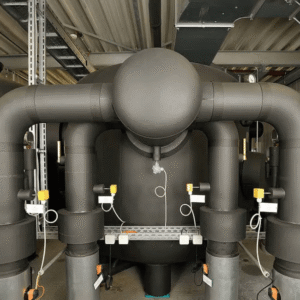

AF/ArmaFlex: Highly flexible, closed-cell insulation with built-in Microban antimicrobial protection, high water vapor diffusion resistance, and low thermal conductivity. Available at Gitco-sa.com (authorized Armacell distributor in Saudi Arabia & Bahrain).

Description

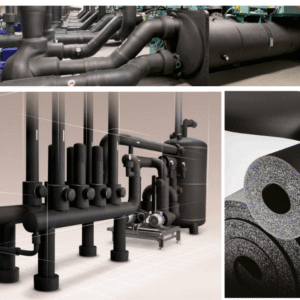

AF/ArmaFlex is the first choice for professional insulation, offering a highly flexible, closed-cell structure with exceptional performance characteristics. This reliable insulation material boasts high resistance to water vapor diffusion, low thermal conductivity for efficient energy saving, and built-in Microban antimicrobial protection to inhibit the growth of mold and mildew. In Saudi Arabia and Bahrain, gitco-sa.com is a trusted authorized distributor of Armacell products, including AF/ArmaFlex.

The flexibility of AF/ArmaFlex ensures easy and quick installation, even in tight spaces and around complex fittings, ultimately increasing the equipment lifecycle. Its reliable condensation control properties prevent moisture-related issues and the potential for corrosion under insulation (CUI). A 10-year System Warranty may be possible, further highlighting the product’s durability and reliability.

Key Features of AF/ArmaFlex:

- Highly Flexible: Easy to install in various applications.

- Closed-Cell Structure: Provides excellent resistance to water vapor diffusion (μ ≥ 10,000 for most sizes, μ ≥ 7,000 for larger sizes).

- Low Thermal Conductivity: Minimizes energy loss (λd ≤ 0.033 W/(m·K) for most sizes, λd ≤ 0.036 W/(m·K) for larger sizes at 0°C).

- Built-in Microban Antimicrobial Protection: Inhibits the growth of mold and mildew.

- Reliable Condensation Control: Prevents moisture-related damage.

- Self-Extinguishing: Does not drip or spread flames in case of fire.

- FM Approved: Meets recognized safety standards.

- UL 94 5VA/5VB Pass: Meets stringent flammability requirements for certain thicknesses.

- Reduces Structure-Borne Sound Transmission: Contributes to a quieter environment (≤ 28 dB(A)).

- Low VOC Content: Contributes to good indoor air quality.

Product Variations of AF/ArmaFlex:

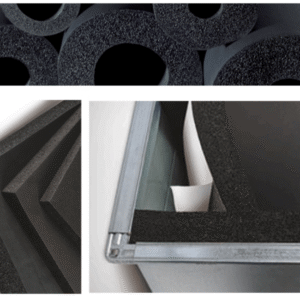

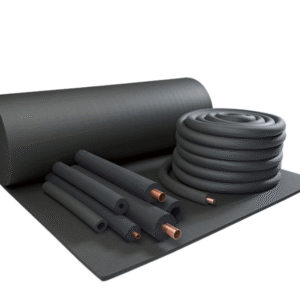

AF/ArmaFlex is available in a wide range of variations to suit diverse application needs:

- Tubes (AF-1 to AF-6): Available in various thicknesses (ranging from thinner options like AF-1 to thicker options like AF-6) and inner diameters to fit different pipe sizes.

- Sheets (AF-03MM to AF-50MM): Available in various thicknesses (from thin 3mm sheets up to thicker 50mm sheets) and standard roll widths.

- Self-Adhesive Tubes: Feature a pressure-sensitive adhesive coating for faster installation.

- Self-Adhesive Sheets: Feature a pressure-sensitive adhesive backing for easy application on flat or curved surfaces.

- Tapes: Insulation tapes for sealing joints and seams.

- Strips: Narrower rolls for specific applications.

