ArmaGel XGC: Cryogenic & Dual-Temp Aerogel Insulation

ArmaGel XGC: Flexible aerogel insulation blanket with an integrated zero-perm vapor barrier, ideal for combined cryogenic and dual-temperature applications. Compliant with ASTM C1728. Available at Gitco-sa.com (authorized Armacell distributor in Saudi Arabia & Bahrain).

Description

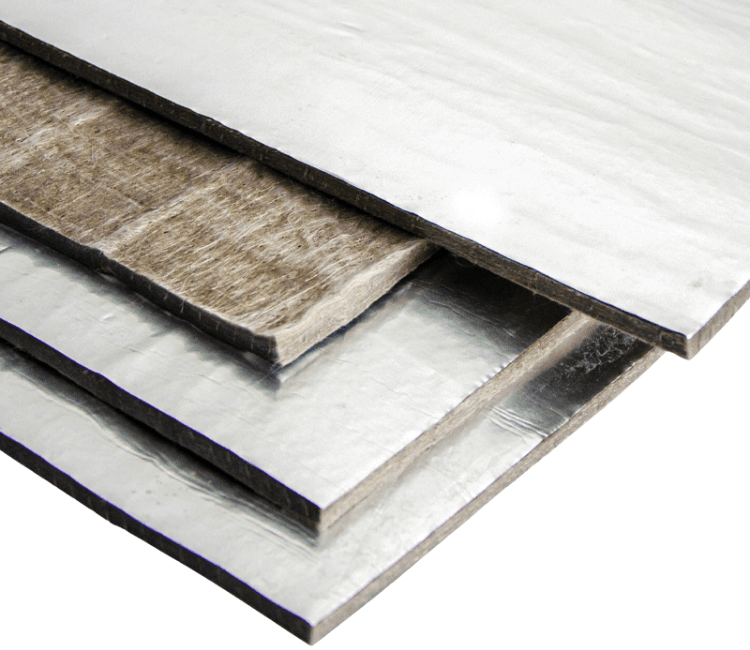

ArmaGel XGC is a cutting-edge flexible aerogel insulation blanket specifically engineered for the unique demands of both cryogenic and dual-temperature insulation applications. This advanced material is compliant with ASTM C1728 Type I, Grade 1B & Type IV, Grade 1A, ensuring high performance and reliability across a broad temperature range, from -180°C (-292°F) up to 250°C (482°F). A key feature of ArmaGel XGC is its integrated zero-perm vapor barrier, providing superior protection against moisture ingress in critical applications. Gitco-sa.com is a proud authorized distributor of Armacell products, including ArmaGel XGC, in Saudi Arabia and Bahrain.

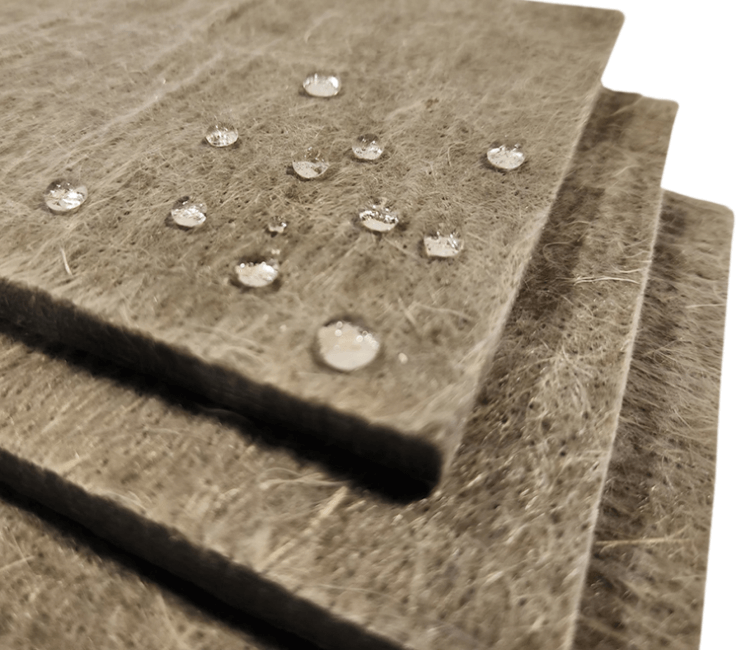

The flexible nature of ArmaGel XGC makes it easy to handle and install, even at cryogenic temperatures. Its exceptional thermal conductivity minimizes heat gain or loss, leading to significant energy savings. The integrated vapor barrier eliminates the need for additional layers, simplifying installation and ensuring long-term performance by preventing corrosion under insulation (CUI). ArmaGel XGC is hydrophobic, exhibits low water vapor sorption, and is non-corrosive to steel.

