Glass Fiber Resilient Blanket

The Glass Fiber Resilient Blanket is a high quality thermal and acoustic insulation material, lightweight and highly flexible. It is recognized as one of the best isolation products for effective heat retention and sound absorption in construction and HVAC systems. Gitco-sa.com provides a complete range across Saudi Arabia.

Description

The Glass Fiber Resilient Blanket is a semi-rigid or flexible roll insulation material composed of long, fine glass fibers bonded together using a thermosetting resin (often formaldehyde-free). The term “resilient” refers to the material’s ability to recover its original thickness after compression, ensuring that the intended air pockets—which provide the primary insulating mechanism—are consistently maintained.

This product is highly valued in the construction industry for its dual performance characteristics:

-

Superior Thermal Insulation: The trapped air within the structure creates a low thermal conductivity ( λ-value, typically around 0.032 W/(m.K)), dramatically reducing heat transfer, which is crucial for energy efficiency in the hot Saudi Arabian climate.

-

Excellent Acoustic Insulation: The open, resilient structure effectively dissipates sound energy, reducing noise transmission between rooms or from external sources.

-

Fire Performance: Inherently non-combustible due to the glass fiber base, enhancing fire safety in buildings.

-

Lightweight and Easy Handling: Its flexibility and low density make it simple to cut and install in tight spaces, significantly reducing labor time.

The Complete Range of Glass Fiber Resilient Blankets

Gitco-sa.com supplies a complete range of these high quality blankets, differentiated by density, facing, and specific application:

-

Standard Unfaced Rolls/Batts: Available in various thicknesses and densities (e.g., 10 kg m³

to 32 kg m³) for general thermal and acoustic infill in dry wall cavities, ceilings, and floors.

-

Foil-Faced Blankets: Features a factory-applied facing of aluminum foil (often reinforced) acting as an integrated vapor barrier and radiant barrier. This variation is essential for hot and humid climates like Dammam and Al-Khobar, preventing moisture condensation within the structure and reflecting heat.

-

Acoustic and HVAC Applications: Higher density options specifically manufactured for lining the interior of HVAC ducts (Duct Wrap) or serving as acoustic absorption layers behind perforated finishes in commercial spaces.

-

Custom Dimensions: Available in a complete range of widths and lengths to minimize waste and ensure full coverage in standard construction framing.

Key Applications of Glass Fiber Resilient Blanket:

-

Wall Insulation: Infill insulation for lightweight partition walls and curtain wall systems (internal and external) for acoustic and thermal separation.

-

Ceiling and Roof Insulation: Laying insulation over suspended ceilings, false ceilings, and between ceiling rafters for maximum heat control.

-

HVAC Systems: Used as Duct Wrap (external pipe/duct insulation) and Duct Liner (internal acoustic lining) to maintain temperature and reduce noise.

-

Acoustic Absorption: Installed in cinemas, studios, auditoriums, and commercial spaces to enhance internal sound quality.

We guarantee that our Glass Fiber Resilient Blankets are the best isolation products for combined thermal and acoustic performance. Gitco-sa.com ensures the complete range of these high quality materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Know more about Glass Fiber Resilient Blanket:

1. Product Identity and Composition

- What is a Glass Fiber Resilient Blanket?It is a lightweight, flexible thermal and acoustic insulation material made from fine, stable, and uniformly textured inorganic glass fibers (often containing recycled content) bonded with a thermosetting resin binder.

- What does the term “resilient” mean in this context?Resilience refers to the material’s ability to recover quickly to its original thickness and dimensions after being compressed, ensuring its thermal and acoustic performance is maintained over time and under load.

- What is the core component that gives the material its properties?The core component is the interwoven, air-laid network of glass fibers, which traps air within the structure, providing the primary thermal and acoustic resistance.

