Getzner Sylomer FR Pads: Fire-Retardant Vibration Isolation

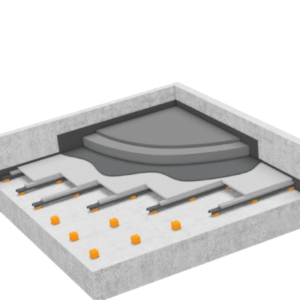

Getzner Sylomer® FR (Fire-retardant) is a high quality polyurethane elastomer offering exceptional vibration and noise reduction while achieving the highest fire classification (HL3) according to EN 45545-2. Gitco-sa.com has the complete range of these best isolation products across Saudi Arabia.

Description

Getzner Sylomer® Fire-retardant (FR) pads are specialized isolation materials developed to meet the stringent safety and performance requirements of environments where fire protection is critical, such as rail vehicle construction and public infrastructure. This material retains all the renowned vibration and noise reduction characteristics of standard Sylomer®, while incorporating fire-retardant particles to ensure maximum safety.

A key competitive advantage is its certification to the highest fire classification, HL3 (Hazard Level 3), according to the European standard EN 45545-2. This compliance makes Sylomer® FR the material of choice for applications like floating floors in rolling stock, where polyurethane components must meet strict safety mandates. The material boasts a low weight (optimised for lightweight construction) and ensures consistent vibration and noise reduction over the entire service life.

The Complete Range of Sylomer® FR

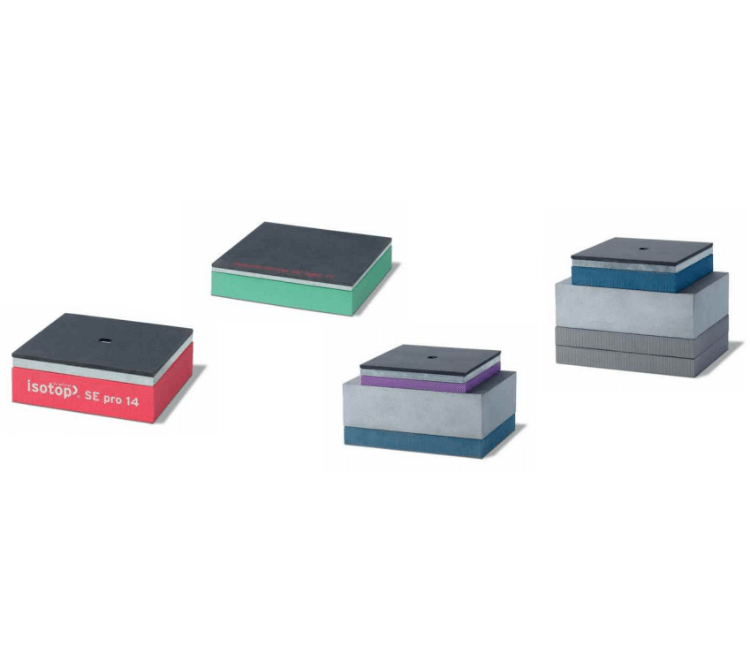

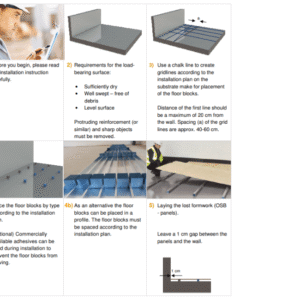

Gitco-sa.com provides the complete range of Sylomer® FR, tailored to various load and deflection requirements. The range is defined by four distinct densities or “graduations” for optimum layout:

-

Density/Graduation Range: Sylomer® FR is available in four specific material densities (e.g., Sylomer FR 328, 355, 3110, 3220).

-

Static Load Capacity: The static application range is wide, spanning from 0.028 mm up to 0.220 mm (corresponding to different grades).

-

Load Peak Tolerance: The material can handle load peaks up to 4.0 N/mm, providing excellent protection against dynamic shock and impact.

-

Format: Available in standard sheet forms, which can be cut into any shape or thickness required for applications like bearing pads, strips, or custom die-cut parts, ensuring a complete range of fitting options.