Key Features of ArmaGel XGC:

- Cryogenic and Dual-Temperature Application: Suitable for a wide temperature range (-180°C to +250°C).

- Integrated Zero-Perm Vapor Barrier: Provides superior moisture protection.

- ASTM C1728 Compliant: Meets stringent industry standards.

- Flexible at Cryogenic Temperatures: Easy to handle and install even in extreme cold.

- Ultra-Low Thermal Conductivity: Minimizes heat transfer for maximum energy efficiency.

- Hydrophobic: Repels water and resists moisture absorption.

- Non-Corrosive to Steel: Safe for use with various piping and equipment materials.

- High Compressive Strength: ≥ 34.5 kPa at 10% compression.

- Fungal Growth Resistant: Inhibits the growth of mold and mildew.

Product Variations of ArmaGel XGC:

ArmaGel XGC is available in the following standard thicknesses:

- 5 mm

- 10 mm

The material is supplied in flexible blanket form with standard roll widths. Please contact Gitco-sa.com for specific roll dimensions and availability of ArmaGel XGC in Saudi Arabia and Bahrain to meet your project’s specific thermal and mechanical requirements.

Applications of ArmaGel XGC:

- Cryogenic Insulation (LNG, etc.)

- Dual-Temperature Systems

- Energy Sector (pipelines, storage tanks)

- Industrial Facilities

- Acoustic Insulation (as a component in layered systems)

ArmaGel XGC – Frequently Asked Questions :

- What is ArmaGel XGC?

ArmaGel XGC is a flexible aerogel insulation blanket specifically designed for cryogenic and dual-temperature applications. - What makes ArmaGel XGC different from traditional insulation?

It utilizes advanced aerogel technology, providing superior thermal performance at a fraction of the thickness compared to conventional insulation materials. - What is the primary application of ArmaGel XGC?

Its main applications include insulating pipes, vessels, equipment, and fittings in cryogenic and dual-temperature systems within the oil & gas, industrial, and process sectors. - What is the service temperature range of ArmaGel XGC?

ArmaGel XGC is suitable for applications ranging from cryogenic temperatures down to -180°C (-292°F) up to +250°C (+482°F). - Is ArmaGel XGC hydrophobic?

Yes, it repels liquid water, which helps to mitigate the risk of corrosion under insulation (CUI) by keeping equipment drier for longer. - Is ArmaGel XGC an ultra-thin insulation material?

Yes, it offers equal thermal performance at a significantly reduced thickness compared to traditional insulation. - Is ArmaGel XGC lightweight?

Yes, its low density makes it lightweight, improving handling and transportation efficiency. - Does ArmaGel XGC offer acoustic benefits?

Yes, its sound absorption properties and low dynamic stiffness provide excellent acoustic capabilities, meeting and exceeding insertion loss classifications according to ISO 15665 in system configurations. - What is the fire performance rating of ArmaGel XGC?

ArmaGel XGC has a surface burning characteristic rating of ≤ 25 for flame spread index and ≤ 50 for smoke development according to ASTM E84. - Does ArmaGel XGC have an integrated vapor barrier?

Yes, it features an integrated zero-perm vapor barrier, providing excellent resistance to water vapor permeance (0.00 perm according to ASTM E96). - Is ArmaGel XGC flexible and easy to install?

Yes, it is a flexible blanket that can be easily cut and conformed to various shapes, which can help reduce installation costs and labor time. - Does ArmaGel XGC help in preventing corrosion under insulation (CUI)?

Yes, its hydrophobic properties and integrated vapor barrier enhance protection against CUI. - What is the shelf life of ArmaGel XGC?

The maximum shelf life is typically up to 3 years when stored indoors in clean and dry conditions away from direct sunlight. - What is the nominal density of ArmaGel XGC?

The nominal density is around 170 kg/m³ (10.6 lb/ft³) according to ASTM C303. - Is ArmaGel XGC suitable for multi-layer applications?

Yes, it is suitable for use in multi-layer applications, including with ArmaSound Industrial Systems for enhanced acoustic insulation. - Does ArmaGel XGC pass corrosiveness tests for steel?

Yes, it passes the corrosiveness to steel test according to ASTM C1617, Procedure A. - Does ArmaGel XGC resist fungal growth?

