HT/ArmaFlex, High-Temp Insulation, UV Resistant Insulation

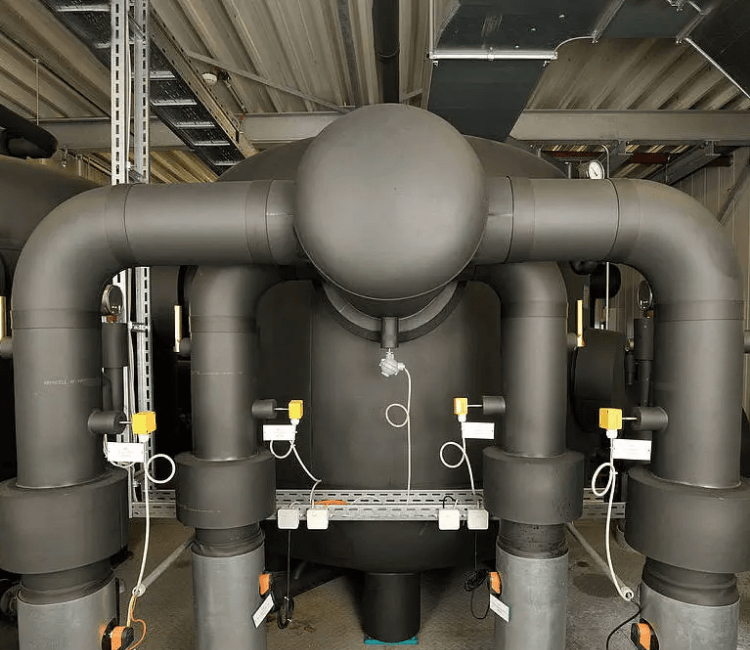

HT/ArmaFlex: Highly flexible, closed-cell elastomeric insulation specifically designed for high-temperature applications up to +150°C with very good UV resistance. Available at Gitco-sa.com (authorized Armacell distributor in Saudi Arabia & Bahrain).

Description

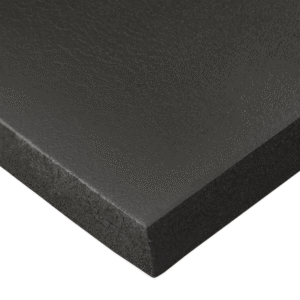

HT/ArmaFlex is a professional-grade, highly flexible, closed-cell elastomeric insulation material expertly engineered for demanding high-temperature applications, reaching up to +150°C. Its EPDM (ethylene propylene diene methylene) based composition ensures excellent thermal performance and inherent resistance to UV radiation, making it suitable for a wide range of industrial and commercial uses. Gitco-sa.com is a trusted authorized distributor of Armacell products, including HT/ArmaFlex, in Saudi Arabia and Bahrain.

This UL-approved insulation solution is designed for long-term reliability in elevated temperature environments. While some inner surface hardening may occur at very high temperatures, the material retains its crucial physical and fire protection properties when installed correctly with properly sealed joints. For optimal system integrity, it is recommended to use the fit-for-purpose ArmaFlex HT625 Adhesive.

Key Features of HT/ArmaFlex:

- High Temperature Application: Designed for continuous use up to +150°C.

- Very Good UV Resistance: Suitable for applications exposed to sunlight.

- Highly Flexible: Easy to install around complex shapes and fittings.

- Closed-Cell Structure: Provides effective thermal insulation and resistance to moisture ingress.

- UL 94 V-0 Approved: Meets stringent flammability requirements for certain thicknesses.

- Self-Extinguishing: Does not drip or spread flames in case of fire.

- Class 1 (BS 476 Part 7): Meets recognized fire propagation standards.

- Low VOC Content: Fulfills all VOC requirements (Eurofins Indoor Air Comfort GOLD certified).

- Meets Green Building Standards: Complies with LEED v4.1, BREEAM international, WELL v2, and DGNB requirements.

- SCCP and MCCP-Free: Environmentally conscious material composition.

Product Variations of HT/ArmaFlex:

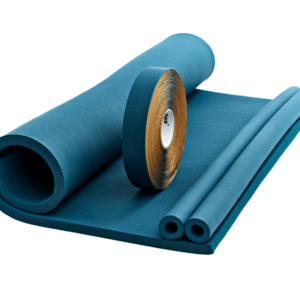

HT/ArmaFlex is available in various forms to suit diverse high-temperature application needs:

- Tubes: Available in various thicknesses and inner diameters to fit different pipe sizes.

- Sheets (Rolls): Available in various thicknesses and standard roll widths for insulating larger surfaces like tanks and ducts.

- Tapes: Insulation tapes for sealing joints and seams, often self-adhesive for easy application.

