Rigid Polyurethane Foam, PUR foam pipe insulation

Rigid Polyurethane Foam, PUR foam pipe insulation is a highly efficient, closed-cell material offering superior thermal insulation for industrial piping. This new thermal insulation material is recognized as one of the best isolation products for saving energy and maintaining temperature stability. Gitco-sa.com supplies a complete range of this high quality insulation across Saudi Arabia.

Description

Rigid Polyurethane Foam, PUR foam pipe insulation is a new thermal insulation material characterized by its extremely low thermal conductivity (λ-value, typically ≤ 0.027 W/(m.K)). Formed into rigid, pre-fabricated pipe sections, PUR foam is a closed-cell polymer that significantly outperforms traditional insulants like mineral wool and expanded polystyrene in thermal efficiency.

This high efficiency means less thickness is required to achieve the necessary thermal resistance (R-value), offering a space-saving solution for industrial and commercial pipework. The rigidity of the material provides excellent dimensional stability and moderate compressive strength, allowing it to withstand external pressures and maintain insulation integrity over time.

Key features of PUR foam pipe insulation include:

-

High Thermal Efficiency: Minimizes heat loss in hot lines and prevents temperature gain in chilled water systems, crucial for reducing operational costs in KSA.

-

Low Water Absorption: The closed-cell structure resists moisture ingress, mitigating the risk of material degradation and system failure.

-

Ease of Installation: Supplied in pre-cut halves or segments that fit quickly and snugly around pipes, reducing labor time on site.

-

Versatility: Effective across a wide temperature range, typically from -20 °C up to +130 °C.

The Complete Range of PUR Foam Pipe Insulation

Gitco-sa.com provides a complete range of these high quality PUR foam products, tailored for diverse industrial and commercial needs:

-

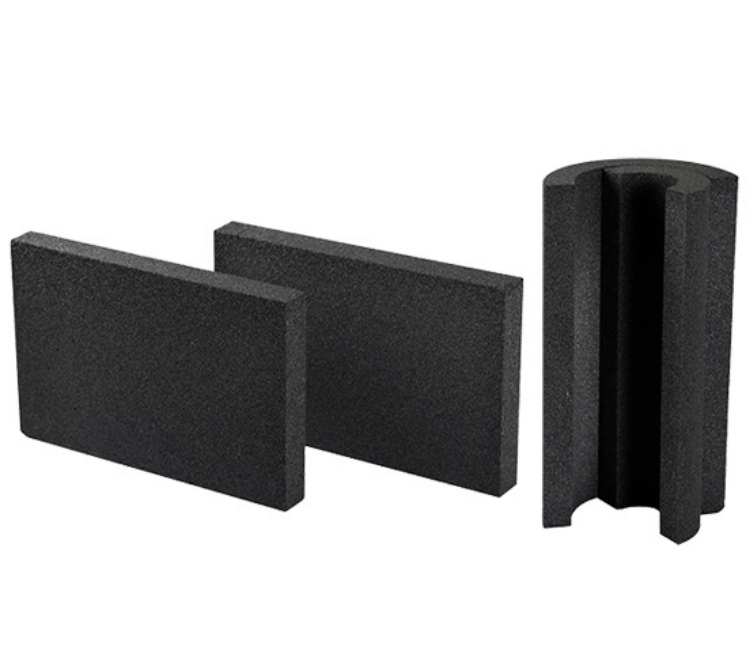

Pre-formed Pipe Sections: Available in half-round sections to match all standard pipe sizes (NPS) and diameters, ensuring a precise fit and continuous insulation layer.

-

Blocks and Boards: Supplied as high-density blocks for insulating large flat surfaces, complex valve/flange boxes, and specific equipment geometry.

-

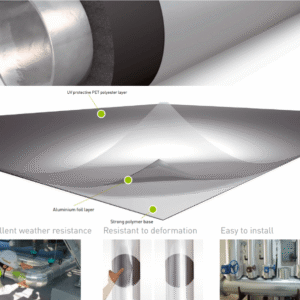

Integrated Vapor Barrier: Pipe sections can be supplied with an external factory-applied facing (e.g., reinforced aluminum foil or glass cloth) to act as a vapor barrier, which is essential for cold insulation systems to prevent condensation.

-

Density Variations: Available in various densities to meet specific compressive strength requirements, ensuring the insulation is robust enough for high-traffic or heavily jacketing areas.

We guarantee that our Rigid Polyurethane Foam Pipe Insulation materials are the best isolation products for achieving maximum energy savings and system performance. Gitco-sa.com ensures the complete range is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications of PUR Foam Pipe Insulation

-

Chilled Water (CHW) Lines: Insulation for HVAC chilled water and air-conditioning systems in commercial buildings, hospitals, and hotels.