Key Applications

-

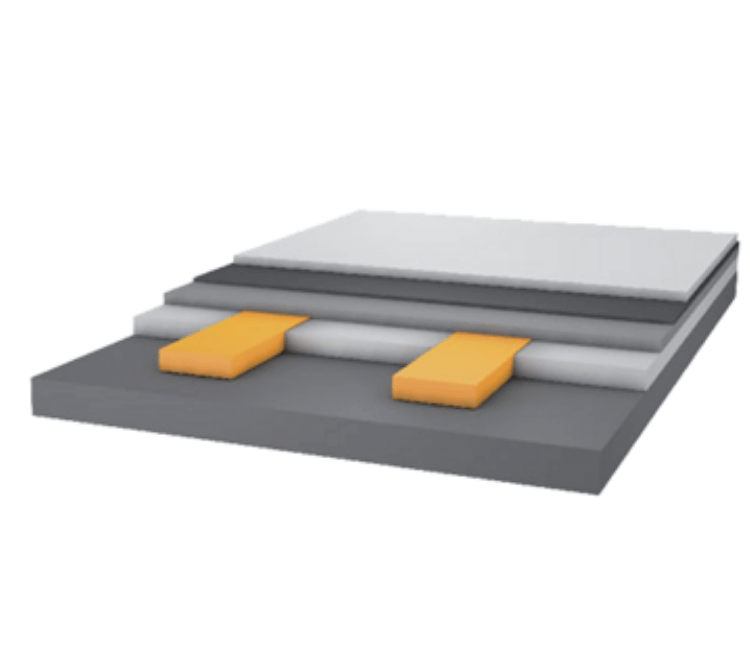

Rail Vehicle Construction (Rolling Stock): Used in floating floors and component isolation within passenger carriages and trains, where EN 45545-2 HL3 compliance is mandatory.

-

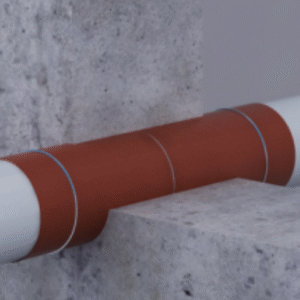

Public Infrastructure and Tunnels: Isolation bearings for equipment or structural elements in fire-sensitive areas (e.g., ventilation systems, communication rooms).

-

Marine and Offshore: Applications within ships, oil rigs, and platforms where fire-retardant materials are critical for crew and asset safety alongside vibration control.

We guarantee that our Sylomer® FR pads are the best isolation products for achieving critical safety compliance alongside superior acoustic and vibration control. Gitco-sa.com ensures the complete range of these high quality materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about FR Pads:

- What is Sylomer® FR?

It is a high-performance, mixed-cell polyurethane elastomer specifically formulated with fire-retardant (FR) additives to achieve superior fire safety classifications while maintaining its elastic properties. - What is the core purpose of the fire-retardant effect?

The main purpose is to prevent the material from igniting easily and, more crucially, to limit the development of smoke and toxic gases in the event of a fire, protecting people and infrastructure. - What is the highest fire safety standard Sylomer® FR often meets?

For applications like rail vehicle construction, Sylomer® FR meets the demanding Hazard Level 3 (HL3) classification according to the EN 45545-2 standard (requirements R10 and R22). - What international standards confirm its suitability for ships and offshore?

The specialized Sylomer® Marine FR series is certified to IMO Res.4 and MSC. 307 (88) FTP Code 2 and 5 (referred to in the SOLAS Convention) and carries the Wheelmark approval. - Does the FR material produce toxic smoke?

A key selling point is that the material is designed and certified to ensure the protection of people by not producing toxic smoke during combustion, as tested under standards like ISO 5659-2. - Where is Sylomer® FR most commonly used in transportation?

It is primarily used for the elastic bearing of floating floors in rail vehicle construction (passenger carriages) and in decoupling cabins and engine rooms on ships. - Why is the FR material necessary in rail carriage construction?

