ArmaFlex Ultima: Low Smoke, High Fire Safety Insulation

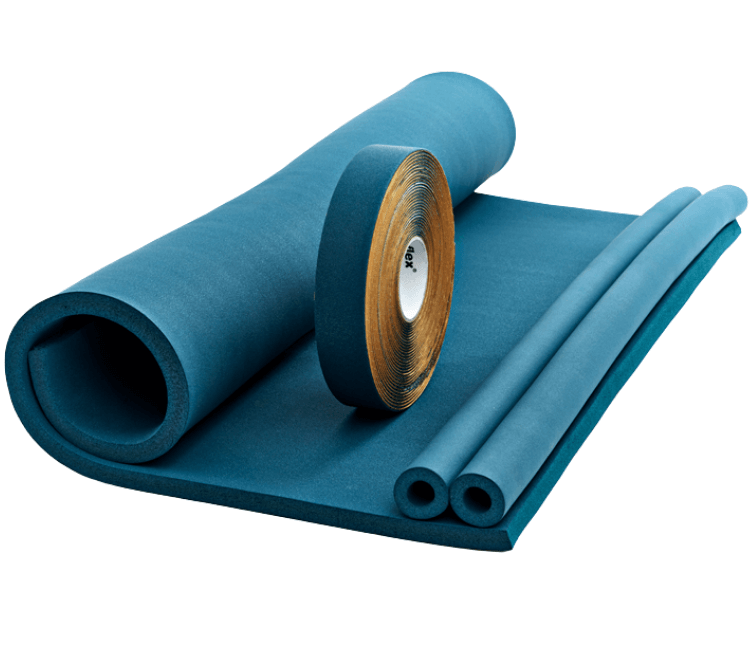

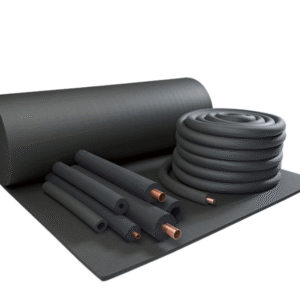

ArmaFlex Ultima, the first flexible insulation with low smoke emissions for improved fire safety, available at Gitco-sa.com (authorized Armacell distributor in Saudi Arabia & Bahrain). Ideal for HVAC, refrigeration, and industrial applications. Explore our range of tubes, sheets, and tapes for a complete, reliable insulation solution. Trust ArmaFlex Ultima for superior fire protection and energy efficiency.

Description

ArmaFlex Ultima is a revolutionary flexible elastomeric foam insulation based on Armacell’s patented ArmaPrene technology. Engineered with improved fire-retardant properties and exceptionally low smoke generation, ArmaFlex Ultima significantly enhances fire safety in HVAC, refrigeration, and process equipment applications. Its closed-cell material structure effectively prevents condensation and saves energy. Gitco-sa.com is a proud authorized distributor of Armacell products, including ArmaFlex Ultima, in Saudi Arabia and Bahrain.

ArmaFlex Ultima offers complete system integration with dedicated adhesives and ArmaFix Ultima pipe hangers. When combined with ArmaFlex Ultima ECO550 Adhesive, it meets the requirements for sustainable construction, including LEED certifications. This FM approved and IMO compliant insulation provides superior performance and peace of mind.

Key Features of ArmaFlex Ultima:

- Low Smoke Emissions: The best flexible insulation with low smoke density in case of fire.

- Improved Fire Safety: The first flexible insulation with low smoke emissions.

- Patented ArmaPrene Technology: Ensures superior performance and reliability.

- Complete System Integration: Compatible with ArmaFlex Ultima adhesives and ArmaFix Ultima hangers.

- Sustainable Construction: Meets LEED requirements when used with ArmaFlex Ultima ECO550 Adhesive.

- FM Approved: Certified for reliable performance.

- IMO Compliant: Meets fire safety standards for marine applications.

- Closed-Cell Structure: Effectively prevents condensation and saves energy.

- Wide Temperature Range: Service temperature from -50 °C to 110 °C.

- Excellent Thermal Conductivity: Declared thermal conductivity Θm ≤ 0.040 W/(m·K) at 0 °C and ≤ 0.045 W/(m·K) at 40 °C

- High Fire Performance: Reaction to fire B(L)-s1,d0 (tubes) and B-s2,d0 (sheets). Surface flammability is low-flammable according to IMO 2010 FTP Code.

