HDPIR High Density Pre-Insulated Pipe Supports for Cold Insulation System

HDPIR pipe supports (High Density Polyisocyanurate) are essential components in any cold insulation system. These supports prevent thermal bridging at pipe anchor points, offering high load capacity and superior thermal efficiency. Gitco-sa.com provides the complete range of these best isolation products across Saudi Arabia.

Description

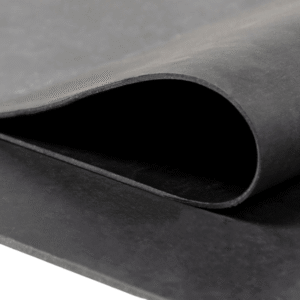

HDPIR High Density PIR Pipe Supports are specifically engineered rigid thermal blocks designed to bear the heavy weight of insulated pipework while maintaining the integrity of the cold insulation system. In cold applications (HVAC, refrigeration, petrochemicals), metal pipe clamps and hangers create a “thermal bridge” a direct path for heat transfer that causes massive energy loss and, critically, condensation or icing at the support point, leading to corrosion and system failure .

Our HDPIR pipe supports solve this problem by providing a structural layer with extremely low thermal conductivity (like a continuation of the main pipe insulation). Made from High Density Polyisocyanurate, the material offers exceptional compressive strength—significantly higher than standard PIR foam—ensuring stability under maximum load without crushing or deforming. They are recognized as the best isolation products for eliminating thermal bypass and guaranteeing a long, maintenance-free service life.

The Complete Range of HDPIR Pipe Supports

Gitco-sa.com provides the complete range of HDPIR supports, tailored to project size, temperature, and environment:

-

Standard HDPIR Blocks: Available in sizes to match all standard pipe diameters (DN 15 to over DN 600) and insulation thicknesses. The density is calibrated to match required compressive strength.

-

Integrated Casing Systems (High Quality): Supplied with an outer vapor barrier jacket and metallic casings (e.g., galvanized steel, stainless steel, or aluminum) pre-installed. These casings protect the HDPIR foam from external damage and moisture ingress, completing the cold insulation system barrier.

-

Load and Length Variations: Supports come in different lengths (e.g., 100 mm to 300 mm or custom lengths) depending on the load-bearing requirements, necessary for large-bore pipes or areas with high dynamic stress.

We guarantee that our HDPIR pipe supports are the best isolation products, delivering superior performance and fire safety characteristics (like standard PIR). Gitco-sa.com ensures the complete range of these high quality components is available for delivery and project consultation in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications of HDPIR Pipe Supports:

-

HVAC and Refrigeration: Isolating chilled water lines, air conditioning refrigerant pipes, and cold storage piping systems in commercial and industrial buildings.

-

Oil & Gas and Petrochemical: Used in cryogenic applications, LNG, ammonia, and ethylene pipelines where maintaining extremely low temperatures and preventing thermal bridging is mission-critical.

-

Industrial Process Cooling: Supporting piping used in manufacturing processes that require stable, low-temperature fluid transfer, especially those with high load demands.

Know more about HDPIR Pipe Supports:

1. Function and Necessity

- What is a pre-insulated pipe support?

It is a manufactured assembly that integrates a high-strength insulation material with a metal component (like a clevis hanger or structural shoe) designed to support pipework without breaking the continuous thermal envelope. - Why are they specifically essential in a cold insulation system (e.g., chilled water, cryogenic)?

They prevent thermal bridging (cold bridging), which is the direct path for heat transfer from the outside environment to the cold pipe, which would otherwise occur through a standard metal pipe support. - What is the primary risk if a standard metal support is used on a cold pipe?

A metal support acts as a high-conductivity path, causing the external surface of the support to drop below the dew point, leading to condensation, dripping, corrosion, and eventual failure of the entire insulation system. - What problem does HDPIR solve that traditional wood blocks failed to?

HDPIR provides a higher and more consistent compressive strength and superior, closed-cell moisture resistance compared to wood, which can rot, compress, or harbor mold. - How do these supports contribute to a cold insulation system’s overall vapor barrier integrity?

The HDPIR block is designed to be fully sealed and jacketed, and its mating surfaces with the main line insulation allow for the application of mastics and vapor barriers, ensuring a seamless, vapor-tight seal through the support location.

2. Material and Properties

- What does HDPIR stand for?

HDPIR stands for High-Density Polyisocyanurate foam. - How is HDPIR different from standard PIR foam insulation?

HDPIR is manufactured at a much higher density (e.g., 160 to 550 kg m³ ) than standard PIR (typically 35 to 40 kg m³ ), which significantly increases its compressive strength. - What is the typical compressive strength of HDPIR for pipe supports?

The compressive strength ranges widely based on density, but common specifications require a minimum of 2.0 MPa to over 12.0 MPa (Megapascals) at ambient temperature. - What is the thermal conductivity (λ) of HDPIR?

Despite the higher density, HDPIR maintains a low thermal conductivity, typically around ≤ 0.040 W/(m·K) at 20 °C for common densities, which is still excellent for insulation. - What is the typical service temperature range for HDPIR supports?