-

Hot Water and Steam Tracing: Used in industrial settings to insulate medium-temperature process piping, domestic hot water lines, and light steam lines.

-

Oil & Gas Industry: Insulation for non-cryogenic process piping and heat exchangers where energy conservation is critical.

-

Refrigeration Systems: Insulating lines in cold storage facilities and industrial freezers.

Know more about PUR Foam Pipe Insulation:

1. Product Identity and Composition

- What is Rigid Polyurethane (PUR) foam pipe insulation?

It is a lightweight, high-performance, closed-cell foam insulation material supplied in pre-formed half-sections or segments, specifically designed to fit around industrial or commercial pipes.

- What is the chemical composition of PUR foam?

It is formed by the reaction of a polyol and an isocyanate, along with catalysts and a blowing agent, creating a stable, rigid cellular structure.

- How is PUR different from PIR (Polyisocyanurate) in this application?

While similar, PUR foam is characterized by a lower ratio of isocyanate compared to PIR, giving it a different fire performance profile and slightly different maximum operating temperature limits.

- What does the “closed-cell” structure imply for its performance?

The closed-cell structure ensures that the foam is highly resistant to moisture ingress and water vapor transmission, which is critical for maintaining its insulating effectiveness over time.

- Is PUR foam pipe insulation typically supplied with a facing?

Yes, it is often supplied with an external protective covering or facing, such as a Kraft paper/aluminum foil laminate (Vapor Barrier Facing, VBF) or a heavier metal jacketing (Aluminum, Stainless Steel) for mechanical protection.

2. Thermal Performance and Efficiency

- What is the key advantage of PUR foam in terms of thermal efficiency?

PUR foam has one of the lowest thermal conductivity (λ) values among common insulation materials, typically ranging from 0.025 to 0.030 W/(m·K), ensuring minimal heat loss or gain.

- What is the main application for PUR in terms of temperature?

It is primarily used for cold insulation systems, such as chilled water lines, refrigeration piping, and cold storage applications, due to its excellent thermal performance at low temperatures.

- What is the typical operating temperature range for standard PUR insulation?

Standard PUR pipe insulation is suitable for a wide range, typically from -50 °C up to +110 °C or 12$+120 °C.

- How does the low thermal conductivity impact energy costs?

Its high efficiency minimizes energy usage required to maintain the fluid temperature in the pipe, leading to significant long-term energy cost savings.

- Does PUR maintain its thermal properties in humid environments?

Yes, its closed-cell structure ensures that the material’s thermal properties remain stable even in environments with high humidity, unlike open-cell or fibrous materials.

3. Structural and Fire Properties

- Does PUR pipe insulation offer good compressive strength?

Yes, rigid PUR foam possesses good to moderate compressive strength, which helps the pipe maintain its shape and resist crushing, especially under light foot traffic or external pressure.

- What fire rating does standard PUR typically achieve?

Standard PUR is considered flammable but often self-extinguishing when the ignition source is removed, and it is usually required to comply with specific fire standards (e.g., meeting requirements like ASTM E84).

- Are there PUR foam variants with improved fire resistance?

Yes, when higher fire resistance is required, Polyisocyanurate (PIR), which is chemically related to PUR, is often specified, as it offers superior fire and smoke performance.

- Is PUR foam susceptible to water absorption?

No, due to its closed-cell nature, the material has a very low water absorption rate (typically less than 1% by volume), which is crucial for preventing insulation failure.

- What is the density range for typical PUR pipe insulation?

Standard insulation densities usually range from 35 to 60 kg/m³ (2.2 to 3.7 lb/ft³).

4. Installation and Sourcing

- How are the pre-formed sections installed on a pipe?

The half-sections are placed around the pipe, secured with bands or tape, and then the seams and joints are sealed with a vapor barrier sealant and mastic to ensure a continuous thermal and vapor-tight envelope.

- What is the required preparation for the pipe surface before insulation?

The pipe surface must be clean, dry, and free of any rust or contaminants to ensure the integrity of the vapor barrier system and prevent CUI (Corrosion Under Insulation).

- Is PUR used for insulating pipe fittings (elbows, tees)?

Yes, the foam is available in pre-molded shapes (segments or ‘quadrants’) to perfectly fit pipe fittings, minimizing gaps and maximizing thermal integrity at complex points.

- What is the typical lifespan of installed PUR insulation?

When properly installed, protected by a continuous vapor barrier, and maintained, PUR insulation is expected to provide reliable performance for the entire service life of the piping system.

