Expanded Perlite Insulation

Expanded Perlite Insulation is a lightweight, inorganic, Asbestos-free granular material derived from volcanic glass. It is primarily used as loose fill insulation in cryogenic tank annular spaces and high-temperature voids. This high quality product is one of the best isolation products for achieving extremely low thermal conductivity. Gitco-sa.com supplies the complete range across Saudi Arabia.

Description

Expanded Perlite is produced by rapidly heating crushed Perlite ore, a naturally occurring siliceous volcanic glass. This process causes the material to expand (or ‘pop’) up to 20 times its original volume, transforming it into a white, highly porous, granular material with a microscopic cellular structure. This structure traps air, providing its outstanding insulating properties. The material is inherently non-combustible and Asbestos-free, meeting stringent fire and safety regulations.

Specialized Use: Loose Fill for Cryogenic Tanks

The core application of this product is as a granular insulation material filled in tank annular space (the gap between the inner and outer shells of double-walled vessels). This is critical for cryogenic systems storing liquefied gases like LNG, Oxygen, Nitrogen, and Helium at temperatures as low as -268 °C.

Key performance characteristics include:

-

Extremely Low Thermal Conductivity: Under moderate vacuum conditions, expanded perlite can achieve exceptionally low thermal conductivity (λ≈ 0.025 – 0.042 W/(m.K) in non-evacuated service), which is vital for minimizing boil-off losses in storage tanks.

-

Ease of Installation: Perlite loose fill insulation is pneumatically conveyed and poured or blown into the annular space, easily filling complex and large void areas with minimal dust and labor, even in large field-erected tanks in Dammam or Al Jubail.

-

Durability and Stability: The inorganic material does not rot, shrink, swell, or slump over time, ensuring a permanent and reliable insulation layer throughout the life of the vessel.

-

Material Source: We offer both domestic and imported ore based on customer’s request and project specifications, guaranteeing the high quality required for industrial service.

The Complete Range of Expanded Perlite Products

While specializing in loose fill, Gitco-sa.com ensures the complete range of high quality Perlite materials is available:

-

Cryogenic Loose Fill: Specialized granular insulation for double-walled LNG tanks and Air Separation Units (Cold Boxes).

-

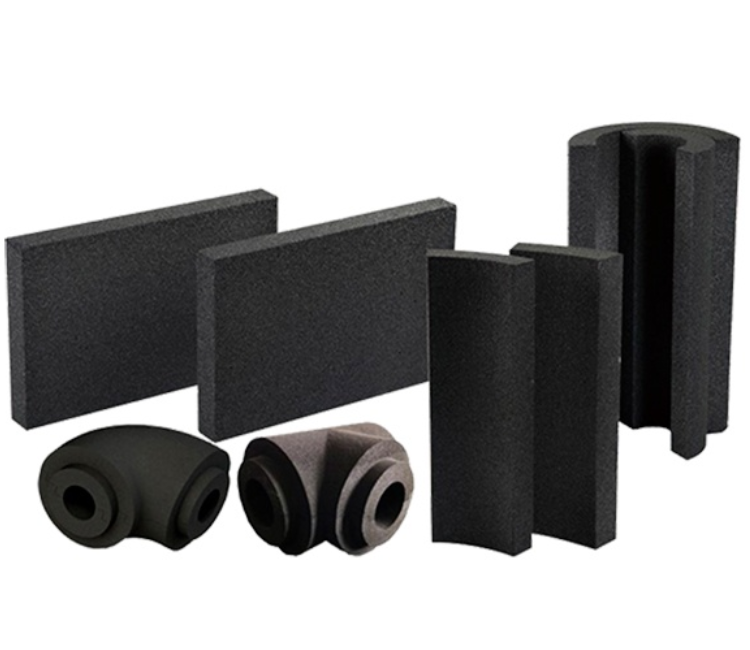

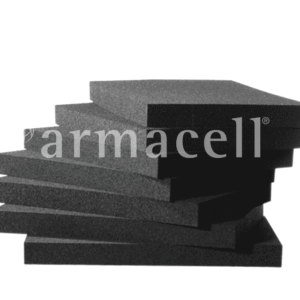

Perlite Insulating Boards/Slabs: Rigid, bonded boards used for high-temperature insulation in industrial furnaces and vessels (up to+1000 °C) or for structural elements in roof insulation.

-

Lightweight Aggregate: Used as a mix-in for concrete and plaster to reduce weight and improve fire-rating and insulation in building insulation.

We guarantee that our Expanded Perlite Insulation materials are the best isolation products for controlled temperature environments. Gitco-sa.com ensures the complete range of these high quality materials is available for delivery and complex industrial project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about Expanded Perlite Insulation:

- What is Expanded Perlite?

It is a lightweight, white, porous, siliceous volcanic glass mineral that has been rapidly heated to high temperatures. - What causes the “expansion” of perlite?

When the crude perlite ore is heated rapidly to 850 °C to 1,100 °C, the chemically bound water inside the ore vaporizes, causing the glass structure to soften and expand up to 20 times its original volume, forming air-filled cells. - What is the chemical makeup of Perlite?

It is primarily composed of silica (SiO2) and alumina (Al2 O3) along with other metallic oxides. - In what forms is Expanded Perlite used for insulation?

It is used as loose-fill granules, as an aggregate in lightweight insulating concrete, and as the primary component in pre-formed blocks, boards, and pipe sections (molded with an inorganic binder). - Is Expanded Perlite chemically active?

No, it is chemically inert and possesses a neutral pH (around 6.5-8.0), ensuring it will not react with other construction materials or stored cryogenic liquids. - What is the maximum service temperature for Expanded Perlite insulation?

