HT/ArmaFlex Industrial: High-Temp Insulation for Oil & Gas

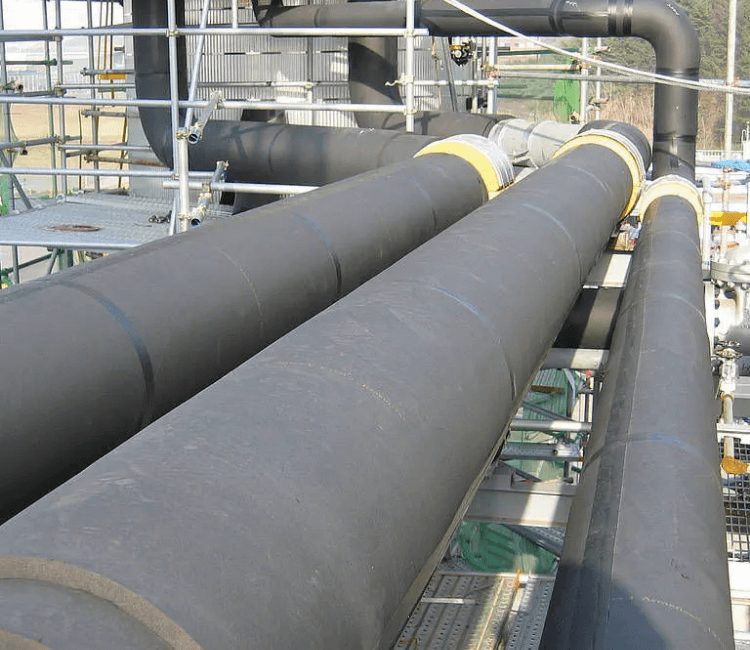

HT/ArmaFlex Industrial: Industrial-grade, high-density insulation designed for elevated temperatures in the oil and gas industry, featuring low thermal conductivity and reduced CUI risk. Industrial grade FEF insulation material designed for applications with elevated temperatures in the oil and gas industry. Available at Gitco-sa.com (authorized Armacell distributor in Saudi Arabia & Bahrain).

Description

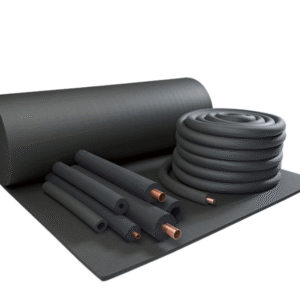

HT/ArmaFlex Industrial is a flexible, high-density, and mechanically robust closed-cell thermal insulation material based on extruded elastomeric foam (EPDM). Specifically developed for applications with elevated temperatures prevalent in the oil and gas industry, it offers enhanced thermal resistance with its low thermal conductivity. Gitco-sa.com is a trusted authorized distributor of Armacell products, including HT/ArmaFlex Industrial, in Saudi Arabia and Bahrain.

This industrial-grade insulation is designed for superior stability and is suitable for multi-layer applications, including ArmaSound Industrial Systems for acoustic insulation. Its built-in water vapor barrier significantly reduces the risk of corrosion under insulation (CUI), ensuring long-term performance and minimizing maintenance costs. HT/ArmaFlex Industrial retains its physical characteristics throughout its service life and features a low leachable chloride content (< 30 ppm) to minimize stress corrosion cracking (SCC).

Key Features of HT/ArmaFlex Industrial:

- Industrial Grade: Specifically designed for the demanding conditions of the oil and gas industry.

- High Temperature Resistance: Suitable for service temperatures from -50 °C (-58 °F) up to 125 °C (257 °F).

- Low Thermal Conductivity: Minimizes energy losses, enhancing system efficiency (λd ≤ 0.039 W/(m·K) at -50°C to ≤ 0.063 W/(m·K) at +125°C).

- Reduced CUI Risk: Built-in water vapor barrier minimizes corrosion under insulation.

- Mechanically Robust: High density for superior stability and durability.

- Multi-Layer Application: Compatible with ArmaSound Industrial Systems for acoustic solutions.

- Low Leachable Chlorides: Minimizes the risk of stress corrosion cracking (SCC).

- Self-Extinguishing: Does not drip or spread flames in case of fire.

- Low Water Absorption: Resists moisture ingress (≤ 0.1% by volume).