- Tube – standard. 2m Length, 10 mm: HT-10X010, HT-10X012, HT-10X015, HT-10X018, HT-10X022, HT-10X028, HT-10X035, HT-10X042

- Tube – standard. 2m Length, 13 mm: HT-13X010, HT-13X012, HT-13X015, HT-13X018, HT-13X022, HT-13X028, HT-13X035, HT-13X042, HT-13X048, HT-13X054, HT-13X060, HT-13X076, HT-13X089

- Tube – standard. 2m Length, 19 mm: HT-19X012, HT-19X015, HT-19X018, HT-19X022, HT-19X028, HT-19X035, HT-19X042, HT-19X048, HT-19X054, HT-19X060, HT-19X064, HT-19X076, HT-19X089

- Tube – standard. 2m Length, 25 mm: HT-25X015, HT-25X018, HT-25X022, HT-25X028, HT-25X035, HT-25X042, HT-25X048, HT-25X054, HT-25X060, HT-25X076, HT-25X089

- Roll – standard: HT-10-99/E, HT-13-99/E , HT-19-99/E, HT-25-99/E, HT-32-99/E

- Coil: HT-13X015/E, HT-13X018/E, HT-13X022/E, HT-19X015/E, HT-19X018/E, HT-19X022/E

- Tape – insulation: HT-TAPE

Please contact Gitco-sa.com for detailed information on specific part numbers, dimensions, and availability of HT/ArmaFlex variations in Saudi Arabia and Bahrain to meet your exact project requirements. Thermal conductivity values vary slightly between tubes and sheets/tapes, as indicated in the technical data.

Applications of HT/ArmaFlex :

- Energy Sector

- Thermal Insulation for high-temperature pipes and equipment

- Transportation

- Commercial Applications with elevated temperatures

- Industrial Processes

- OEM (Original Equipment Manufacturer) components

- Residential applications with specific high-temperature requirements

HT/ArmaFlex – Frequently Asked Questions:

Know More about HT/ArmaFlex, a highly flexible, closed-cell insulation material with resistance to UV radiation:

- What is HT/ArmaFlex?

HT/ArmaFlex is a flexible, closed-cell elastomeric foam insulation material specifically engineered for high-temperature applications and outdoor environments. - What makes HT/ArmaFlex unique?

Its unique formulation based on EPDM rubber provides exceptional resistance to UV radiation, weathering, and high temperatures up to +150°C. - What is the maximum service temperature of HT/ArmaFlex?

HT/ArmaFlex can withstand continuous service temperatures up to +150°C. - Is HT/ArmaFlex suitable for outdoor applications?

Yes, its excellent UV and weather resistance make it ideal for outdoor installations without requiring additional protective jacketing in many cases. - Does HT/ArmaFlex have a built-in vapor barrier?

Yes, its closed-cell structure acts as an effective built-in water vapor barrier, minimizing the risk of condensation and corrosion under insulation (CUI). - What is the thermal conductivity of HT/ArmaFlex?

The thermal conductivity (λ) at 40°C is typically ≤ 0.042 W/(m·K) for tubes and ≤ 0.045 W/(m·K) for sheets, ensuring good insulation performance. - Is HT/ArmaFlex a closed-cell material?

Yes, its closed-cell structure is key to its excellent water vapor resistance and thermal efficiency. - What is the fire performance classification of HT/ArmaFlex?

It typically achieves a Class 1 rating for surface spread of flame (BS 476 Part 7) and may have other classifications like Euroclass D-s3, d0. Always check the specific product datasheet. - Is HT/ArmaFlex oil-resistant?

Yes, it offers good resistance to oils, which is beneficial in various industrial applications. - In what forms is HT/ArmaFlex available?

It is available in tubes, sheets (rolls), and self-adhesive tapes to suit different insulation needs. - What are the typical applications for HT/ArmaFlex?

Common applications include solar thermal systems (including outdoor piping), hot gas lines, steam lines, dual-temperature lines, and automotive applications. - Is HT/ArmaFlex easy to install?

Yes, being flexible and fiber-free, it is easy to handle and install, often without special tools. ArmaFlex HT625 adhesive is recommended for reliable joints. - Does HT/ArmaFlex require additional jacketing for UV protection outdoors?

In most typical outdoor environments, HT/ArmaFlex’s inherent UV resistance eliminates the need for additional UV protective jacketing. However, extreme conditions might warrant further protection. - What are the benefits of using HT/ArmaFlex in solar thermal systems?

Its high-temperature resistance and UV stability make it ideal for the demanding conditions of solar collector piping, ensuring long-term efficiency and protection. - Does HT/ArmaFlex help prevent corrosion under insulation (CUI)?

Yes, the closed-cell structure and low water vapor permeability significantly reduce the risk of moisture ingress, a primary cause of CUI. - Is HT/ArmaFlex fiber and dust-free?