Expanded Perlite is highly heat-resistant, with a softening point around 871 °C and a fusion point up to 11,343 °C, making it suitable for continuous use up to 650 °C (1,200°F). - Is Expanded Perlite considered fire-resistant?

Yes, it is non-combustible (Class A1 or ASTM E136) and will not burn or carry flame, giving it a zero flame spread and zero smoke developed rating (ASTM E84). - What is its typical thermal conductivity (λ)?

It has low thermal conductivity, generally ranging from 0.045 to 0.065 W/(m·K) at ambient temperatures, providing excellent thermal resistance. - How is it used in high-temperature applications?

It is used in refractory bricks, furnace insulation, and pipe insulation for hot industrial processes (like steam lines) due to its high heat stability. - How does Perlite compare to other insulations in terms of fire safety?

As an inorganic mineral product, it offers a distinct fire safety advantage over organic foam insulations (PUR/PIR/EPS) which are combustible or emit smoke/toxic gases upon burning. - Why is Perlite an ideal choice for cryogenic applications?

In its loose-fill form, Perlite is a popular, cost-effective insulator for the annular spaces (the gap between inner and outer walls) of double-walled cryogenic storage tanks (e.g., LNG, LOX). - What temperature range does cryogenic Perlite insulation cover?

Cryogenic grade Perlite is effective for temperatures as low as -273 °C (452°F), making it suitable for virtually all cryogenic liquids, including liquid nitrogen and helium. - What is “Evacuated Perlite Super Insulation”?

This refers to Perlite insulation used in the annular space of a cryogenic vessel where a vacuum is also applied, drastically reducing the thermal conductivity (λ), and achieving “super” insulating performance. - How does Perlite prevent Corrosion Under Insulation (CUI)?

Perlite pipe and block insulation for industrial use often contains integral inorganic silicate chemistry to inhibit corrosion on steel piping. - Is Perlite insulation resistant to pests?

Yes, as an inorganic mineral, it is rot-proof, vermin-proof, and pest-proof, ensuring long-term integrity in walls and foundations. - How is Expanded Perlite used in lightweight concrete?

It is used as an aggregate in lightweight insulating concrete for roof decks and floor slabs, reducing structural load while adding thermal insulation. - How is it used in masonry construction?

It is poured as loose-fill insulation into the cavities of concrete block walls to significantly improve the thermal resistance (R-value) of the wall assembly. - Does Perlite have acoustic properties?

Yes, its porous, air-filled cellular structure gives it good sound absorption and acoustic insulation capabilities when used in plasters, ceiling tiles, and wall cavities. - Does Perlite absorb water?

The raw expanded perlite is porous and can absorb water. However, for construction and industrial use, it is often treated with a hydrophobic (water-repelling) agent or binder to minimize moisture absorption. - What industry standards govern Expanded Perlite Insulation?

Molded block and pipe insulation must meet standards such as ASTM C610 (Standard Specification for Expanded Perlite Block and Pipe Thermal Insulation).

Brand

Zhenshen Insulation

Zhenshen Insulation is a trusted global manufacturer recognized for delivering high-performance insulation solutions, particularly their advanced Cellular Glass (Foam Glass) products. As a supplier of Aramco and SABIC approved products, Zhenshen meets the rigorous quality, safety, and durability standards demanded by the largest industrial and energy corporations in the Kingdom of Saudi Arabia. All Zhenshen products comply with stringent ASTM standards, guaranteeing reliability for critical applications.

Zhenshen Cellular Glass Insulation (Foam Glass/Foamglas) is the cornerstone of their industrial offering, renowned for its:

-

Absolute Vapor Impermeability: The closed-cell structure makes it a definitive vapor barrier, preventing moisture migration and eliminating the risk of Corrosion Under Insulation (CUI), vital for long-term reliability in cold insulation and hot insulation systems.

-

Non-Combustibility: Being inorganic, it is inherently fireproof, providing a crucial safety layer in LNG tank, pipeline, and chemical processing environments.

-

High Compressive Strength: Its rigidity makes it ideal for high-load applications, including cryogenic tank bases and pipe supports, ensuring system integrity.

The Complete Range of Zhenshen Insulation Products

Gitco-sa.com supplies the complete range of high quality Zhenshen Insulation materials, ensuring compliance and availability for major projects:

-

Cellular Glass Pipe Sections: Pre-formed insulation for pipeline insulation in LNG, cold, hot, and medium-temperature systems. Available for various pipe sizes and thicknesses, compliant with ASTM standards.

-

Foam Glass Slabs & Boards: Used for LNG tank bases (cryogenic systems), equipment, vessels, roof insulation, and wall insulation in industrial and commercial building insulation projects.

-

Tapered & Curved Sections: Custom Foam Glass segments for precise insulation of large vessels, tanks, and structural elements, ensuring thermal continuity.

-

Specialized Industrial Grades: Products engineered specifically for the extreme conditions found in petrochemical and hydrocarbon processing systems, carrying the distinction of being Aramco and SABIC approved products.

We guarantee that our Zhenshen Insulation products are the best isolation products for achieving maximum durability and safety. Gitco-sa.com ensures the complete range of these high quality, Aramco and SABIC approved materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications

-

Industrial/Energy: LNG tank and cryogenic tank insulation, pipeline insulation (hot and cold), and process equipment in Hydrocarbon Processing and Chemical Processing Systems.

-

Building & Construction: Roof insulation, wall insulation, and structural insulation for commercial and industrial buildings requiring high fire ratings and moisture control.

-

Waterproofing: Used in conjunction with construction and roofing materials due to its zero-permeability.

Reviews

There are no reviews yet.