- Acoustic Performance: Contributes to noise reduction when used in ArmaSound systems.

Product Variations of HT/ArmaFlex Industrial:

HT/ArmaFlex Industrial is available in the following product range:

- Tubes: Available in thicknesses of 13mm, 19mm, and 25mm, suitable for pipe outer diameters ranging from 18 mm (⅜”) to 89 mm (3” NB).

- Sheets in Rolls: Available in thicknesses of 10mm, 13mm, 19mm, and 25mm. Standard roll width is 1 meter, with varying lengths depending on the thickness.

- Tube – standard Black, 13.0 mm nominal insulation thickness: HTI-13X018, HTI-13X022, HTI-13X028, HTI-13X035, HTI-13X042, HTI-13X048, HTI-13X054, HTI-13X060, HTI-13X076, HTI-13X089

- Tube – standard Black, 19.0 mm nominal insulation thickness: HTI-19X018, HTI-19X022, HTI-19X028, HTI-19X035, HTI-19X042, HTI-19X048, HTI-19X054, HTI-19X060, HTI-19X076, HTI-19X089

- Tube – standard Black, 25.0 mm nominal insulation thickness: HTI-25X015, HTI-25X022, HTI-25X028, HTI-25X035, HTI-25X042, HTI-25X048, HTI-25X054, HTI-25X060, HTI-25X076, HTI-25X089

- Tube – standard Black: HTI-10-99/E, HTI-19-99/E, HTI-13-99/E, HTI-25-99/3,5

Please contact Gitco-sa.com for specific part numbers, dimensions, and availability of HT/ArmaFlex Industrial variations in Saudi Arabia and Bahrain to meet your specific project needs.

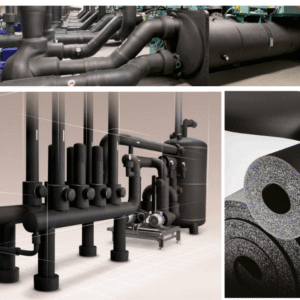

Applications of HT/ArmaFlex Industrial:

- Thermal insulation/protection of pipes, vessels, and ducts in:

- Offshore facilities

- Industrial plants (typically oil and gas)

- Process equipment facilities

- Component of ArmaSound Industrial Systems for acoustic insulation on industrial pipework and vessels.

HT/ArmaFlex Industrial – Frequently Asked Questions

HT/ArmaFlex Industrial is a high-temperature, flexible elastomeric foam insulation specifically engineered for industrial applications:

- What is HT/ArmaFlex Industrial?

HT/ArmaFlex Industrial is a closed-cell, flexible elastomeric foam insulation material based on EPDM (Ethylene Propylene Diene Monomer) rubber, designed for demanding industrial environments with elevated temperatures. - What is the maximum service temperature of HT/ArmaFlex Industrial?

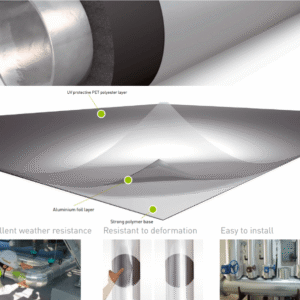

It can withstand continuous service temperatures ranging from -50°C up to +150°C. - Is HT/ArmaFlex Industrial suitable for outdoor use?

Yes, it is UV and weather-resistant, making it suitable for outdoor applications without requiring additional coverings in typical environments. However, extreme conditions may warrant protection. - Does HT/ArmaFlex Industrial have a built-in vapor barrier?

Yes, its closed-cell structure acts as an effective built-in water vapor barrier, reducing the risk of corrosion under insulation (CUI). - What is the thermal conductivity of HT/ArmaFlex Industrial?

The thermal conductivity (λ) at 40°C is typically ≤ 0.042 W/(m·K) for tubes and ≤ 0.045 W/(m·K) for sheets. - Is HT/ArmaFlex Industrial oil-resistant?

Yes, it offers good resistance to oils, which is beneficial in many industrial settings. - What is the fire performance classification of HT/ArmaFlex Industrial?

It typically achieves a reaction to fire classification of Class 1 (BS 476 Part 7) and Euroclass D-s3, d0 (EN 13501-1) for sheets and tubes. - Does HT/ArmaFlex Industrial produce burning droplets in case of fire?

