ArmaFlex Ultima C: Pre-Covered, High Fire Safety Insulation

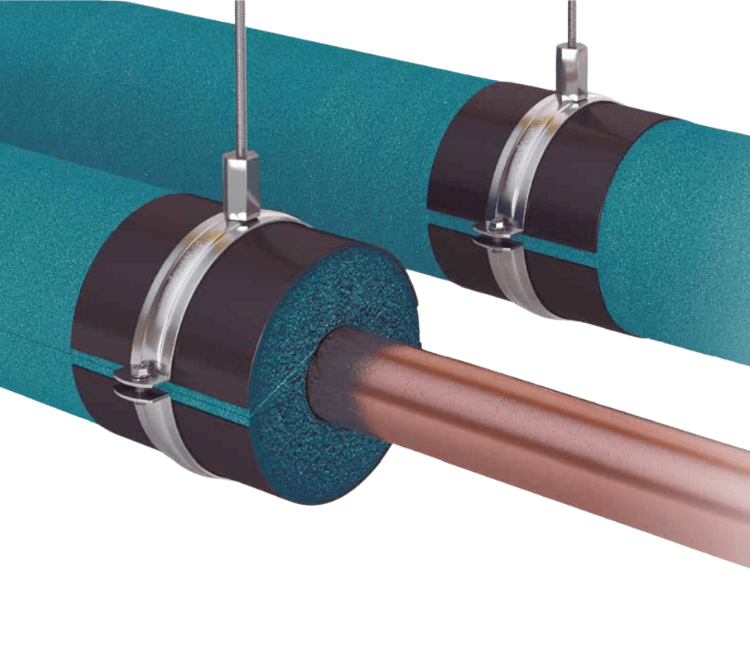

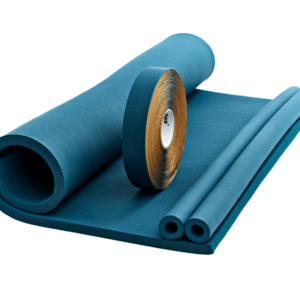

ArmaFlex Ultima C: Pre-covered insulation sheets offering the highest level of fire safety (B-s1,d0), low smoke generation, and excellent UV resistance. re-covered elastomeric foam on the basis of a patented synthetic rubber composition with improved fire retardant properties, low smoke generation, and a closed-cell material structure, laminated with a functional intumescent covering. For use in HVAC, refrigeration, and process equipment applications. Available at Gitco-sa.com (authorized Armacell distributor in Saudi Arabia & Bahrain).

Description

ArmaFlex Ultima C represents the pinnacle of fire safety in flexible elastomeric foam insulation. This innovative product features the same patented synthetic rubber composition as ArmaFlex Ultima, known for its improved fire retardant properties and low smoke generation, now pre-covered with a functional intumescent covering. This unique combination provides the highest level of fire safety (B-s1,d0 classification) in a flexible insulation sheet, ideal for HVAC, refrigeration, and process equipment applications. Gitco-sa.com is a proud authorized distributor of Armacell products, including ArmaFlex Ultima C, in Saudi Arabia and Bahrain.

The ArmaPrene patented technology ensures a closed-cell material structure, providing excellent thermal insulation and resistance to water vapor ingress. The pre-applied intumescent covering enhances fire safety by expanding and charring when exposed to heat, further inhibiting flame spread and smoke production. ArmaFlex Ultima C is also free of dust, fibers, PVC, and bromine, contributing to improved indoor air quality and environmental responsibility. Its very high UV resistance ensures long-term performance even in exposed applications. When used with ArmaFlex Ultima ECO550 Adhesive, it meets the requirements for sustainable construction, including LEED certifications.

Key Features of ArmaFlex Ultima C:

- Highest Fire Safety: Achieves a B-s1,d0 reaction to fire classification.

- Pre-Covered: Features a functional intumescent covering for enhanced fire protection.

- Low Smoke Generation: Significantly reduces smoke density in case of fire.

- Patented ArmaPrene Technology: Ensures superior flexibility and performance.

- Closed-Cell Structure: Effectively prevents condensation and saves energy.

- Very High UV Resistance: Suitable for applications exposed to sunlight.

- Free of Dust and Fibers: Improves indoor air quality.

- PVC and Bromine Free: Environmentally responsible material composition.

- Sustainable Construction: Meets LEED requirements when used with ArmaFlex Ultima ECO550 Adhesive.