- Tube – standard. Black. 2.0m length, AF-1: AF-1-006, AF-1-008, AF-1-010, AF-1-012, AF-1-015, AF-1-018, AF-1-022, AF-1-025, AF-1-028, AF-1-030, AF-1-032, AF-1-035, AF-1-038, AF-1-042, AF-1-045, AF-1-048, AF-1-054, AF-1-057, AF-1-060, AF-1-064, AF-1-070, AF-1-076, AF-1-080, AF-1-089 , AF-1-102, AF-1-108, AF-1-110, AF-1-114 , AF-1-125, AF-1-140, AF-1-160

- Tube – standard. Black. 2.0m length, AF-2: AF-2-006, AF-2-008, AF-2-010, AF-2-012, AF-2-018, AF-2-022, AF-2-025, AF-2-028, AF-2-030 , AF-2-032, AF-2-035, AF-2-040, AF-2-042, AF-2-048, AF-2-050, AF-2-054, AF-2-057, AF-2-060, AF-2-064, AF-2-070, AF-2-076, AF-2-080, AF-2-089, AF-2-102, AF-2-108, AF-2-110, AF-2-114, AF-2-125 , AF-2-133, AF-2-140, AF-2-160

- Tube – standard. Black. 2.0m length, AF-3: AF-3-010, AF-3-012, AF-3-015, AF-3-018, AF-3-022, AF-3-028 , AF-3-035, AF-3-042, AF-3-048, AF-3-054, AF-3-060, AF-3-064, AF-3-070, AF-3-076, AF-3-089, AF-3-108, AF-3-108, AF-3-110, AF-3-114, AF-3-125 , AF-3-133, AF-3-140 , AF-3-160

- Tube – standard. Black. 2.0m length, AF-4: AF-4-006, AF-4-010, AF-4-012, AF-4-015, AF-4-018 , AF-4-022, AF-4-025, AF-4-028, AF-4-030, AF-4-032, AF-4-035, AF-4-040, AF-4-042, AF-4-045, AF-4-048, AF-4-050, AF-4-054, AF-4-057, AF-4-060, AF-4-064, AF-4-070, AF-4-076, AF-4-080, AF-4-089, AF-4-102, AF-4-108, AF-4-110, AF-4-114, AF-4-125, AF-4-133 , AF-4-140, AF-4-160, AF-4-168

- Tube – standard. Black. 2.0m length, AF-5 : AF-5-015, AF-5-018, AF-5-020, AF-5-022 , AF-5-025, AF-5-028, AF-5-030, AF-5-032, AF-5-035, AF-5-042, AF-5-048, AF-5-054, AF-5-060, AF-5-066, AF-5-070, AF-5-076, AF-5-089, AF-5-108, AF-5-114, AF-5-125, AF-5-140, AF-5-168

- Tube – standard. Black. 2.0m length, AF-6: AF-6-010, AF-6-012, AF-6-015, AF-6-018, AF-6-022, AF-6-028, AF-6-035, AF-6-042, AF-6-048, AF-6-054, AF-6-057, AF-6-060,AF-6-064, AF-6-070, AF-6-076,AF-6-089, AF-6-102, AF-6-108, AF-6-114, AF-6-125 , AF-6-133, AF-6-140, AF-6-160, AF-6-168

- Tube – self-seal. Black. 2.0m length, AF-1 : AF-1-012-A, AF-1-015-A, AF-1-018-A, AF-1-018-A, AF-1-022-A, AF-1-028-A, AF-1-030-A , AF-1-035-A, AF-1-042-A, AF-1-048-A, AF-1-054-A, AF-1-076-A, AF-1-089-A

- Tube – self-seal. Black. 2.0m length, AF-2: AF-2-012-A, AF-2-015-A, AF-2-018-A, AF-2-022-A, AF-2-028-A, AF-2-030-A , AF-2-042-A, AF-2-048-A, AF-2-054-A, AF-2-060-A , AF-2-064-A, AF-2-070-A, AF-2-076-A, AF-2-089-A

- Tube – self-seal. Black. 2.0m length, AF-3: AF-3-015-A, AF-3-018-A, AF-3-022-A, AF-3-028-A, AF-3-035-A, AF-3-042-A , AF-3-048-A , AF-3-054-A, AF-3-060-A, AF-3-076-A, AF-3-089-A

- Tube – self-seal. Black. 2.0m length, AF-4: AF-4-015-A, AF-4-018-A, AF-4-022-A , AF-4-028-A, AF-4-035-A, AF-4-042-A, AF-4-048-A, AF-4-054-A, AF-4-060-A, AF-4-064-A, AF-4-070-A, AF-4-076-A , AF-4-089-A

- Coil. Black, AF-1: AF-1-006/E, AF-1-008/E, AF-1-010/E, AF-1-012/E, AF-1-015/E, AF-1-018/E, AF-1-018/E, AF-1-022/E, AF-1-028/E

- Coil. Black, AF-2: AF-2-006/E, AF-2-008/E, AF-2-010/E, AF-2-012/E , AF-2-015/E, AF-2-018/E, AF-2-022/E, AF-2-028/E