- Self-Extinguishing: Does not drip or spread flames; very low smoke density in practical fire behavior.

- VOC Compliant: Fulfills all VOC requirements (French, Italian, Belgian, German AgBB, Blauer Engel, and Eurofins Indoor Air Comfort GOLD).

- Antimicrobial: No fungal growth observed.

- SCCP/MCCP-Free: Environmentally responsible formulation.

Product Variations of ArmaFlex Ultima:

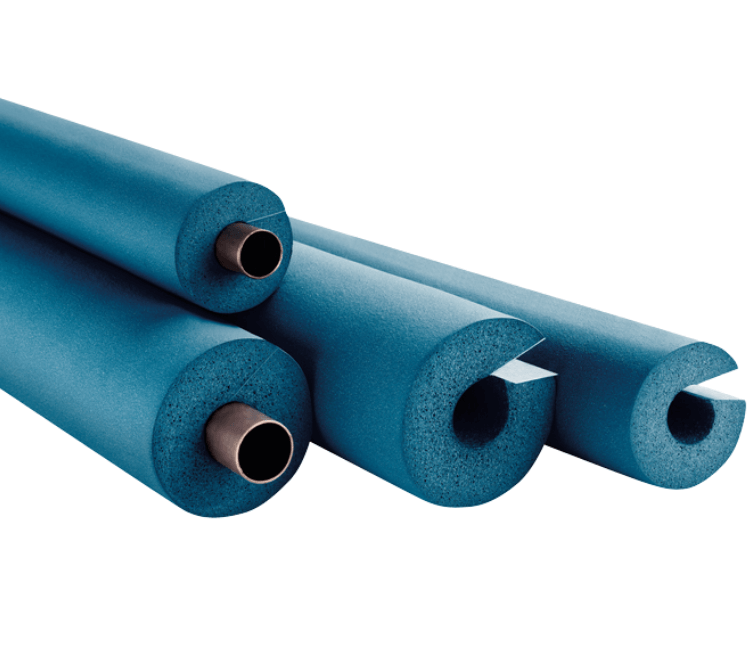

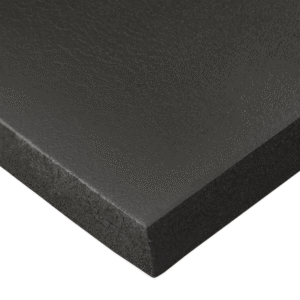

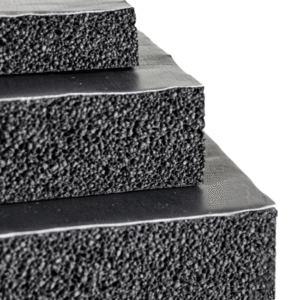

ArmaFlex Ultima is available in various forms to suit different applications:

- Tube – standard. Blue. Length: 2.0 m:9 mm: UD-09X012, UD-09X015, UD-09X018, UD-09X022, UD-09X028, UD-09X035, UD-09X042, UD-09X048, UD-09X054, UD-09X060, UD-09X064, UD-09X076 , UD-09X089.

- Tube – standard. Blue. Length: 2.0 m: 13 mm: UD-13X006, UD-13X010, UD-13X012, UD-13X015, UD-13X018, UD-13X022, UD-13X028, UD-13X035, UD-13X042, UD-13X048, UD-13X054, UD-13X060, UD-13X064, UD-13X076, UD-13X089, UD-13X114

- Tube – standard. Blue. Length: 2.0 m: 19 mm: UD-19X010, UD-19X012, UD-19X015, UD-19X018, UD-19X022, UD-19X028, UD-19X035, UD-19X042, UD-19X048, UD-19X054, UD-19X060, UD-19X064, UD-19X076, UD-19X089, UD-19X114

- Tube – standard. Blue. Length: 2.0 m: 25 mm: UD-25X015, UD-25X018, UD-25X022, UD-25X028 , UD-25X035, UD-25X042, UD-25X048 , UD-25X054, UD-25X060, UD-25X064, UD-25X076, UD-25X089, UD-25X114

