Rockwool HD Board: High-Density Industrial Insulation Blanket

Rockwool HD Board is a premium, high-density insulation for critical industrial applications, offering exceptional thermal, acoustic, and fire performance. Gitco-sa.com provides a complete range of this product, with the lowest prices for Cavity Panels and budget-friendly Loose Wool in Saudi Arabia, UAE, and Bahrain.

Description

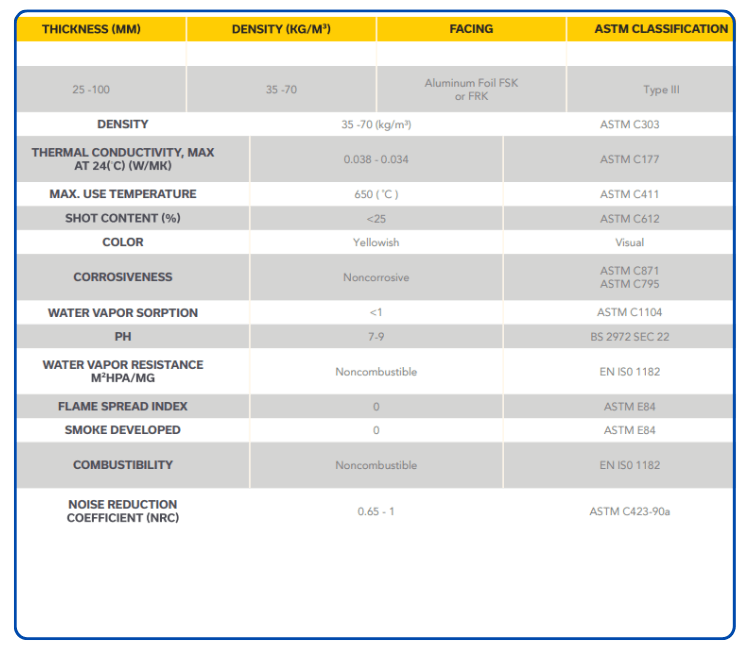

Rockwool HD Board is a high-density, rigid insulation slab engineered for demanding industrial and commercial applications. The product is made from molten basalt rocks spun into fine fibers and bonded with a thermosetting binder, creating a durable and stable material. This composition provides exceptional thermal resistance, with a thermal conductivity ranging from 0.035 to 0.034 W/m.K at 24°C. It also offers superior sound absorption with a Noise Reduction Coefficient (NRC) between 0.85 and 1.0, making it an excellent choice for noise control in loud environments.

The board is non-combustible, holding the highest Euro Class A1 fire classification, with a Flame Spread Index of 0 and Smoke Developed rating of 0, ensuring maximum fire safety. It is also non-corrosive, has a high compressive strength of 20-60 kPa, and does not encourage fungi growth. Gitco-sa.com offers a complete range of these high-density boards, with variations in thickness from 25 mm to 150 mm and densities from 80 kg/m³ to 160 kg/m³. The product is available unfaced or with an Aluminum Foil facing, providing options for different project needs.

Key Applications of Rockwool HD Board:

- Industrial Equipment: Ideal for insulating high-temperature equipment, boilers, ovens, and furnaces due to its high maximum use temperature of 750°C.

- Building Structures: Used as a durable, fire-resistant core for walls, ceilings, and partitions in commercial and industrial buildings.

- Acoustic Barriers: Provides a robust solution for noise control in loud mechanical rooms, factories, and power plants.

- Underfloor Heating Systems: Serves as a thermal break to increase the efficiency of underfloor heating systems.

Our Cavity Panels prices are the Lowest for Cavity Panels products, and we provide budget-friendly Loose Wool in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia, UAE, and Bahrain, with a complete range to meet all your project needs.

Know More about Rockwool HD Board:

1. What is a fire board?

A fire board is a specialized, fire-resistant construction panel designed to serve as a passive fire protection barrier. It is used to compartmentalize buildings and delay the spread of fire and smoke.

2. How does a fire board work?

Fire boards act as a physical barrier. They are made of non-combustible materials that can withstand extremely high temperatures. Some types, like gypsum boards, contain water crystals that release steam when heated, which helps to cool the structure and slow the spread of fire.