Fire protection standards like EN 45545-2 mandate high fire safety classifications for materials used in areas like floating floors within rolling stock to enhance passenger safety. - How is Sylomer® FR used on ships and offshore platforms?

It is used for effective sound and vibration isolation in crew and passenger cabins and under machinery, often certified as “Primary Decks Covering.” - Can Sylomer® FR be used for anti-vibration mounts in industrial machinery?

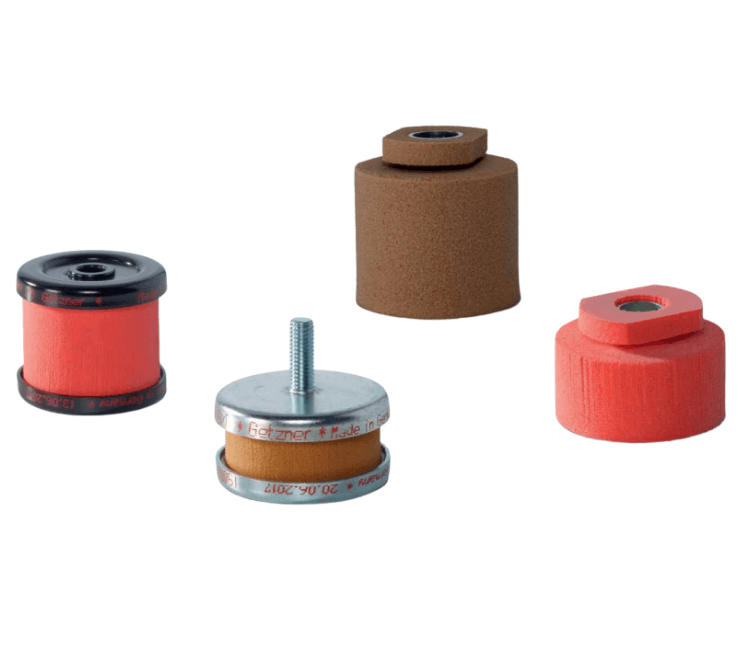

Yes, it is used for anti-vibration mounts in machine and plant engineering, especially in industrial areas where fire risk is elevated. - Is the material used in general construction and building foundations?

Yes, while its FR properties make it crucial for transport, the material can also be specified for structural bearings in buildings where strict fire separation is required. - Does the fire-retardant treatment compromise the material’s damping properties?

No, Sylomer® FR is engineered to retain the exceptional damping characteristics and long-term elastic behaviour of the standard Sylomer® product range. - What is the typical mechanical loss factor (n)?

The mechanical loss factor for Sylomer® FR is typically high (e.g., 0.25 to 0.28), indicating excellent damping (vibration absorption). - What is the static application range (static loads) of Sylomer® FR?

The static application range varies by type (e.g., FR 355, FR 3110), covering static loads from as low as 12$0.028N/mm² up to 0.220 N/mm² per type. - How does the material reduce secondary airborne noise?

By effectively damping vibrations at the source, the material significantly reduces the generation and transmission of secondary airborne noise radiated by vibrating structural surfaces. - What is the expected lifespan under load?

Like standard Sylomer®, the FR variant exhibits proven long-term behaviour, designed to maintain its properties over decades of use under permanent load due to its low creep tendency. - Is the material available in different densities/stiffnesses?

Yes, the Sylomer® FR range is available in multiple graduations (different types with varying colours and densities) to allow for optimum selection based on specific load requirements. - What are the typical standard delivery dimensions?

The material is typically available in standard thicknesses (e.g., 12.5 mm, 25 mm, 50 mm) and supplied in mats or long strips. - Can Sylomer® FR be supplied with adhesive backing?

Yes, other dimensions, stamped parts, and a self-adhesive equipment option are available upon request to facilitate easier installation. - What is the material’s temperature range?

The permissible operating temperature range for Sylomer® FR is typically from -30 °C up to +70 °C, with tolerance for short-term higher temperatures.

Brand

Getzner

Reviews

There are no reviews yet.