- Sheet – standard. Black: AF-10MM, AF-13MM, AF-16MM, AF-19MM, AF-25MM, AF-50MM

- Sheet – self-adhesive. Black: AF-10MM/A, AF-13MM/A, AF-19MM/A, AF-25MM/A , AF-32MM/A, AF-50MM/A

- Roll – standard. Black: AF-03MM/E, AF-10MM/E, AF-13MM/E, AF-16MM/E, AF-19MM/E, AF-25MM/E, AF-32MM/E, AF-50MM/E

- Roll – standard self-adhesive. Black: AF-03MM/EA, AF-06MM/EA, AF-10MM/EA, AF-13MM/EA, AF-16MM/EA, AF-19MM/EA, AF-25MM/EA, AF-32MM/EA, AF-50MM/EA

- Tape – insulation. Black: AF-TAPE-MC, AF-TAPE-MC/6

- Strips – self-adhesive. Black: AF-10MM/E-S100, AF-10MM/E-S50, AF-13MM/E-S100, AF-13MM/E-S50, AF-19MM/E-S50, AF-19MM/E-S100, AF-19MM/E-S75

ArmaFix AF. Pipe support – combi pack. Pipe support and a suitable clamp designed for use with AF/ArmaFlex.

- AF-2 (insulation thickness: 9.5mm – 16.0mm): FX-2-10/12K, FX-2-15/18K , FX-2-22/25K , FX-2-28/30K, FX-2-35/38K, FX-2-42/45K , FX-2-48K, FX-2-54/57K, FX-2-60/64K, FX-2-70K, FX-2-76/80K, FX-2-89K

- AF-4 (AF-3)* (insulation thickness 15.5 mm – 22.5 mm): FX-4(3)-10/12K, FX-4(3)-15/18K, FX-4(3)-22/25K , FX-4(3)-28/30K, FX-4(3)-35/38K, FX-4(3)-42/45K, FX-4(3)-48K, FX-4(3)-54/57K, FX-4(3)-60/64K, FX-4(3)-70K, FX-4(3)-76/80K, FX-4(3)-89K

ArmaFix AF. Pipe support – combi pack. Pipe support and a suitable clamp designed for use with AF/ArmaFlex.

- AF-6 (insulation thickness: 32.0mm – 45.0mm): FX-6-15/18K, FX-6-22/25K, FX-6-28/30K, FX-6-35/38K, FX-6-42/45K, FX-6-48K, FX-6-54/57K, FX-6-60/64K, FX-6-70K, FX-6-76/80K, FX-6-89K

ArmaFix AF. Pipe support – combi pack. Pipe support and a suitable clamp designed for use with AF/ArmaFlex.

- AF-6 (insulation thickness: 32.0mm – 45.0mm)

- ArmaFix AF. Pipe support – donut type: FX-2-10/12, FX-2-15/18, FX-2-22/25, FX-2-28/30, FX-2-35/38, FX-2-42/45, FX-2-48, FX-2-54/57, FX-2-60/64, FX-2-70, FX-2-76/80, FX-2-89, FX-2-102/108, FX-2-110/114, FX-2-125, FX-2-133/140, FX-2-160, FX-2-165/168

ArmaFix AF. Pipe support – donut type

- AF-4 (AF-3)* (insulation thickness 15.5 mm – 22.5 mm): FX-4(3)-10/12, FX-4(3)-15/18, FX-4(3)-22/25, FX-4(3)-28/30, FX-4(3)-35/38, FX-4(3)-42/45, FX-4(3)-48, FX-4(3)-54/57, FX-4(3)-60/64, FX-4(3)-70 , FX-4(3)-76/80, FX-4(3)-89, FX-4(3)-102/108, FX-4(3)-110/114, FX-4(3)-125, FX-4(3)-133/140 , FX-4(3)-160, FX-4(3)-165/168, FX-4(3)-204, FX-4(3)-216/219 , FX-4(3)-225, FX-4(3)-254, FX-4(3)-267/273, FX-4(3)-280, FX-4(3)-306, FX-4(3)-324, FX-4(3)-356 , FX-4(3)-406, FX-4(3)-457, FX-4(3)-508, FX-4(3)-610

ArmaFix AF. Pipe support – donut type

- AF-6 (insulation thickness: 32.0mm – 45.0mm): FX-6-10/12, FX-6-15/18, FX-6-22/25, FX-6-28/30, FX-6-35/38, FX-6-42/45, FX-6-48, FX-6-54/57, FX-6-60/64, FX-6-70, FX-6-76/80, FX-6-89, FX-6-102/108, FX-6-110/114, FX-6-125, FX-6-133/140, FX-6-160, FX-6-165/168, FX-6-204, FX-6-216/219, FX-6-254, FX-6-267/273, FX-6-306, FX-6-324, FX-6-356, FX-6-406, FX-6-457, FX-6-508, FX-6-610, FX-6-711,

- ArmaFix AF. Duct support: AS-13MM, AS-19MM, AS-25MM, AS-32MM, AS-50MM

Please contact Gitco-sa.com for detailed information on specific part numbers, dimensions, and availability of AF/ArmaFlex variations in Saudi Arabia and Bahrain to meet your exact project requirements. The thermal conductivity values may vary slightly depending on the specific thickness and product range (AF-1 to AF-4 vs. AF-5 to AF-6 and thicker sheets).