- Excellent Thermal Conductivity: Declared thermal conductivity Θm ≤ 0.040 W/(m·K) at 0 °C and ≤ 0.045 W/(m·K) at 40 °C.

- Self-Extinguishing: Does not drip or spread flames, with an intumescent coating that chars in fire.

Product Variations of ArmaFlex Ultima C:

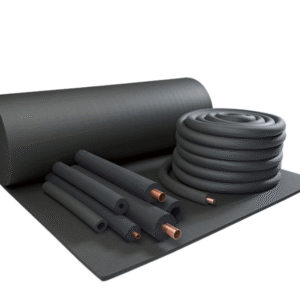

ArmaFlex Ultima C is primarily available in sheets (rolls) to cover larger surface areas. While the provided data doesn’t specify exact dimensions and part numbers, variations typically include:

- Different Thicknesses: To meet various thermal insulation requirements. Common thicknesses for ArmaFlex sheets range from 6mm up to 32mm.

- Roll Widths and Lengths: Standard roll dimensions are usually available, but specific sizes may vary.

- Self-Adhesive Options: Some variations might include a self-adhesive backing for easier installation.

Please contact Gitco-sa.com for detailed information on available thicknesses, roll sizes, and self-adhesive options for ArmaFlex Ultima C sheets in Saudi Arabia and Bahrain to suit your specific project needs.

Applications of ArmaFlex Ultima C :

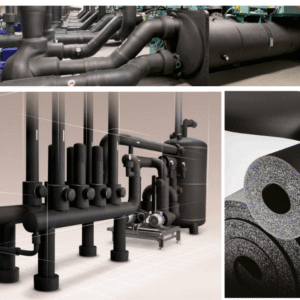

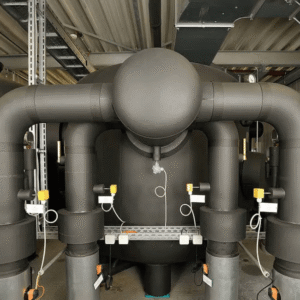

- HVAC (Heating, Ventilation, and Air Conditioning) ducts and equipment

- Refrigeration systems

- Process equipment

- Commercial buildings with stringent fire safety regulations

- Industrial facilities where fire safety is paramount

- Applications requiring UV resistance

ArmaFlex Ultima C – Frequently Asked Questions :

ArmaFlex Ultima C is a pre-covered, flexible elastomeric foam insulation renowned for its exceptional fire safety characteristics and suitability for various HVAC-R and industrial applications. Here are 20 frequently asked questions about ArmaFlex Ultima C:

-

What is ArmaFlex Ultima C?

ArmaFlex Ultima C is a pre-covered, closed-cell flexible elastomeric foam insulation based on Armacell’s patented ArmaPrene® technology, featuring an intumescent covering for enhanced fire protection. -

What makes ArmaFlex Ultima C different from standard ArmaFlex Ultima?

The key difference is the integrated, functional intumescent covering on ArmaFlex Ultima C, which provides increased protection against mechanical impact and makes it easy to clean, while also reinforcing the vapor barrier. -

What is the fire classification of ArmaFlex Ultima C?

ArmaFlex Ultima C achieves a Euroclass B-s1,d0 fire classification, indicating very limited contribution to fire, very low smoke production, and no flaming droplets. This is a high fire safety standard for flexible technical insulation sheets. -

Why is the Euroclass B-s1,d0 fire rating important?

This rating signifies a high level of fire safety, crucial for protecting lives and property by limiting flame spread and significantly reducing smoke development, improving visibility during evacuation. -

What is the ArmaPrene® technology in ArmaFlex Ultima C?

ArmaPrene® is Armacell’s patented synthetic rubber composition that enables ArmaFlex Ultima products to achieve a unique combination of high fire resistance with minimal smoke generation, without the use of brominated flame retardants. -

What are the primary benefits of using ArmaFlex Ultima C?

Key benefits include superior fire safety performance (B-s1,d0), enhanced protection against mechanical impact, ease of cleaning, reinforced water vapor barrier, reliable condensation control, and long-term energy savings. -

What is the thermal conductivity of ArmaFlex Ultima C? The declared thermal conductivity (λd) typically ranges from ≤ 0.039 W/(m·K) at 10°C to ≤ 0.044 W/(m·K) at 52°C, ensuring efficient thermal insulation.

-

What is the service temperature range of ArmaFlex Ultima C?

The service temperature range is generally from -50°C to +110°C. -

What is the water vapor diffusion resistance (µ) of ArmaFlex Ultima C?

