Rock Wool Cavity Panels at the Lowest Price in KSA

Rockwool Cavity Panels are high-performance, non-combustible insulation boards engineered for superior thermal and acoustic performance in walls and other building cavities. With a complete range of options and budget-friendly prices, Gitco-sa.com offers the lowest prices for Cavity Panels in Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and across Saudi Arabia.

Description

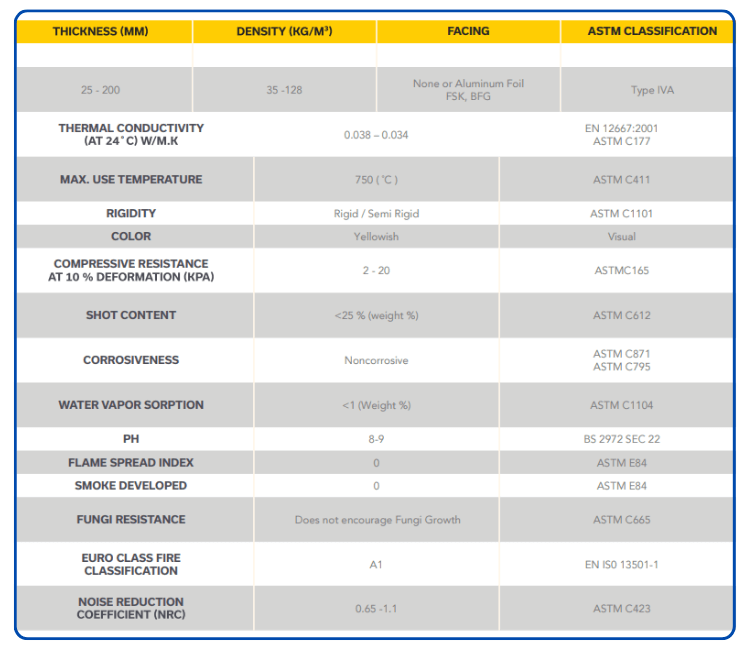

Rockwool Cavity Panels are rigid and semi-rigid insulation slabs made from molten basalt rocks that are spun into fine fibers and bonded with a thermosetting binder. This advanced manufacturing process results in a material with excellent thermal, fire-resistant, and acoustic properties. The panels are classified with a Euro Class Fire Classification of A1 , meaning they are non-combustible and will not contribute to a fire. Their thermal conductivity ranges from 0.038 to 0.034 W/m.K at 24°C, providing an effective barrier against heat transfer.

Acoustically, Cavity Panels are highly effective, with a Noise Reduction Coefficient (NRC) between 0.65 and 1.1, significantly reducing sound transmission and improving indoor comfort. The product is also noncorrosive and does not encourage fungi growth, ensuring long-term durability and a healthy environment. Gitco-sa.com provides a complete range of Rockwool Cavity Panels, with variations in thickness from 25 mm to 200 mm and densities from 35 kg/m³ to 128 kg/m³. They are also available with various facings, including none, Aluminum Foil, FSK, or BFG, to suit specific project requirements.

Key Applications of Rockwool Cavity Panels:

- Building Cavities: Ideal for filling voids in external and internal walls for thermal and acoustic insulation.

- Partitions and Drywall: Enhances the fire rating and soundproofing of partitions in commercial and residential buildings.

- HVAC and Industrial: Used as an effective insulation material for ducts, plenums, and other HVAC components, as well as industrial equipment and piping.

- Acoustic Control: Perfect for use in theaters, studios, and other spaces where high-quality sound absorption is critical.

We are committed to providing the best value, and our Cavity Panels prices are the lowest for Cavity Panels products, making them a budget-friendly solution for your projects. We offer a complete range and fast delivery to Dammam, Al-Khobar, Al Jubail, Riyadh, Jeddah, and all over Saudi Arabia, Bahrain, and the UAE.

Know more about Rockwool Cavity Panels:

1. Product & Composition

- What are Rockwool Cavity Panels?

They are rigid or semi-rigid insulation slabs made from molten basalt rock spun into fibers and bonded with a thermosetting resin. They are designed for insertion into the cavities of building walls and floors. - What are the primary uses of these panels?