Applications of AF/ArmaFlex:

- Residential Buildings

- Thermal Insulation

- Commercial Buildings

- Industrial Facilities

- OEM (Original Equipment Manufacturer)

- Transportation

- HVAC (Heating, Ventilation, and Air Conditioning)

- Refrigeration Systems

AF/ArmaFlex – Frequently Asked Questions

AF/ArmaFlex is a widely recognized and trusted flexible elastomeric foam insulation material:

-

What is AF/ArmaFlex?

AF/ArmaFlex is a highly flexible, closed-cell elastomeric foam insulation material made from synthetic rubber (NBR). It’s designed for reliable condensation control and energy efficiency in various applications. -

What are the key characteristics of AF/ArmaFlex?

Key characteristics include a closed-cell structure, high resistance to water vapor diffusion, low thermal conductivity, and built-in Microban® antimicrobial protection. -

What is the primary use of AF/ArmaFlex?

Its primary use is for insulation and protection against condensation and energy loss on pipes, air ducts, vessels, and other equipment in HVAC-R and industrial systems. -

Does AF/ArmaFlex have a built-in vapor barrier?

Yes, its closed-cell structure provides a high resistance to water vapor transmission (µ ≥ 10,000), effectively acting as a built-in vapor barrier. -

What is the thermal conductivity (λ) of AF/ArmaFlex?

AF/ArmaFlex has a low thermal conductivity, typically ≤ 0.033 W/(m·K) at 0°C for tubes (6-19mm) and sheets/tapes (3-32mm). -

What is the service temperature range of AF/ArmaFlex?

The service temperature range is from -50°C to +110°C (up to +85°C for glued sheets or tapes). -

What is Microban® protection in AF/ArmaFlex?

AF/ArmaFlex is the first flexible insulation material equipped with Microban® antimicrobial technology, inhibiting the growth of mold and bacteria. -

What is the fire performance classification of AF/ArmaFlex?

AF/ArmaFlex tubes generally achieve a Euroclass BL-s3, d0, while sheets and tapes achieve B-s3, d0 according to EN 13501-1. It also meets Class 1 surface spread of flame (BS 476 Part 7). -

Is AF/ArmaFlex self-adhesive?

Yes, AF/ArmaFlex is available in self-adhesive tubes and sheets with a pressure-sensitive adhesive coating for easier and faster installation. -

What are the benefits of using AF/ArmaFlex in HVAC-R systems?

It prevents condensation, reduces energy losses, inhibits microbial growth, and offers reliable long-term performance, contributing to energy efficiency and system longevity. -

Can AF/ArmaFlex be used in industrial applications?

Yes, it is suitable for various industrial applications, including process piping, to prevent condensation, save energy, and protect equipment. -

Is AF/ArmaFlex resistant to oils and chemicals?

AF/ArmaFlex offers good resistance to many common industrial oils and chemicals. Refer to the technical datasheet for specific chemical compatibility. -

Does AF/ArmaFlex contribute to noise reduction?

Yes, the flexible, closed-cell structure of AF/ArmaFlex helps to reduce structural noise transmission in service water and wastewater installations. -

What is the lifespan of AF/ArmaFlex?

When installed correctly and protected from extreme UV exposure (if outdoors), AF/ArmaFlex provides long-lasting thermal and condensation control. -

What are ArmaFix AF pipe supports, and how do they relate to AF/ArmaFlex?

ArmaFix AF pipe supports are specifically designed to be used with AF/ArmaFlex to prevent thermal bridges at pipe support locations, ensuring the continuity of the insulation system. -

Is AF/ArmaFlex environmentally friendly?

AF/ArmaFlex has a Zero Ozone Depletion Potential (ODP) and a low Global Warming Potential (GWP). It can also contribute to green building certifications. -

What are the different forms of AF/ArmaFlex available?

It is available in tubes (including self-seal options), sheets, rolls, and tapes to suit various application needs. -

How should AF/ArmaFlex be stored?