3. What materials are fire boards made of?

Common materials include calcium silicate, gypsum (Type X or Type C), magnesium oxide (MgO), and mineral wool (rock wool or glass wool). The specific composition determines the board’s properties and applications.

4. What is the difference between fire-rated and flame-retardant?

Fire-rated materials are tested to maintain their structural integrity and prevent fire spread for a specific duration (e.g., 30, 60, or 120 minutes). Flame-retardant materials are treated to resist ignition and slow the rate of burn, but they may not act as a complete barrier.

5. What are the main applications of fire boards?

Fire boards are used to protect:

- Structural steel: Wrapping steel beams and columns to prevent them from reaching a critical temperature and collapsing.

- Walls and ceilings: Creating fire-rated partitions in buildings.

- Ducts: Insulating HVAC ducts to prevent the spread of fire through ventilation systems.

- Chimneys and flues: Lining these structures to contain high temperatures.

6. What fire rating standards do they adhere to?

In Europe and the Middle East, a key standard is Euroclass EN 13501-1. Many fire boards achieve the highest rating, A1, which means they are completely non-combustible.

7. What is the melting point of a mineral wool fire board?

Mineral wool (rock wool or glass wool) fire boards have a very high melting point, typically exceeding 1000°C, making them highly effective in extreme heat conditions.

8. How do fire boards for steel structures work?

Steel loses its strength and can buckle at around 550°C. Fire boards for steel protection are applied as a cladding or box enclosure around the steel to keep its temperature below this critical point for a specified period, allowing for safe evacuation.

9. Are fire boards used for ducts?

Yes, they are crucial for insulating ventilation and smoke extraction ducts. They ensure that a fire does not spread from one area to another via the ductwork.

10. Can they be used on floors?

Yes, certain types of fire boards are used in floor systems to provide fire resistance ratings and improve sound insulation between floors.

11. Are they considered a sustainable building material?

Many fire boards, particularly those made from natural or recycled materials like mineral wool or gypsum, are considered a more sustainable choice. They also contribute to a building’s energy efficiency.

12. Are there different types of gypsum fire boards?

Yes, Type X and Type C gypsum boards are enhanced with glass fibers and other additives to improve their fire resistance. Type C boards offer even greater protection and are used where higher fire ratings are required.

13. What are the benefits of calcium silicate fire boards?

Calcium silicate boards are lightweight, rigid, and offer high fire resistance and durability. They are also moisture-resistant, making them suitable for use in high-humidity areas.

14. Do fire boards have acoustic properties?

Yes, the dense, fibrous structure of many fire boards, especially mineral wool, provides excellent sound absorption and acoustic insulation, helping to reduce noise transfer between spaces.

15. What are the common thicknesses of fire boards?

Fire boards come in various thicknesses, typically ranging from 12.5 mm to 50 mm. The required thickness depends on the desired fire rating (e.g., 30, 60, 90, or 120 minutes).

16. Do they contain asbestos?

No, modern fire boards are asbestos-free and do not contain other harmful substances. Manufacturers adhere to strict health and safety standards.

17. How is a fire board installed?

Installation typically involves cutting the board to size and attaching it to the structure using screws, adhesives, or specialized fasteners. All joints and seams must be properly sealed with fire-rated sealant or tape to maintain the integrity of the barrier.

18. What is the main advantage of using fire boards?

The main advantage is passive fire protection. Fire boards are always on and don’t require power to function, providing crucial time for occupants to evacuate a building safely.

19. Where can I find suppliers of fire boards in the UAE and Saudi Arabia?

Companies like Gitco-sa.com and other specialized distributors for manufacturers like Saudi Rockwool are key suppliers of certified fire-rated boards in the GCC region.

20. Do fire boards help a building achieve certifications like LEED?

Yes, by contributing to a project’s overall fire safety and using low-VOC, responsibly sourced materials, fire boards can help a building earn points towards certifications like LEED (Leadership in Energy and Environmental Design).

Reviews

There are no reviews yet.