- Are these blankets available with different facings?Yes, they are available unfaced or laminated with various facings, such as FRK (Foil Reinforced Kraft), ASJ (All Service Jacket), or AWF (Aluminum Foil Woven Fiberglass), to act as a vapor barrier or provide a finished look.

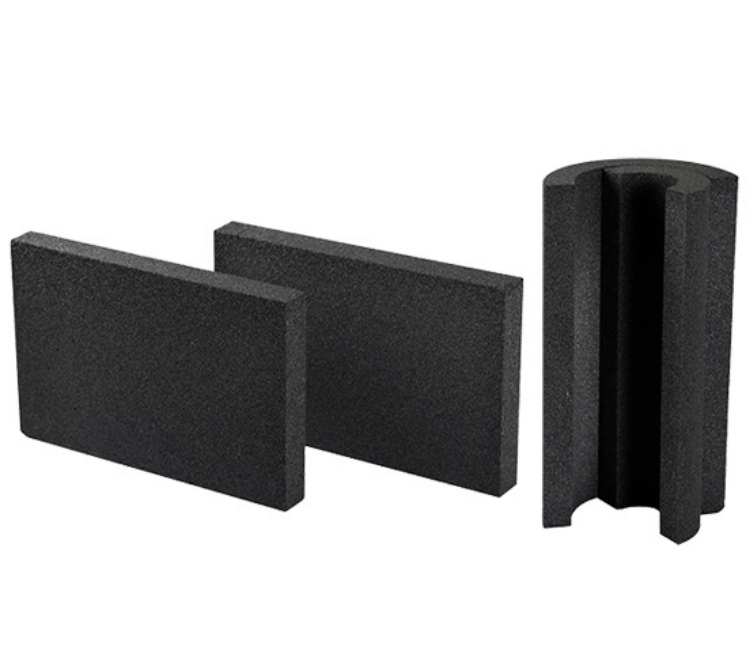

- What is the typical appearance of the blanket insulation?It is typically a golden yellow or brown color due to the resin binder, though some acoustic versions are made with a black finish.

2. Primary Applications and Use Cases

- What is a key industrial application for resilient glass fiber blankets?A critical application is in cryogenic storage tanks (e.g., for LNG, Liquid Natural Gas), where the blanket acts as an insulation layer in the double-wall system.

- What is the blanket’s role in cryogenic tanks?In cryogenic tanks, the blanket is placed at expansion/contraction joints to absorb the pressure changes and dimensional movement caused by extreme temperature fluctuations (as low as -170 °C), preventing damage to the main insulation.

- How is the blanket used in HVAC systems?It is used for the thermal and acoustic insulation of HVAC air ducts and plenums, where its resilience prevents settling and maintains the required R-value.

- In building construction, where are these blankets installed?They are commonly installed as insulation in walls (metal studs), roofs, ceilings (above suspended ceilings), and floors in commercial, industrial, and residential buildings.

- Is the blanket used for acoustic control?Yes, the blanket is a highly effective sound-absorbent material, often used in drywall partitions, sound boxes, and ductwork liners to achieve high NRC (Noise Reduction Coefficient) ratings.

3. Thermal and Mechanical Performance

- What is the typical density range for general-purpose blanket insulation?General-purpose densities typically range from 10 to 32 kg/m (0.6 to 2.0 pcf), depending on the application requirement.

- What is the thermal efficiency (low k-factor) of glass fiber blankets?They have a very low thermal conductivity (λ), often around 0.034 to 0.038 W/(m·K) at a mean temperature of 24 °C.

- What is the maximum operating temperature for standard glass fiber blankets?Standard blankets typically have a maximum operating temperature of around 232 °C (450°F), though industrial grades can withstand up to 538 °C or 1,000°F.

- How does the resilient blanket perform under vibration?The exceptional resiliency of the glass fibers prevents vibrational settling, ensuring the blanket maintains its thickness and thermal performance even in high-vibration applications like machinery or aircraft.