Self-adhesive products should be stored for no more than one year in dry, clean conditions at recommended temperatures to maintain adhesive properties. -

Where can I find the technical datasheet for AF/ArmaFlex?

The technical datasheet with detailed specifications and performance data is available on the Armacell website and potentially on Gitco-sa.com’s product page. -

Why is AF/ArmaFlex considered a reliable choice for insulation?

With over 40 years of trusted performance, its combination of low thermal conductivity, high water vapor resistance, fire safety properties, and built-in antimicrobial protection makes it a reliable and long-term solution for insulation needs.

Choose AF/ArmaFlex from Gitco-sa.com, your authorized Armacell distributor in Saudi Arabia and Bahrain, for a reliable, high-performance insulation solution with built-in antimicrobial protection.

Brand

Armacell

| Property | Value / Assessment | Standard / Test method | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Temperature range | ||||||||||

| Service temperature |

|

EN 14706, EN 14707, EN 14304 | ||||||||

| Thermal conductivity | ||||||||||

| Declared thermal conductivity |

|

EN ISO 13787, EN 12667, EN ISO 8497 | ||||||||

| Declared thermal conductivity |

|

EN ISO 13787, EN 12667, EN ISO 8497 | ||||||||

| Fire Performance and Approvals | ||||||||||

| Reaction to fire | Tubes: B(L)-s3, d0 Sheets: B-s3, d0 Tapes: B-s3, d0 |

EN 13501-1, EN ISO 11925-2, EN 13823 | ||||||||

| Surface flammability | low-flammable – 2010 FTP-Code (MED 96/98/EC, Module D) | IMO 2010 FTP Code, Part 53 | ||||||||

| FM approved | 4924 – Pipe and Duct Insulation | UBC26-3 | ||||||||

| Passive fire protection | ||||||||||

| Fire resistance of elements of construction | EI 30 – EI 90 | EN 13501-2, EN 1366-3 | ||||||||

| UL standards | ||||||||||

| UL 94 5VA4 | Pass (tubes ≥ 3.0 mm) Pass (sheets ≥ 4.2 mm) |

UL 94, IEC 60695-11-10, UL 746B | ||||||||

| UL 94 5VB4 | Pass (sheets 3 mm < 4.2 mm) | UL 94, IEC 60695-11-10, UL 1191, UL 746B | ||||||||

| Fire performance | ||||||||||

| Practical fire behaviour | Self-extinguishing, does not drip, does not spread flames | |||||||||

| Resistance to water vapour | ||||||||||

| Water vapour diffusion resistance factor | Sheets (AF-03MM to AF-32MM) and tubes (AF-1 to AF-4): μ ≥ 10,000 Sheets (AF-50MM) and tubes (AF-5 to AF-6): μ ≥ 7,000 |

EN 12086, EN 13469 | ||||||||

| Physical attributes | ||||||||||

| Dimensions and tolerances | in accordance with EN 14304, table 1 | EN 822, EN 823, EN 13467 | ||||||||

| Acoustic performance | ||||||||||

| Reduction of structure-borne sound transmission | ≤ 28 dB (A) | EN ISO 3822-1 | ||||||||

| Weather and UV resistance | ||||||||||

| UV resistance5 | Protection against UV radiation is necessary (see Technical Bulletin no. 142). | |||||||||

| Health and environment | ||||||||||

| Antimicrobial behaviour | Built-in Microban active antimicrobial protection: No fungal growth observed | EN ISO 846, VDI 6022 | ||||||||

| Environmental Product Declaration (EPD) | Type III Environmental Product Declaration (EPD): Declaration number “EPD-ARM-20200219-IBB1-EN”, Institut Bauen und Umwelt e.V. (IBU) | ISO 14025, EN 15804+A2 | ||||||||

| Other technical features | ||||||||||

| Shelf life | Self-adhesive tapes, self-adhesive sheets, self-adhesive tubes, strips: 1 year | |||||||||

| Storage | Can be stored in dry, clean rooms at normal relative humidity (50% – 70%) and ambient temperature (0 °C –35 °C). | |||||||||

|

1For use in temperatures beyond the maximum and minimum service temperature range indicated in the technical data table, please contact our Customer Service Centre. 2+85 °C, for products with a self-adhesive layer. 3According to IMO 2010 FTP Code annex 2, clause 2.2 a fire technical test for smoke density and toxicity is not necessary. 4Only for products without self-adhesive-layer. 5If ArmaFlex is used outdoors or in applications under UV radiation, it should be protected with ArmaFinish Paint, or a covering such as ArmaClad Arma-Chek within 3 days of installation. |

||||||||||

Reviews

There are no reviews yet.