No, it does not produce burning droplets in the event of a fire. - Is HT/ArmaFlex Industrial easy to install?

Yes, being flexible and fiber-free, it is easy to handle and install, often without the need for special tools. - What adhesive is recommended for use with HT/ArmaFlex Industrial?

ArmaFlex HT625 adhesive is specifically developed for reliable and secure bonding of HT/ArmaFlex seams and joints, suitable for high-temperature applications. - In what forms is HT/ArmaFlex Industrial available?

It is available in tubes of various sizes and thicknesses, as well as continuous sheets (rolls) in different thicknesses. Self-adhesive tapes are also available for sealing. - What are the typical applications for HT/ArmaFlex Industrial?

It is used for the thermal insulation of pipes, vessels, and ducts in industries such as solar panels (including outdoor installations), motor vehicles, hot gas lines, steam and dual-temperature lines. - Does HT/ArmaFlex Industrial contribute to energy savings?

Yes, its low thermal conductivity minimizes heat loss or gain, leading to improved energy efficiency of the insulated systems. - Is HT/ArmaFlex Industrial mechanically robust?

Yes, it is a high-density and mechanically robust material, providing superior stability for industrial applications. - Does HT/ArmaFlex Industrial have low leachable chloride content?

Yes, it has a low leachable chloride content (< 30 ppm), minimizing the risk of stress corrosion cracking (SCC). - Can HT/ArmaFlex Industrial be used in multi-layer applications?

Yes, it is suitable for use in multi-layer insulation systems, including ArmaSound Industrial Systems for acoustic insulation. - Does HT/ArmaFlex Industrial require any additional vapor barrier coverings?

No, due to its closed-cell structure, it typically does not require additional vapor barrier coverings. - What are the storage recommendations for HT/ArmaFlex Industrial?

It should be stored indoors in clean, dry conditions, away from direct sunlight, with a maximum shelf life of 3 years. - Is HT/ArmaFlex Industrial environmentally friendly?

It contains no CFCs, HCFCs, or PVC and has a Type III Environmental Product Declaration (EPD), indicating its environmental performance. - Where can I find the technical datasheet for HT/ArmaFlex Industrial?

The technical datasheet, including detailed specifications and performance data, is available on the Armacell website and potentially on Gitco-sa.com’s product page.

For reliable, high-performance insulation in demanding industrial environments, choose HT/ArmaFlex Industrial from Gitco-sa.com, your authorized Armacell distributor in Saudi Arabia and Bahrain.

Brand

Armacell

| Property | Value / Assessment | Standard / Test method | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature range | ||||||||||||||||||||||||||

| Service temperature1 |

|

EN 14706, EN 14707, EN 14304 | ||||||||||||||||||||||||

| Thermal conductivity | ||||||||||||||||||||||||||

| Declared thermal conductivity |

|

EN ISO 13787, EN 12667, EN ISO 8497 | ||||||||||||||||||||||||

| Fire Performance and Approvals | ||||||||||||||||||||||||||

| Reaction to fire | D-s3,d0 / D(L)-s3,d0 | EN 13501-1, EN 13823, EN ISO 11925-2 | ||||||||||||||||||||||||

| Surface burning characteristics | Class A, <25 Flame Spread Index | ASTM E84 | ||||||||||||||||||||||||

| Surface flammability2,3 | IMO Part 5 | IMO 2010 FTP Code, Part 5 | ||||||||||||||||||||||||

| Fire performance | ||||||||||||||||||||||||||

| Practical fire behaviour | Self-extinguishing, does not drip, does not spread flames. | |||||||||||||||||||||||||

| Resistance to water | ||||||||||||||||||||||||||

| Water absorption2 | ≤ 0.1% by volume (total submersion for 2 hours) | ASTM C209 | ||||||||||||||||||||||||

| Water absorption by vacuum | ≤ 4% by mass (total submersion for 2 x 180 seconds, vacuum pressure 17.2 kPa or 2.5 psi) | ASTM D1056 | ||||||||||||||||||||||||

| Corrosion mitigation | ||||||||||||||||||||||||||

| Leachable (water-soluble) chlorides | ≤ 30 ppm (mg/kg or µg/g) | EN 13468, ASTM C8715 | ||||||||||||||||||||||||

| pH-value2 | 7 to 9 | ISO 10523 | ||||||||||||||||||||||||

| Stress corrosion cracking2,6 | No cracks under magnifying glass on test coupons after evening, cleaning and rebending. | ASTM C692 | ||||||||||||||||||||||||

| Physical attributes | ||||||||||||||||||||||||||

| Density | Sheets: 70 to 85 kg/m³ (4.4 to 5.3 lb/ft³) Tubes: 60 to 75 kg/m³ (3.7 to 4.7 lb/ft³) |