They are primarily used for thermal, acoustic, and fire insulation in building cavities, particularly in masonry or timber frame cavity walls, partitions, and floor systems. - How are they installed in a cavity wall?

The panels are friction-fitted or mechanically fastened into the space between the inner and outer layers of a cavity wall. They are designed to fit snugly to ensure there are no gaps that could compromise insulation performance. - Are they a fire-rated product?

Yes, rock wool is inherently non-combustible. Rockwool Cavity Panels are classified as Euroclass A1, the highest fire safety rating, meaning they will not burn and do not contribute to fire spread or toxic smoke. They have a melting point exceeding 1000 °C. - Do they provide soundproofing?

Yes, the high density and fibrous, open-cell structure of the panels make them excellent for sound absorption. They have a high Noise Reduction Coefficient (NRC), typically ranging from 0.7 to 1.0, which helps reduce both airborne and impact noise. - What is the thermal conductivity (k-value)?

The thermal conductivity is typically very low, ranging from 0.034 to 0.038 W/mK, which makes them highly effective at reducing heat transfer and improving the energy efficiency of a building. - Do they have any moisture resistance?

Yes, the panels are naturally water-repellent. Their inorganic fibers do not absorb moisture, preventing the growth of fungi, mold, or bacteria, which is crucial for maintaining a healthy indoor environment. - What are the standard sizes and densities available?

The panels are commonly available in dimensions of 1.2 meters x 0.6 meters, with densities ranging from 40 to 100 kg/m³. Different densities are chosen based on the specific thermal and acoustic requirements of the project. - Are there different types of facings available?

Yes, they can be supplied with or without facings. Common facing options include Aluminum foil, black fiberglass veil (BFG), or polyethylene bags for added protection and vapor control. - Do they corrode metal pipes or wires?

No, Rockwool is non-corrosive. It has a neutral pH level and will not react with or cause rust on metals that it comes in contact with.

2. Benefits & Comparison

- What are the main benefits of using these panels?

Key benefits include:- Exceptional energy efficiency and reduced utility bills.

- Superior fire safety and passive fire protection.

- Excellent acoustic comfort and noise reduction.

- Durability and longevity, as they do not settle or shrink over time.

- Resistance to moisture and biological growth.

- How does rock wool compare to fiberglass insulation?

Rock wool generally offers superior fire resistance (higher melting point), better sound dampening (higher density), and is often considered a more robust material. Fiberglass can be more prone to moisture absorption and is less fire-resistant. - Is it suitable for use in high-temperature applications?

Yes, with a maximum service temperature of up to 750 °C, these panels can be used for a variety of high-temperature applications beyond standard building insulation. - Are they considered a sustainable building material?

Yes. Rock wool is made from an abundant natural resource (volcanic rock), and its long-term thermal performance significantly reduces a building’s energy consumption, leading to a massive reduction in its overall carbon footprint. - Does the product shrink or settle over time?

No, the semi-rigid to rigid structure of the panels ensures they are dimensionally stable. They will not settle, shrink, or slump over the life of the building, maintaining their thermal and acoustic performance.

3. Standards & Sourcing

- What international standards do they comply with?

Rockwool Cavity Panels are manufactured to meet stringent international standards, including ASTM C-612 and EN 13162, ensuring quality and performance. - What is the significance of the ASTM C612 classification?

This standard specifies the requirements for mineral fiber block and board thermal insulation, confirming the product’s quality for applications like building cavities, partitions, and equipment insulation. - Where are these panels manufactured?

Rockwool Cavity Panels are a “Saudi-made” product, manufactured in the Kingdom of Saudi Arabia. - Where can a user purchase these panels in Saudi Arabia?

Rockwool, a company like Gitco would be a primary supplier, providing access to these panels for projects in the GCC region. - Is there a price difference based on density?

Yes, the price of the panels is directly related to their density and thickness. Higher-density panels, which provide greater thermal and acoustic performance, typically come at a higher cost per panel.

Reviews

There are no reviews yet.