- Tube – standard. Blue. Length: 2.0 m: 32 mm: UD-32X015, UD-32X018, UD-32X020, UD-32X022, UD-32X028, UD-32X035, UD-32X042, UD-32X048, UD-32X054, UD-32X060, UD-32X064, UD-32X076, UD-32X089, UD-32X114

- Tube – self-seal. Blue. Length: 2.0 m: 9 mm: UD-09X015-A, UD-09X018-A, UD-09X022-A, UD-09X028-A, UD-09X035-A, UD-09X042-A, UD-09X048-A, UD-09X054-A

- Tube – self-seal. Blue. Length: 2.0 m: 13 mm: UD-13X015-A, UD-13X018-A, UD-13X022-A, UD-13X028-A, UD-13X035-A, UD-13X042-A, UD-13X048-A, UD-13X054-A, UD-09X060-A, UD-09X076-A, UD-09X089-A, UD-13X060-A, UD-13X076-A, UD-13X089-A

- Tube – self-seal. Blue. Length: 2.0 m: 9 mm: UD-09X060-A, UD-09X076-A, UD-09X089-A

- Tube – self-seal. Blue. Length: 2.0 m: 13 mm: UD-13X060-A, UD-13X076-A, UD-13X089-A

- Tube – self-seal. Blue. Length: 2.0 m: 19 mm: UD-19X015-A, UD-19X018-A, UD-19X022-A, UD-19X028-A, UD-19X035-A, UD-19X042-A, UD-19X048-A, UD-19X054-A, UD-19X060-A, UD-19X076-A, UD-19X089-A

- Tube – self-seal. Blue. Length: 2.0 m: 25 mm: UD-25X018-A, UD-25X022-A, UD-25X028-A , UD-25X035-A, UD-25X042-A, UD-25X048-A, UD-25X054-A, UD-25X060-A, UD-25X076-A, UD-25X089-A,

- Tube – open. Blue: 9 mm: UD-09X300

- Tube – open. Blue: 13 mm: UD-13X300

- Tube – open. Blue: 19 mm: UD-19X300

- Tube – open. Blue: 25 mm: UD-25X300

- Tube – open. Blue: 25 mm: UD-32X300

- Roll – standard. Blue: UD-06-99/E, UD-09-99/E, UD-13-99/E, UD-19-99/E, UD-25-99/E, UD-32-99/E

- Roll – standard self-adhesive. Blue: UD-06-99/EA, UD-09-99/EA, UD-13-99/EA, UD-19-99/EA, UD-25-99/EA, UD-32-99/EA

- Tape – insulation. Blue: UD-TAPE

Please refer to the provided technical data for specific dimensions, tolerances, and packaging details for each variation. Gitco-sa.com offers the full range of ArmaFlex Ultima products to meet your specific insulation needs in Saudi Arabia and Bahrain.

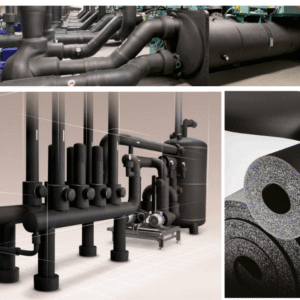

Applications:

- HVAC (Heating, Ventilation, and Air Conditioning)

- Refrigeration

- Process Equipment

- Commercial Buildings

- Industrial Facilities

- Transportation

- Residential Buildings

- Energy Sector

- OEM (Original Equipment Manufacturer)

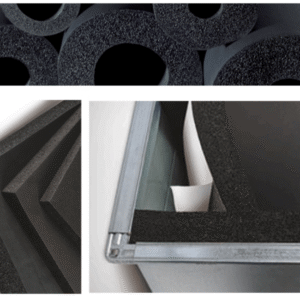

| Product Type | Thickness (mm) | Key Features |

| Standard Tubes | 9, 13, 19, 25, 32 | Flexible, closed-cell, low smoke, fire retardant, various pipe diameters |

| Self-Seal Tubes | 9, 13, 19, 25 | Flexible, closed-cell, low smoke, fire retardant, self-adhesive closure |

| Open Tubes | 9, 13, 19, 25, 32 | Flexible, closed-cell, low smoke, fire retardant, for post-installation |

| Standard Rolls | 6, 9, 13, 19, 25, 32 | Flexible sheets, closed-cell, low smoke, fire retardant, various widths |

| Self-Adhesive Rolls | 6, 9, 13, 19, 25, 32 | Flexible sheets, closed-cell, low smoke, fire retardant, self-adhesive backing |

| Insulation Tape | 3 | Flexible tape, closed-cell, low smoke, fire retardant, for sealing joints |