ISO 845, ASTM D1622 | ||||||||||||||||||||||||

| Dimensions and tolerances | According to EN 14304, for detailed values, please refer to product range tables. | EN 822, EN 823, EN 13467 | ||||||||||||||||||||||||

| Mechanical properties | ||||||||||||||||||||||||||

| Tear strength | ≥0.4 kNm (≥2.3 lbf/in) | ISO 34-17 | ||||||||||||||||||||||||

| Compression deflection | ||||||||||||||||||||||||||

| Compression deflection 25% | ≥ 15kPa (≥ 2.2 psi) at 25% deflection | ISO 6916-18 | ||||||||||||||||||||||||

| Acoustic performance | ||||||||||||||||||||||||||

| System acoustic insertion loss | When used as part of a system: HT/ArmaFlex Industrial complies to ISO 15665 Classes A to C and Shell DEP 31.46.00.31-Gen Class D. Minimum acoustic service temperature (interface temperature to pipework or underlying thermal insulation layers) is -40 °C (-40 °F). | ISO 3741, ISO 156659 | ||||||||||||||||||||||||

| Weather and UV resistance | ||||||||||||||||||||||||||

| Weather resistance | In all industrial applications, the outer layer of the material must be protected with an adequate covering like Arma-Chek R, metal jacketing or preformed UV-cured Glass-Reinforced Plastic (GRP) cladding. For further information, please contact Technical Services. | |||||||||||||||||||||||||

| Health and environment | ||||||||||||||||||||||||||

| Health aspects | Neutral, SDS available on request. | |||||||||||||||||||||||||

| Other technical features | ||||||||||||||||||||||||||

| Adhesion and sealing10,11 | ArmaFlex HT625 adhesive should be used for reliable adhesion of joints and seams. HT/ArmaFlex tape can be used for application. | |||||||||||||||||||||||||

| Application conditions12,13 | Application temperature should be maintained at +5°C to +35 °C (+41°F to +95°F) and at a maximum relative humidity of 80%. | |||||||||||||||||||||||||

| Closed-cell content | ≥ 90% (declared on the basis of the water absorption test.) | |||||||||||||||||||||||||

| Shelf life14 | Maximum of 3 years. | |||||||||||||||||||||||||

| Storage | Material shall be stored indoors, in clean and dry conditions, away from direct sunlight. | |||||||||||||||||||||||||

|

1 For use in temperatures beyond the published value, please contact Technical Services. 2 Based on single test results. Can be used for information / reference only. 3 Meets the criteria of floor coverings and primary deck coverings. 4 For further information regarding water vapour transmission resistance, please contact Technical Services. 5 Specimen prepared according to EN 13486: neither cut, ground nor blended. Test temperature +100°C, leaching time 0.5 hours as specified in the standard for product maximum service temperature. 6 The coupons from type 304 stainless steel, 1.5 mm thick. 28 days drip test using deionized or distilled water at around +100°C. 7 Minimum value in Machine Direction (MD) and in Cross Direction (CD). Method B, procedure (b), angle test piece with a nick. 8 Equivalent method to ASTM D1056. 9 Equivalent method to ASTM E1222. 10 During storage of the product, blooming on the surfaces may occur. This blooming does not affect the technical properties of the material, but can affect the adhesion properties. Therefore, the surface needs to be cleaned (wiped off) before adhesives can be applied. 11 For further information, please contact our Customer Service. 12 For environmental conditions outside the given range, please contact Technical Services. 13 Application temperature (temperature of installation) refers to the ambient temperature during application and the surface temperature of the substrate to which the product is installed. 14 Shelf life (maximum storage time) is limited to ensure that only currently manufactured products are installed on projects. This limitation is restricted solely to the storage of the product and does not affect the lifetime of product after it has been installed. |

||||||||||||||||||||||||||

Reviews

There are no reviews yet.