ArmaFlex Ultima C has a high water vapor diffusion resistance factor (µ ≥ 10,000), effectively preventing moisture ingress and condensation. -

What are the typical applications for ArmaFlex Ultima C?

It is specifically engineered for insulation on air ducts, large pipe diameters, vessels, and tanks in commercial and industrial applications where improved fire performance is required. -

Is ArmaFlex Ultima C suitable for external applications?

Yes, ArmaFlex Ultima C is UV resistant according to EN ISO 4892-2, making it suitable for outdoor use. -

What forms does ArmaFlex Ultima C come in?

ArmaFlex Ultima C is available in sheets. -

Is ArmaFlex Ultima C easy to install?

Yes, the sheets are designed for straightforward installation on larger surfaces. -

What adhesives are recommended for ArmaFlex Ultima C?

Armacell recommends specific adhesives like ArmaFlex Ultima 700 and the solvent-free ArmaFlex Ultima SF990 for optimal performance and to meet green building scheme requirements. -

How does ArmaFlex Ultima C contribute to sustainability?

It meets the requirements for sustainable construction and is compatible with green building schemes like LEED, BREEAM, and DGNB, especially when used with ArmaFlex Ultima SF990 adhesive. -

How does ArmaFlex Ultima C compare to ArmaFlex AC Class O in terms of fire safety?

ArmaFlex Ultima C with its B-s1,d0 rating generally offers superior fire performance compared to ArmaFlex AC Class O, which has a Class O fire propagation rating (BS 476 Part 6) and a Class 1 surface spread of flame rating (BS 476 Part 7). Ultima C produces significantly less smoke. -

Does ArmaFlex Ultima C offer any acoustic benefits?

The dark-grey surface of ArmaFlex Ultima C is highly absorptive, and while primarily for thermal insulation and fire safety, it can contribute to some level of noise reduction. -

Is ArmaFlex Ultima C resistant to mechanical impact?

Yes, the intumescent covering provides a high level of protection against mechanical impact. -

Is ArmaFlex Ultima C easy to clean?

Yes, the pre-covered surface is designed to be easily cleanable. -

Where can I find more information or technical data about ArmaFlex Ultima C?

Detailed technical datasheets and product brochures are available on the Armacell website and potentially on Gitco-sa.com’s product page.

Choose ArmaFlex Ultima C from Gitco-sa.com for the highest level of fire safety in a flexible, pre-covered insulation sheet, available for your projects in Saudi Arabia and Bahrain.

Brand

Armacell

| Property | Value / Assessment | Standard / Test method | ||||||

|---|---|---|---|---|---|---|---|---|

| Temperature range | ||||||||

| Service temperature1 |

|

EN 14706, EN 14707, EN 14304 | ||||||

| Thermal conductivity | ||||||||

| Declared thermal conductivity |

|

EN ISO 13787, EN 12667, EN ISO 8497 | ||||||

| Fire Performance and Approvals | ||||||||

| Reaction to fire | B-s1,d0 | EN 13501-1, EN ISO 11925-2, EN 13823 | ||||||

| Fire performance | ||||||||

| Practical fire behaviour | Self-extinguishing, does not drip, does not spread flames, intumescent coating; very low smoke density | |||||||

| Physical attributes | ||||||||

| Dimensions and tolerances | in accordance with EN 14304, table 1 | EN 822, EN 823, EN 13467 | ||||||

| Weather and UV resistance | ||||||||

| UV resistance | Very high | EN ISO 4892-2 | ||||||

| Health and environment | ||||||||

| Environmental aspects | Meets the requirements for sustainable construction in combination with ArmaFlex Ultima ECO550 adhesive such as LEED. | |||||||

| Green building assessment | Meets the sustainable construction requirements for LEED v4.1, BREEAM international, WELL v2 and DGNB. | |||||||

| Additional features | SCCP, MCCP-free | |||||||

| Other technical features | ||||||||

| Adhesion and sealing | ArmaFlex Ultima ECO 550 and ArmaFlex Ultima 700 are the certified adhesives for this product. | |||||||

| Shelf life | Self-adhesive sheets, self-adhesive tape: 1 year | |||||||

| Storage | Can be stored in dry, clean rooms at normal relative humidity (50% to 70%) and ambient temperature (0 °C – 35 °C). | |||||||

|

1For use in temperatures beyond the maximum and minimum service temperature range indicated in the technical data table, please contact our Customer Service Centre. 2+85 °C, for products with a self-adhesive layer. |

||||||||

Datasheet

Reviews

There are no reviews yet.