ArmaFlex Ultima – Frequently Asked Questions:

ArmaFlex Ultima is a cutting-edge flexible elastomeric foam insulation material known for its exceptional fire safety performance and other beneficial properties. Here are 20 frequently asked questions about ArmaFlex Ultima:

-

What is ArmaFlex Ultima? ArmaFlex Ultima is a flexible, closed-cell elastomeric foam insulation material based on Armacell’s patented ArmaPrene® technology. It’s designed for thermal insulation and condensation control in various applications.

-

What makes ArmaFlex Ultima unique? Its primary unique feature is its superior fire performance, achieving Euroclass BL-s1,d0, which signifies very low smoke density in case of fire, significantly less than standard elastomeric insulation.

-

What is the fire classification of ArmaFlex Ultima? ArmaFlex Ultima achieves Euroclass BL-s1,d0, the highest fire classification for flexible elastomeric insulation, indicating very limited contribution to fire, very low smoke production, and no flaming droplets.

-

Why is low smoke density important in insulation materials? Low smoke density improves visibility and air quality during a fire, providing more time for safe evacuation and reducing the risk of smoke inhalation, a major cause of fire-related fatalities.

-

What is ArmaPrene® technology? ArmaPrene® is a patented synthetic rubber composition developed by Armacell that allows ArmaFlex Ultima to achieve its unique combination of high fire resistance and minimal smoke development.

-

What are the key benefits of using ArmaFlex Ultima? Key benefits include exceptional fire safety (low smoke), reliable condensation control, long-term energy savings due to its low thermal conductivity, and contribution to sustainable building through compatibility with green building schemes.

-

What is the thermal conductivity of ArmaFlex Ultima? ArmaFlex Ultima exhibits a very good thermal conductivity (λ), typically around ≤ 0.040 W/(m·K) at 0°C and ≤ 0.045 W/(m·K) at 40°C, ensuring efficient insulation.

-

What is the service temperature range of ArmaFlex Ultima? The typical service temperature range for ArmaFlex Ultima is from -50 °C to +110 °C (up to +85 °C for fully glued sheets or tapes).

-

What is the water vapor diffusion resistance (µ) of ArmaFlex Ultima? ArmaFlex Ultima has a high water vapor diffusion resistance factor (µ ≥ 7,000), effectively preventing moisture ingress and condensation, which can lead to corrosion under insulation (CUI).

-

Is ArmaFlex Ultima suitable for sustainable construction? Yes, ArmaFlex Ultima meets the requirements for sustainable construction and is compatible with green building schemes like LEED, BREEAM, and DGNB, especially when used with ArmaFlex Ultima SF990 adhesive (solvent-free).

-

In what forms is ArmaFlex Ultima available? ArmaFlex Ultima is available in tubes, sheets, and self-adhesive versions of both, as well as tapes for sealing joints.

-

What are the typical applications of ArmaFlex Ultima? It is used for insulating and protecting pipes, air ducts, vessels, and equipment in HVAC, refrigeration, and process equipment applications to prevent condensation and save energy.

-

Can ArmaFlex Ultima be used outdoors? If used outdoors or in areas exposed to UV radiation, ArmaFlex Ultima should be protected with a suitable covering like ArmaClad within 3 days of installation.

-

Does ArmaFlex Ultima resist fungal growth? Yes, ArmaFlex Ultima exhibits no fungal growth according to EN ISO 846 and VDI 6022, contributing to better indoor air quality.

-

Are there specific adhesives recommended for ArmaFlex Ultima? Yes, Armacell recommends ArmaFlex Ultima 700 and the solvent-free ArmaFlex Ultima SF990 adhesives to ensure a complete and reliable system.

-

Are there compatible pipe support solutions for ArmaFlex Ultima? Yes, ArmaFix Ultima pipe supports are specifically designed to be compatible with ArmaFlex Ultima tubes and sheets, preventing thermal bridges and maintaining the integrity of the insulation system.