Yes, it shows no fungal growth when tested according to ASTM C1338. - What are the available thicknesses for ArmaGel XGC sheets?

It is available in sheets with thicknesses of 5 mm (0.2 in.) and 10 mm (0.4 in.), with a width of 1.5 m (59 in.). - Are there any specific installation recommendations for ArmaGel XGC in industrial settings?

Yes, it is recommended to consult the relevant Armacell application manuals for industrial applications to ensure proper installation. - Why choose ArmaGel XGC for cryogenic and dual-temperature insulation?

ArmaGel XGC offers a reliable solution with superior thermal performance, ultra-thin profile, lightweight nature, hydrophobicity, CUI defense, and acoustic benefits, specifically designed for the demanding conditions of cryogenic and dual-temperature applications.

For ultimate thermal performance and moisture protection in cryogenic and dual-temperature applications, choose ArmaGel XGC from Gitco-sa.com, your authorized Armacell distributor in Saudi Arabia and Bahrain.

Brand

Armacell

| Property | Value / Assessment | Standard / Test method | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature range | |||||||||||||||||||||||||||||

| Service temperature1 |

|

ASTM C411 | |||||||||||||||||||||||||||

| Thermal conductivity | |||||||||||||||||||||||||||||

| Declared thermal conductivity2 |

|

ASTM C177 | |||||||||||||||||||||||||||

| Temperature resistance | |||||||||||||||||||||||||||||

| Linear shrinkage under soaking heat | < 2% in width and length | ASTM C356 | |||||||||||||||||||||||||||

| Fire Performance and Approvals | |||||||||||||||||||||||||||||

| Surface burning characteristics | ≤ 25 flame spread index ≤ 50 smoke development |

ASTM E84 | |||||||||||||||||||||||||||

| Resistance to water vapour | |||||||||||||||||||||||||||||

| Water vapour sorption | ≤ 5% by weight | ASTM C1104 | |||||||||||||||||||||||||||

| Water vapour permeance of integrated vapour barrier | 0.00 perm | ASTM E96 | |||||||||||||||||||||||||||

| Resistance to water | |||||||||||||||||||||||||||||

| Hydrophobic | Yes | ||||||||||||||||||||||||||||

| Water absorption | Pass | ASTM C1763 | |||||||||||||||||||||||||||

| Corrosion mitigation | |||||||||||||||||||||||||||||

| Corrosiveness to steel | Pass | ASTM C1617, Procedure A | |||||||||||||||||||||||||||

| Stress corrosion cracking | Pass, no cracks | ASTM C692, ASTM C795 | |||||||||||||||||||||||||||

| Physical attributes | |||||||||||||||||||||||||||||

| Nominal density | 170 kg/m³ (10.6 lb/ft³) | ASTM C303 | |||||||||||||||||||||||||||

| Mechanical properties | |||||||||||||||||||||||||||||

| Compressive strength3 | ≥ 5 psi / 34.5 kPa at 10% compression | ASTM C165 | |||||||||||||||||||||||||||

| Flexibility of insulation blankets | Flexible | ASTM C1101 | |||||||||||||||||||||||||||

| Weather and UV resistance | |||||||||||||||||||||||||||||

| Weather resistance | In all industrial applications the outer layer of the material must be protected with an adequate covering like metal jacketing or preformed UV-cured GRP (Glass-Reinforced Plastic) cladding. Please contact Technical Services for guidance on the temperature limitations and specific construction considerations which need to be made for each jacketing system. | ||||||||||||||||||||||||||||

| Health and environment | |||||||||||||||||||||||||||||

| Fungal growth | No growth | ASTM C1338 | |||||||||||||||||||||||||||

| Health aspects | Neutral | ||||||||||||||||||||||||||||

| Other technical features | |||||||||||||||||||||||||||||

| Shelf life4 | Max. 3 years | ||||||||||||||||||||||||||||

| Storage | Material shall be stored indoors, in clean and dry conditions, away from direct sunlight. | ||||||||||||||||||||||||||||

|

1For operating temperatures below -180°C, special attention must be given to the system design and craftsmanship during installation to ensure that the material does not come in contact with liquid oxygen. For further information and support, please contact Technical Services. 2Measured under a load of 1.5 kPa (0.22 psi). 3Test performed with a preload of 13.8 kPa (2 psi). 4Shelf life (maximum storage time) is limited to ensure that only currently manufactured products are installed on projects. This limitation is restricted solely to storage of the product and does not affect the lifetime of product after it has been installed. |

|||||||||||||||||||||||||||||

Reviews

There are no reviews yet.