HDPIR has an exceptionally wide service temperature range, generally from -196 °C (cryogenic) up to +110 °C or +120 °C, making it highly versatile.

3. Applications and Design

- What types of systems are the primary applications for HDPIR pipe supports?

They are mainly used in petrochemical plants, liquefied gas (LNG/LPG) facilities, refrigeration houses, central air conditioning (chilled water), and food processing. - Do HDPIR pipe supports come in different functional categories?

Yes, they are designed for specific piping functions: Sliding supports, Guide supports, Limit/Fixing supports, and basic Insulation blocks. - Are HDPIR pipe supports typically single-layer or multi-layer?

For applications requiring thick insulation (e.g., 4 inches or greater), they are often supplied as multi-layered, stepped assemblies to improve the moisture seal and handle thermal contraction stresses. - Does HDPIR pipe support often include a metal load-bearing insert?

Yes, for very heavy loads, the HDPIR block is integrated into a metal shoe or saddle (often hot-dip galvanized or stainless steel) that includes a metal insert or sleeve to distribute the load directly from the pipe to the support hardware. - What auxiliary materials are supplied with HDPIR supports?

They are supplied with complementary materials such as a vapor barrier (e.g., Mylar foil/aluminum laminate), metal jacketing (e.g., Aluzinc), rubber sheets, and cryogenic mastics to ensure full system integrity.

4. Standards and Installation

- What industry standards govern the quality of HDPIR pipe supports?

They must comply with relevant industry standards such as ASTM C591 (for rigid cellular polyurethane insulation) and often reference dimensional standards like ASTM C585. - How are HDPIR supports typically installed on the pipe?

They are generally manufactured in two pre-molded halves (clamshell design) which are placed around the pipe, bonded together with adhesive, and then sealed at the joints with cryogenic mastic and the final vapor barrier. - What is the required preparation for the pipe surface before installing the support?

The pipe surface must be thoroughly cleaned (solvent cleaned for carbon steel) and sometimes prepared (roughened) to ensure proper adhesion of the specified adhesive/mastic to the inside of the support block. - What is the significance of the Closed Cell Content of HDPIR?

The closed-cell content is typically high (e.g., 95%), which directly limits water absorption and vapor permeability, preventing moisture-related insulation breakdown and maintaining the low thermal conductivity over time. - What is the typical method for packaging and storage?

Due to the critical nature of the material, supports are generally wrapped in anti-ultraviolet polythene film and then packed in sturdy wooden cases to protect them from damage and moisture ingress during transport and storage.

Brand

Zhenshen Insulation

Zhenshen Insulation is a trusted global manufacturer recognized for delivering high-performance insulation solutions, particularly their advanced Cellular Glass (Foam Glass) products. As a supplier of Aramco and SABIC approved products, Zhenshen meets the rigorous quality, safety, and durability standards demanded by the largest industrial and energy corporations in the Kingdom of Saudi Arabia. All Zhenshen products comply with stringent ASTM standards, guaranteeing reliability for critical applications.

Zhenshen Cellular Glass Insulation (Foam Glass/Foamglas) is the cornerstone of their industrial offering, renowned for its:

-

Absolute Vapor Impermeability: The closed-cell structure makes it a definitive vapor barrier, preventing moisture migration and eliminating the risk of Corrosion Under Insulation (CUI), vital for long-term reliability in cold insulation and hot insulation systems.

-

Non-Combustibility: Being inorganic, it is inherently fireproof, providing a crucial safety layer in LNG tank, pipeline, and chemical processing environments.

-

High Compressive Strength: Its rigidity makes it ideal for high-load applications, including cryogenic tank bases and pipe supports, ensuring system integrity.

The Complete Range of Zhenshen Insulation Products

Gitco-sa.com supplies the complete range of high quality Zhenshen Insulation materials, ensuring compliance and availability for major projects:

-

Cellular Glass Pipe Sections: Pre-formed insulation for pipeline insulation in LNG, cold, hot, and medium-temperature systems. Available for various pipe sizes and thicknesses, compliant with ASTM standards.

-

Foam Glass Slabs & Boards: Used for LNG tank bases (cryogenic systems), equipment, vessels, roof insulation, and wall insulation in industrial and commercial building insulation projects.

-

Tapered & Curved Sections: Custom Foam Glass segments for precise insulation of large vessels, tanks, and structural elements, ensuring thermal continuity.

-

Specialized Industrial Grades: Products engineered specifically for the extreme conditions found in petrochemical and hydrocarbon processing systems, carrying the distinction of being Aramco and SABIC approved products.

We guarantee that our Zhenshen Insulation products are the best isolation products for achieving maximum durability and safety. Gitco-sa.com ensures the complete range of these high quality, Aramco and SABIC approved materials is available for delivery and project support in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Key Applications

-

Industrial/Energy: LNG tank and cryogenic tank insulation, pipeline insulation (hot and cold), and process equipment in Hydrocarbon Processing and Chemical Processing Systems.

-

Building & Construction: Roof insulation, wall insulation, and structural insulation for commercial and industrial buildings requiring high fire ratings and moisture control.

-

Waterproofing: Used in conjunction with construction and roofing materials due to its zero-permeability.

Reviews

There are no reviews yet.