-

Is ArmaFlex Ultima easy to install? ArmaFlex Ultima is flexible and easy to cut and install. Self-adhesive versions further simplify the installation process. Proper cutting techniques and seam sealing with ArmaFlex Ultima tape are essential.

-

Does ArmaFlex Ultima contribute to good indoor air quality? Yes, with very low VOC emissions and no observed fungal growth, ArmaFlex Ultima contributes to better indoor air quality.

-

Is ArmaFlex Ultima resistant to chemicals? While it offers good resistance to many common chemicals, it’s essential to consult the technical datasheet for specific chemical compatibility.

-

Where can I find more information or technical data about ArmaFlex Ultima? You can find detailed technical specifications, safety data sheets, and application guidelines on the Armacell website and potentially on Gitco-sa.com’s product page.

Brand

Armacell

| Property | Value / Assessment | Standard / Test method | ||||||

|---|---|---|---|---|---|---|---|---|

| Temperature range | ||||||||

| Service temperature1 |

|

EN 14706, EN 14707, EN 14304 | ||||||

| Thermal conductivity | ||||||||

| Declared thermal conductivity |

|

EN ISO 13787, EN 12667, EN ISO 8497 | ||||||

| Fire Performance and Approvals | ||||||||

| Reaction to fire | Tubes, Tubes self-adhesive, open tubes (up to 300 min insulated Øa): B(L)-s1,d0 Sheets, sheets self-adhesive: B-s2,d0 Tapes: B-s1,d0 |

EN 13501-1, EN ISO 11925-2, EN 13823 | ||||||

| Surface flammability2 | low-flammable – 2010 FTP-Code (MED 96/98/EC, Module D) | IMO 2010 FTP Code, Part 5 | ||||||

| FM approved3 | 4924-Pipe and Duct Insulation | UBC26-3 | ||||||

| Passive fire protection | ||||||||

| Fire resistance of elements of construction | EI 30 – EI 120 | EN 13501-2, EN 1366-3 | ||||||

| Fire performance | ||||||||

| Practical fire behaviour | Self-extinguishing, does not drip, does not spread flames; very low smoke density | |||||||

| Physical attributes | ||||||||

| Dimensions and tolerances | in accordance with EN 14304, table 1 | EN 822, EN 823, EN 13467 | ||||||

| Weather and UV resistance | ||||||||

| UV resistance | Protection against UV radiation is necessary (see Technical Bulletin no. 142). | |||||||

| Health and environment | ||||||||

| Volatile organic compounds (VOC) content | Fulfills all VOC requirements (French, Italian, Belgian, German AgBB, Blauer Engel and Eurofins Indoor Air Comfort GOLD). | ISO 16000 Parts 3, 6 & 9 | ||||||

| Antimicrobial behaviour | No fungal growth observed | EN ISO 846, VDI 6022 | ||||||

| Environmental aspects | Meets the requirements for sustainable construction in combination with ArmaFlex Ultima ECO550 adhesive such as LEED. | |||||||

| Environmental Product Declaration (EPD) | Type III Environmental Product Declaration (EPD): Declaration number “EPD-ARM-20200218-IBB1-EN”, Institut Bauen und Umwelt e.V. (IBU) | ISO 14025, EN 15804+A2 | ||||||

| Green building assessment | Meets the sustainable construction requirements for LEED v4.1, BREEAM international, WELL v2 and DGNB. | |||||||

| Additional features | SCCP, MCCP-free | |||||||

| Other technical features | ||||||||

| Adhesion and sealing | ArmaFlex Ultima ECO 550 and ArmaFlex Ultima 700 are the certified adhesives for this product. | |||||||

| Shelf life | Self-adhesive tubes, self-adhesive sheets, self-adhesive tape: 1 year | |||||||

| Storage | Can be stored in dry, clean rooms at normal relative humidity (50% to 70%) and ambient temperature (0 °C – 35 °C). | |||||||

|

1 For use in temperatures beyond the maximum and minimum service temperature range indicated in the technical data table, please contact our Customer Service Centre. 2 According to IMO 2010 FTP Code annex 2, clause 2.2 a fire technical test for smoke density and toxicity is not necessary. 3 Tube range: Maximum ID 89 mm and maximum wall thickness 25mm |

||||||||

Reviews

There are no reviews yet.