- What is the tensile strength of the material?The blanket is engineered for increased tensile strength, allowing it to support its own weight and resist separation during fabrication and installation, which is crucial for vertical applications.

4. Safety and Durability

- Is the base glass fiber material combustible?No, the base glass fiber is non-combustible and does not contribute to fire spread, typically meeting the highest fire standards (e.g., Euroclass A1 or ASTM E84/UL 723 Flame Spread Index ≤25).

- Is the material prone to corrosion?No, the inorganic, mineral composition of the material makes it chemically inert and will not cause or accelerate the corrosion of steel, stainless steel, copper, or aluminum (tested per ASTM C665).

- Does the blanket promote mold or fungal growth?No, the glass fibers are non-cellular, non-hygroscopic, and rot-proof, meaning they do not encourage or sustain the growth of mold, fungi, or bacteria.

- What is the typical water vapor sorption rate?The water vapor sorption is very low, typically less than 1% by weight (tested per ASTM C1104), ensuring the material remains dry and maintains its thermal efficiency.

- How is the blanket supplied to save on transport costs?Due to its high resilience, the blanket is often compression-packed in rolls to significantly reduce volume, saving on freight costs and storage space, but it fully recovers upon unpacking

Brand

Zhenshen Insulation

Zhenshen Insulation is a trusted global manufacturer recognized for delivering high-performance insulation solutions, particularly their advanced Cellular Glass (Foam Glass) products. As a supplier of Aramco and SABIC approved products, Zhenshen meets the rigorous quality, safety, and durability standards demanded by the largest industrial and energy corporations in the Kingdom of Saudi Arabia. All Zhenshen products comply with stringent ASTM standards, guaranteeing reliability for critical applications.

Zhenshen Cellular Glass Insulation (Foam Glass/Foamglas) is the cornerstone of their industrial offering, renowned for its:

-

Absolute Vapor Impermeability: The closed-cell structure makes it a definitive vapor barrier, preventing moisture migration and eliminating the risk of Corrosion Under Insulation (CUI), vital for long-term reliability in cold insulation and hot insulation systems.

-

Non-Combustibility: Being inorganic, it is inherently fireproof, providing a crucial safety layer in LNG tank, pipeline, and chemical processing environments.

-

High Compressive Strength: Its rigidity makes it ideal for high-load applications, including cryogenic tank bases and pipe supports, ensuring system integrity.

The Complete Range of Zhenshen Insulation Products

Gitco-sa.com supplies the complete range of high quality Zhenshen Insulation materials, ensuring compliance and availability for major projects:

-

Cellular Glass Pipe Sections: Pre-formed insulation for pipeline insulation in LNG, cold, hot, and medium-temperature systems. Available for various pipe sizes and thicknesses, compliant with ASTM standards.

-

Foam Glass Slabs & Boards: Used for LNG tank bases (cryogenic systems), equipment, vessels, roof insulation, and wall insulation in industrial and commercial building insulation projects.

-

Tapered & Curved Sections: Custom Foam Glass segments for precise insulation of large vessels, tanks, and structural elements, ensuring thermal continuity.

-

Specialized Industrial Grades: Products engineered specifically for the extreme conditions found in petrochemical and hydrocarbon processing systems, carrying the distinction of being Aramco and SABIC approved products.

We guarantee that our Zhenshen Insulation products are the best isolation products for achieving maximum durability and safety. Gitco-sa.com ensures the complete range of these high quality, Aramco and SABIC approved materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications

-

Industrial/Energy: LNG tank and cryogenic tank insulation, pipeline insulation (hot and cold), and process equipment in Hydrocarbon Processing and Chemical Processing Systems.

-

Building & Construction: Roof insulation, wall insulation, and structural insulation for commercial and industrial buildings requiring high fire ratings and moisture control.

-

Waterproofing: Used in conjunction with construction and roofing materials due to its zero-permeability.

Reviews

There are no reviews yet.