Yes, it is a clean and user-friendly material that does not produce dust or fibers during installation or in service. - What is the lifespan of HT/ArmaFlex in outdoor applications?

Due to its UV and weather resistance, HT/ArmaFlex offers a long service life in outdoor environments compared to standard elastomeric insulations. - Does HT/ArmaFlex remain flexible at high temperatures?

Yes, it is specifically designed to remain flexible even at its maximum service temperature of +150°C, preventing cracking and maintaining insulation integrity. - Where can I find the technical datasheet for HT/ArmaFlex?

The detailed technical datasheet, including specific performance data and fire ratings, is available on the Armacell website and will be accessible on Gitco-sa.com’s product page. - Why choose HT/ArmaFlex for high-temperature and outdoor insulation needs?

HT/ArmaFlex offers a reliable, long-lasting solution with exceptional UV resistance, high-temperature performance, and inherent condensation control, making it ideal for demanding applications where these properties are critical.

Choose HT/ArmaFlex from Gitco-sa.com, your authorized Armacell distributor in Saudi Arabia and Bahrain, for a reliable, high-performance insulation solution designed to excel in high-temperature environments with excellent UV resistance.

Brand

Armacell

| Property | Value / Assessment | Standard / Test method | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature range | |||||||||||

| Service temperature1,2 |

|

EN 14706, EN 14707, EN 14304 | |||||||||

| Thermal conductivity | |||||||||||

| Declared thermal conductivity |

|

EN ISO 13787, EN 12667, EN ISO 8497 | |||||||||

| Declared thermal conductivity |

|

EN ISO 8497, EN ISO 13787, EN 12667 | |||||||||

| Fire Performance and Approvals | |||||||||||

| Reaction to fire | D(L)-s3,d0 (tubes) D-s3,d0 (sheets, tape) |

EN 13501-1, EN ISO 11925-2, EN 13823 | |||||||||

| UL standards | |||||||||||

| UL 94 V-04 | Pass | IEC 60695-11-10 | |||||||||

| Fire performance | |||||||||||

| Practical fire behaviour | Self-extinguishing, does not drip, does not spread flames. | ||||||||||

| Others | Class 1 | BS 476 Part 7 | |||||||||

| Physical attributes | |||||||||||

| Dimensions and tolerances | In accordance with EN 14304, table 1. | EN 822, EN 823, EN 13467 | |||||||||

| Weather and UV resistance | |||||||||||

| UV resistance5 | Very good | EN ISO 4892-2 | |||||||||

| Health and environment | |||||||||||

| Volatile organic compounds (VOC) content | Fulfills all VOC requirements (French, Italian, Belgian, German AgBB, Blauer Engel and Eurofins Indoor Air Comfort GOLD). | ISO 16000 Parts 3, 6 & 9 | |||||||||

| Environmental Product Declaration (EPD) | Type III Environmental Product Declaration (EPD): Declaration number “EPD-ARM-20200222-IBA1-EN”, Institut Bauen und Umwelt e.V. (IBU) | ||||||||||

| Green building assessment | Meets the sustainable construction requirements for LEED v4.1, BREEAM international, WELL v2 and DGNB. | ||||||||||

| Additional features | SCCP, MCCP-free | ||||||||||

| Other technical features | |||||||||||

| AGI designation code | Tubes: 36.12.03.09.02 Sheets: 36.07.05.09.02 |

||||||||||

| Shelf life6 | Tape, self-adhesive: 1 year | ||||||||||

| Storage | Can be stored in dry, clean rooms at normal relative humidity (50% to 70%) and ambient temperature (0°C to 35°C). | ||||||||||

|

1For temperatures above +125 °C or below -50 °C, please contact our Customer Service Centre to request for the corresponding technical information. 2At high service temperatures, a certain hardening process may start on the inner surface of the material. Investigations have shown that these changes have no impact on the good physical and fire protection properties of the material, provided the material is installed in a correct way with all its joints properly sealed. For specific applications please consult our technical service. 3+85 °C, for products with a self-adhesive layer. 4Only for products without self-adhesive-layer. 5Extended exposure to certain conditions could result in aesthetic changes to insulation material. This includes examples such as minor discolouration, surface cracks or hardening of inner surface material due to extended exposure to high service line temperatures. These physical changes do not affect the technical performance of the insulation material, such as thermal conductivity and behaviour in case of a fire. For further information, please contact our Technical Service department. 6Shelf life (maximum storage time) is limited to ensure that only currently manufactured products are installed on projects. This limitation is restricted solely to storage of the product and does not affect the lifetime of product after it has been installed. |

|||||||||||

Datasheet

Reviews

There are no reviews yet.