- Is technical consulting necessary when specifying this material?

Yes, due to the critical nature of the vapor barrier in cold systems, engineering consultation is essential to determine the correct insulation thickness and specify the full installation system (including adhesives, mastics, and cladding).

Brand

Zhenshen Insulation

Zhenshen Insulation is a trusted global manufacturer recognized for delivering high-performance insulation solutions, particularly their advanced Cellular Glass (Foam Glass) products. As a supplier of Aramco and SABIC approved products, Zhenshen meets the rigorous quality, safety, and durability standards demanded by the largest industrial and energy corporations in the Kingdom of Saudi Arabia. All Zhenshen products comply with stringent ASTM standards, guaranteeing reliability for critical applications.

Zhenshen Cellular Glass Insulation (Foam Glass/Foamglas) is the cornerstone of their industrial offering, renowned for its:

-

Absolute Vapor Impermeability: The closed-cell structure makes it a definitive vapor barrier, preventing moisture migration and eliminating the risk of Corrosion Under Insulation (CUI), vital for long-term reliability in cold insulation and hot insulation systems.

-

Non-Combustibility: Being inorganic, it is inherently fireproof, providing a crucial safety layer in LNG tank, pipeline, and chemical processing environments.

-

High Compressive Strength: Its rigidity makes it ideal for high-load applications, including cryogenic tank bases and pipe supports, ensuring system integrity.

The Complete Range of Zhenshen Insulation Products

Gitco-sa.com supplies the complete range of high quality Zhenshen Insulation materials, ensuring compliance and availability for major projects:

-

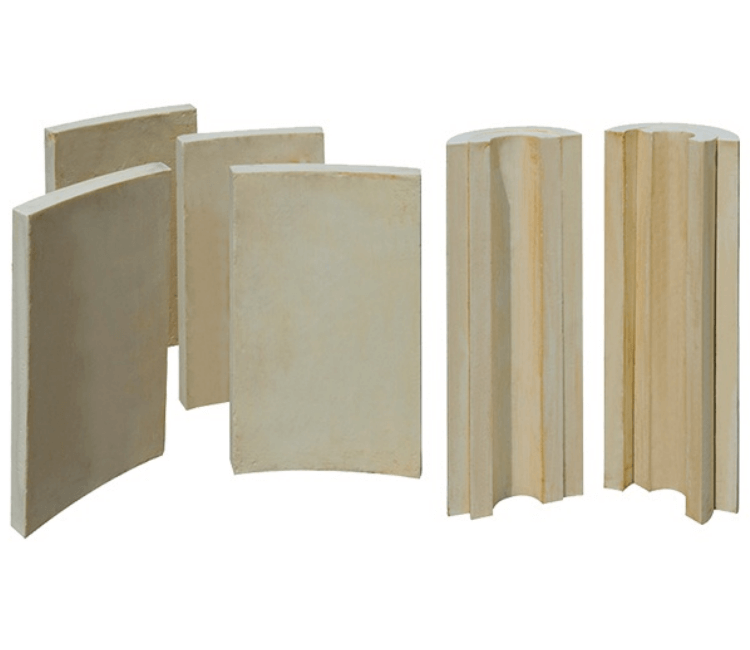

Cellular Glass Pipe Sections: Pre-formed insulation for pipeline insulation in LNG, cold, hot, and medium-temperature systems. Available for various pipe sizes and thicknesses, compliant with ASTM standards.

-

Foam Glass Slabs & Boards: Used for LNG tank bases (cryogenic systems), equipment, vessels, roof insulation, and wall insulation in industrial and commercial building insulation projects.

-

Tapered & Curved Sections: Custom Foam Glass segments for precise insulation of large vessels, tanks, and structural elements, ensuring thermal continuity.

-

Specialized Industrial Grades: Products engineered specifically for the extreme conditions found in petrochemical and hydrocarbon processing systems, carrying the distinction of being Aramco and SABIC approved products.

We guarantee that our Zhenshen Insulation products are the best isolation products for achieving maximum durability and safety. Gitco-sa.com ensures the complete range of these high quality, Aramco and SABIC approved materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications

-

Industrial/Energy: LNG tank and cryogenic tank insulation, pipeline insulation (hot and cold), and process equipment in Hydrocarbon Processing and Chemical Processing Systems.

-

Building & Construction: Roof insulation, wall insulation, and structural insulation for commercial and industrial buildings requiring high fire ratings and moisture control.

-

Waterproofing: Used in conjunction with construction and roofing materials due to its zero-permeability.

Reviews

There are no reviews yet.